What You Need to Know About CNC Lathe Machines

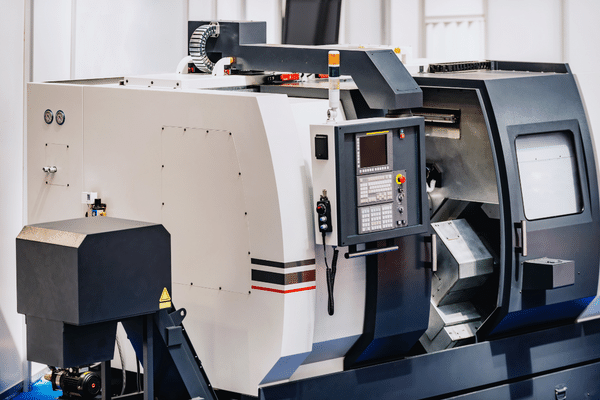

A CNC lathe machine is a computer numerical controlled (CNC) machine that can be used to create precision parts with an automated process. CNC lathes are highly accurate and can produce complex shapes, such as threaded components, in a fraction of the time it would take a manual machinist. They also produce parts with repeatable accuracy and high production yields. This makes them ideal for manufacturers who need to produce large quantities of parts with exacting tolerances quickly.

How Does a CNC Lathe Work?

A CNC lathe works by using a series of programmed instructions that direct the movement of the cutting tool along an axis, usually on a rotating workpiece. The instructions for the machine are typically written in a programming language specific to the particular machine being used and may require some expertise to execute properly. Once the program has been written, it can be loaded into the machine’s memory and executed automatically.

The Benefits of CNC Lathe Machines

CNC lathes offer several advantages over traditional manual machining operations. For one, they allow for higher accuracy and repeatability than manual machines do, as they can automatically adjust settings such as speed and feed rate according to pre-programmed instructions. Additionally, because they are automated, they require less labor, which can lead to lower labor costs overall. Finally, since they rely on computerized control systems, they tend to be more reliable than manual machines and require less maintenance overall.

The Drawbacks of CNC Lathe Machines

As with any technology, there are certain drawbacks associated with using CNC lathes that buyers should consider before investing in one. For one, these machines tend to be more expensive than their manual counterparts due to their sophisticated control systems and advanced features like 3D printing capability or laser engraving capabilities.

Additionally, while these machines offer greater accuracy than manual machines, their accuracy level is still limited by factors such as material hardness and surface finish quality. Furthermore, operating these machines requires specialized knowledge that may not always be readily available within an organization’s existing workforce.

In conclusion, CNC lathe machines offer many benefits over traditional manual machining operations such as higher accuracy and repeatability rates and lower labor costs overall. However, buyers should also consider potential drawbacks like costliness or specialized knowledge requirements when deciding whether to invest in this type of equipment for their manufacturing needs.

When done correctly, utilizing the right equipment can help streamline processes, allowing for greater efficiency within your business operations. Investing in quality machinery like a CNC lathe is often considered worth it in the long run for those looking for increased productivity from their manufacturing facility!

An Introduction to CNC Lathe Machines and Their Components

A CNC lathe machine is an automated, computer-controlled lathe used for machining parts and components. The machine consists of different sub-systems that work together to allow it to perform complex operations with high precision and accuracy. In this article, we’ll discuss the parts of a CNC lathe machine and how they work together.

The Main Components of a CNC Lathe Machine

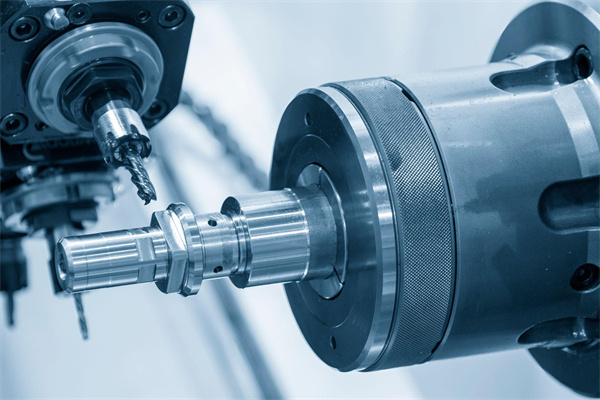

A CNC lathe consists of several main components that are essential for its operation. The first component is the spindle, which is the rotating part of the machine that holds the cutting tool. The spindle is driven by a motor and speed control system, which can be adjusted to accommodate various cutting operations. Additionally, a CNC controller or computer numerical control (CNC) unit controls all aspects of the machine’s movements such as feed rate, spindle speed, position data, tooling parameters, and more. Another important component is the bed or base on which the other components are mounted. This provides stability during machining operations and also serves as a platform for mounting additional components such as clamps and coolant systems.

Additional Components That Make Up A CNC Lathe Machine

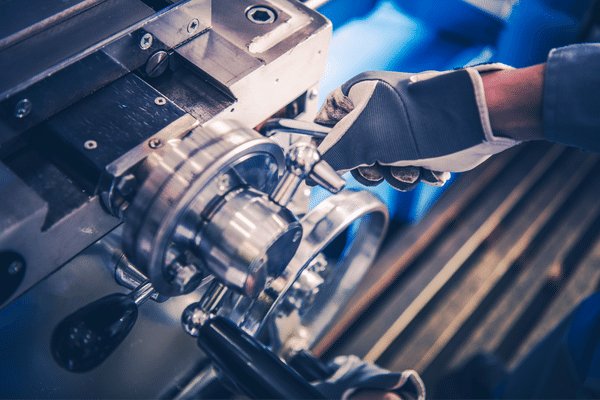

In addition to the main components mentioned above, several additional components make up a CNC lathe machine. These include carriage assemblies which provide support for tools during cutting operations; tailstocks which hold material in place while it is being cut; chucks which hold material during turning processes; steady rests which provide additional support when machining long materials; live centers which reduce vibration when machining cylindrical materials; and other specialty tools such as drill bits, reamers, taps, etc., used for specific machining tasks. Furthermore, coolant systems are necessary to cool down the workpiece during cutting operations to ensure accuracy and extend tool life.

A CNC lathe machine is an invaluable tool in any modern manufacturing plant due to its ability to produce intricate parts with high precision in minimal amounts of time. The parts discussed above play an important role in allowing these machines to perform their tasks effectively and efficiently while minimizing downtime and costs associated with manual labor or traditional metalworking methods. With proper maintenance and upkeep, these machines can be relied upon year after year to produce accurate results quickly and cost-effectively—making them an ideal choice for any business looking for reliable machining services with minimal effort required from their operators or technicians.

Different Types of CNC Lathe Machines for Machining Buyers

When it comes to machining, CNC (Computer Numerical Control) lathe machines are the standard. But did you know that there are several different types of CNC lathe machines that can be used to produce different results? In this blog post, we’ll discuss the various types of CNC lathes available and provide tips on choosing the right machine for your needs.

The Most Common Types of CNC Lathes

The most common type of CNC lathe is the vertical turning center. This type of machine has a stationary spindle that rotates around a vertical axis. These machines are typically used for heavy-duty cutting and drilling operations, such as boring and reaming operations. They are also capable of producing high-precision parts with tight tolerances.

Another popular type of CNC lathe is the horizontal turning center. This type of machine has a rotating spindle that spins around a horizontal axis. These machines are often used for precision tasks, such as threading and machining intricate parts with complex shapes and tight tolerances. They can also be used for more general machining tasks, such as drilling, tapping, facing, and milling operations.

A third type of CNC lathe is the combination turning center (or multi-axis turning center). As its name suggests, this machine combines vertical and horizontal axes in one unit. These machines offer more flexibility than traditional single-axis machines because they can perform multiple operations in one setup—such as drilling, boring, reaming, threading, milling, and cutting—at once. This makes them ideal for larger production runs where speed and accuracy matter most.

How to Choose the Right Machine

When it comes to choosing the right machine for your needs, there are several factors you should consider before making your decision. The first is what type of material you will be working with; different materials require different tools and techniques for optimal results. You should also consider what types of features you need from your machine; do you need high speeds or large part capacities? Finally, consider both your current needs and potential future requirements so you can choose a machine that will meet all your machining needs now and in the future.

CNC lathes come in many shapes and sizes to suit many different applications. Whether you need a basic single-axis model or an advanced combination turning center with multiple axes capabilities, there’s a machine out there that’s perfect for your needs. By considering all the important factors when selecting a machine—including material types, required features, and current needs vs future needs—you can always get the best possible results from your machining projects!

An Overview of CNC Lathe Machines and How to Use Them

CNC lathe machines are powerful tools designed to automate machining processes. They are essential in many industrial manufacturing operations, from automotive to aerospace. CNC lathes provide precision and accuracy that manual operations cannot match and can produce parts with a high degree of complexity. In this article, we will discuss the basics of using a CNC lathe machine and the benefits they offer for your project.

Operation Basics

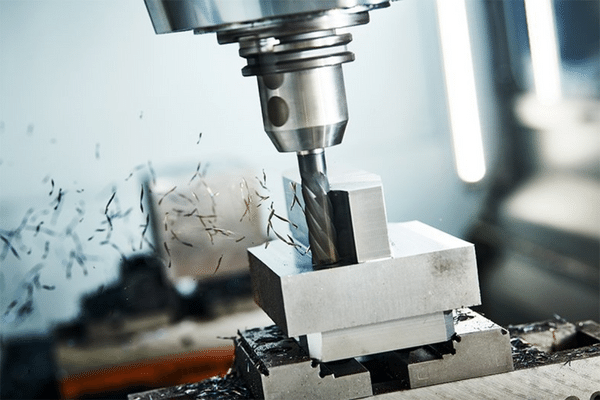

A CNC Lathe Machine is used for the automated machining of metal or plastic components by rotating them about their axis at high speeds while cutting tools cut away material from the parts being worked on. The basic operation involves mounting the part onto a spindle, setting up the tooling according to the design specifications, and then programming the machine with instructions as to how it should move and cut along with feeding in details such as speed and feed rate. Once programmed, the machine will repeat its instructions over and over again until all parts are completed.

Benefits of Using a CNC Lathe Machine

Using a CNC lathe machine offers numerous advantages over manual operation including increased productivity, better quality control, faster production times, improved safety standards, and more cost-effectiveness overall. With improved production times comes greater accuracy, leading to fewer mistakes in parts made and less scrap material created during production runs. This translates into lower costs for materials used in production which can also be beneficial when working within tight budget restraints. Additionally, it also helps reduce downtime due to errors or incorrect programming which can lead to delays in getting products out on time.

Applications for CNC Lathes

CNC lathes have a wide range of applications such as turning complex shapes (including tapers), drilling holes into specific depths or diameters, threading nuts or bolts onto products, cutting threads on bolts or screws (known as thread milling), creating angled surfaces (known as sloping or chamfering), deburring edges (removing sharp edges) and creating grooves along components for other operations such as welding or assembly. These machines are also used extensively in aerospace engineering where intricate shapes need to be produced accurately with minimal wastage of materials during production runs.

In conclusion, no matter what industry you’re in there are likely applications where using a CNC lathe machine could benefit you greatly. Whether you’re looking for greater accuracy and higher quality control over your manufacturing process or want faster production times with lower costs for materials – using one of these machines could be just what you need! It is important that you do thorough research before investing in one to get exactly what you need out of it – but once you understand how it works and its various capabilities it can be an incredibly useful tool that can help bring your projects up to new levels of precision!

How CNC Lathe Machines Are Used in Various Industries

CNC lathe machines are becoming increasingly popular among a variety of industries. These machines enable businesses to create intricate parts and components with higher precision, accuracy, and speed than ever before. In this blog post, we will explore the various industries that use CNC lathe machines and the advantages they offer.

Aerospace Industry

The aerospace industry is one of the most prominent users of CNC lathe machines. This is because these machines can produce complex parts and components from various materials with excellent accuracy and repeatability. For example, some aerospace parts require very precise tolerances due to their vital role in flight operations. A CNC lathe machine can produce these complex parts quickly and accurately.

Automotive Industry

The automotive industry is another major user of CNC lathe machines. The high precision offered by these machines allows for the production of parts such as pistons, cylinder heads, engine blocks, and other components that must meet exact specifications to ensure reliability and performance. Additionally, the speed at which a CNC lathe machine operates allows for increased efficiency on the factory floor.

Medical Industry

CNC lathe machines are also used in the medical industry to produce implants and prostheses more accurately than ever before. These devices must meet tight tolerances in order to ensure patient safety; therefore it is imperative that they are produced with maximum precision using materials such as titanium or stainless steel. The accuracy offered by a CNC lathe machine makes it an ideal tool for producing highly accurate medical implants and prostheses quickly and easily.

CNC lathe machines have become essential tools for many industries because they produce complex parts faster and more accurately than ever before. From aerospace components to medical implants, these versatile tools can be used to create high-precision parts for a wide range of applications quickly and efficiently. If you’re looking for an efficient way to produce intricate components, then a CNC lathe machine may be just what you need!

CNC Machining: Advantages and Disadvantages of Using a CNC Lathe Machine

CNC machining is a popular manufacturing method that uses computer-controlled lathes to cut metal and other materials into precise shapes. This method has been used by many industrial manufacturers for decades and is now becoming increasingly popular among smaller companies that want to be able to produce products with high levels of accuracy. This article will discuss the advantages and disadvantages of using a CNC lathe machine for your machining needs.

Advantages of CNC Machining

The primary advantage of using a CNC lathe machine is its accuracy. Because the machine is computer-programmed, it can produce parts with extremely precise dimensions and tolerances. This means that you won’t have to worry about human error or inconsistencies when producing parts. Additionally, since the machine operates at high speeds, it can turn out parts quickly and efficiently, helping you save time and money in the long run.

Another benefit of using a CNC lathe machine is its ability to work with complex shapes. Since these machines are designed to move along three axes (X, Y, Z), they can easily handle intricate designs without additional setup or programming changes. This makes them great for prototyping new products or creating custom pieces for specialized applications.

Disadvantages of CNC Machining

While there are many benefits to using a CNC lathe machine, there are also some potential drawbacks as well. The first issue is cost; because these machines are expensive to purchase and maintain, they may not be feasible for smaller businesses on tight budgets. Additionally, if you don’t have experience working with this type of machinery, you may need to hire an expert in order to get the most out of your investment. Finally, since these machines are programmed via computers, they require regular maintenance in order to ensure accuracy over time as components wear down or become outdated due to software updates or hardware changes.

While there are some potential drawbacks associated with using a CNC lathe machine for your machining needs, there are also many advantages that make it well worth the investment. From its ability to produce highly accurate parts quickly and efficiently to its capability for working with complex shapes without additional setup or programming changes needed, the benefits far outweigh any potential downsides when considering whether or not this type of equipment should be used in your machining operations. Ultimately, if you’re looking for an automated solution that offers precision and reliability at an affordable price, then investing in a CNC lathe machine could be just what you need!