Copper C360

If you’re working with Copper C360, ensure you have all the facts – ETCN’s guide has you covered.

Details of Copper C360

| Property | Value |

|---|---|

| Alternative Names | Free Machining Brass, C36000 |

| Density | 8.53 g/cm3 |

| Melting Point | 996 °C |

| Thermal Conductivity | 118 W/(m·K) |

| Electrical Conductivity | 27% IACS |

| Yield Strength | 275 MPa |

| Tensile Strength | 570 MPa |

| Elongation at Break | 40% |

| Modulus of Elasticity | 110 GPa |

| Poisson's Ratio | 0.34 |

| Hardness, Brinell | 80-150 |

| Hardness, Rockwell B | 45-70 |

| Post Treatments | Annealing, Quenching, Tempering |

| Common Applications | Plumbing, Electrical Fittings, Automotive Parts, Hardware |

Blogs related to CNC Machining Copper

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Copper C360: Frequently Asked Question

•Copper C360 is an alloy composed of copper and zinc with a copper content of up to 65%.

•It provides excellent thermal and electrical conductivity, as well as good machinability and corrosion resistance.

•It is commonly used in many applications such as electrical wiring, heat exchangers, industrial machinery parts and components, forging processes, and other special high-performance applications.

•Its excellent mechanical strength makes it ideal for use in heavy-duty applications, while its corrosion resistance ensures a longer component life span.

•Copper C360 is widely used in various industries, including automotive, electronics, plumbing, and HVAC, where its exceptional properties make it an ideal material for parts and components that require high precision, durability, and conductivity.

•It is commonly used in electrical connectors, valve bodies, gears, and fittings, as well as in plumbing fixtures such as faucets and showerheads.

•Its excellent machinability and good solderability also make it easy to work with, which is an added advantage in manufacturing.

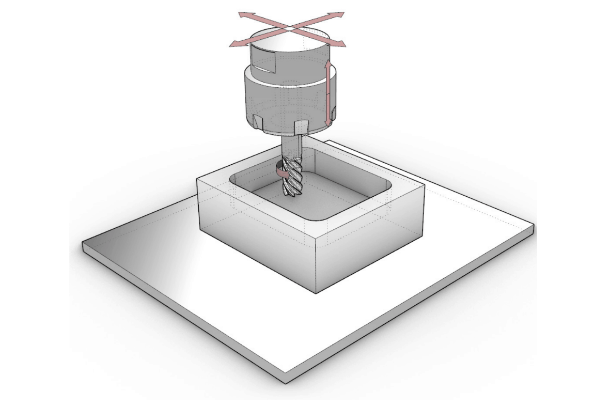

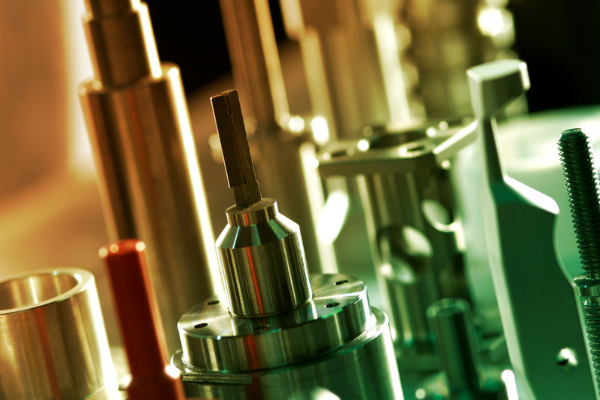

• To machine Copper C360 effectively, it is essential to use the right cutting tools, lubricants, and cooling fluids, as well as to follow proper machining parameters and techniques.

• For example, using carbide or high-speed steel tools with sharp edges and positive rake angles can minimize tool wear and chip formation, while using a water-soluble coolant can help reduce heat buildup and prevent oxidation.

• Additionally, optimizing machining parameters such as cutting speed, feed rate, and depth of cut can help improve productivity and reduce cycle time.

• Copper C360 is an environmentally friendly material that offers several sustainable benefits, such as its lead-free composition, which reduces the risk of toxicity and pollution.

• It is also a highly recyclable material, with a recycling rate of over 90%, which means that it can be reused and repurposed many times without degrading its properties.

• By using Copper C360 in manufacturing, companies can reduce their carbon footprint, minimize waste generation, and promote circular economy principles, which are essential for achieving long-term sustainability.

• Copper C360 is an alloy with up to 65% copper content that offers superior thermal and electrical conductivity, excellent machinability, and corrosion resistance – making it ideal for manufacturing.

• It has greater work hardening capabilities, improved formability, and higher tensile strength than other non-ferrous alloys.

• Its electrical conductivity allows for reliable connections, machinability enables intricate components, and corrosion resistance ensures a long component life span.

• Compared to brass or aluminum alloys, Copper C360 provides enhanced durability with its increased strength and cost-effectiveness when considering larger orders or longer production runs.

• Heat treating may be needed during forming due to its hardness, while welding requires specialized equipment because of its high melting temperature range.

• Copper C360 is a versatile material that offers many beneficial qualities in manufacturing.