ETCN provides tapping service from china. We can help you to find the manufacturers and suppliers of different tapping tooling. If you need it, please timely contact us.

Home » Tapping with a Drill

What Is Tapping and How Does It Work?

- Tapping is a machining process in which an internal thread is formed in a workpiece. The process is done by cutting a spiral groove on the surface of the workpiece and then cutting an external thread on the surface of the groove.

- Tapping can be performed by hand, but it’s more common for it to be done with a machine tool. Machines used for tapping include screw machines, CNC lathes, and CNC milling machines.

- Tapping is cutting internal threads in the workpiece hole with a tap.

- The threads machined by tapping are mostly triangular threads, which are the connecting structures between parts. The threads commonly tapped are.

- Metric threads with a tooth angle of 60° are also common threads.

- Imperial threads with a tooth angle of 55°.Inch pipe threads and tapered pipe threads for pipe connections.

Basic dimensions of the common thread

(1) Thread diameter: d = D (the basic size of the thread diameter is the same as the nominal diameter)

(2) Middle diameter: d2 = D2 = d – 0.6495P

(3) Thread height: H = O.5413P

(4) Small thread diameter: d1 = D1 = d-1.0825P

drill press tapping guide

Thread Tapping Process

Tapping is a common element of hole machining on CNC milling machines and CNC machining centers. The selected tap is first mounted on a special tapping tool holder, preferably a floating tool holder with tension and compression characteristics. The tapping steps are as follows.

♦Step 1: X and Y positioning.

♦Step 2: Select spindle speed and direction of rotation.

♦Step 3: Rapid movement to point R

♦Step 4: Feed movement to the specified depth.

♦Step 5: Spindle stops.

♦Step 6: Spindle reverses rotation.

♦Step 7: Return of the feed movement.

♦Step 8: Spindle stop.

♦Step 9: Rapid return to the initial position.

♦Step 10: Restart normal spindle rotation.

Tapping Cycle G84, G74 Format

(1) Command format.

Tapping left-hand thread: G74 X~Y~Z~R~P~F~.

Tapping right-hand thread: G84 X~Y~Z~R~P~F~.

(2) Hole machining action.

The G 74 cycle is used for machining left-hand threads. When this cycle is executed, the spindle reverses and moves quickly to the R point after quick positioning in the XY plane.

The G84 action is similar to the G74, except that the G84 is used for right-hand threads. To perform this cycle, the spindle is turned forward, positioned quickly in the G17 plane, and then moved quickly to point R. After tapping the threads and reaching the bottom of the hole, the spindle is reversed and returned to point R. The spindle resumes forward rotation and completes the tapping action.

The feed rate during tapping is specified according to the different feed modes. In the G94 mode, the feed rate = lead length x speed. In G95 mode, feed rate = lead. During G74 and G84 tapping, the feed multiplier and feed hold are ignored.

Hole machining programming

Machining procedures are prepared as follows.

O6501

(T01 – 18mm diameter spot drill)

g21 g17 g40 g80 t01

T01 M06

g90 g54 g00 x33 y30 s350 m03 t02

g43 z50.0 h01 m08

g99 g82 r5.0 z-6.5 p100 f35

M98 P6502

g80 z50.0 m09

g49 g28 z10.0 m05

M01

need help?

Get your tapping solution for free

1/4-20 tap size

The 1/4-20 tap size is considered an American Standard Taper (AST) thread and corresponds to Unified Screw Threads (UNC). The Unified Screw Thread Standardization Committee (USSC) developed the UNC system in 1916 to provide uniformity among all threads used in the United States. With this new standard, manufacturing companies could manufacture parts that would fit together without modifying them after they were built. The system was also designed to be compatible with the existing British Standard Whitworth (BSW) and German Standard threads, making it possible for manufacturers to continue using the parts they had already produced.

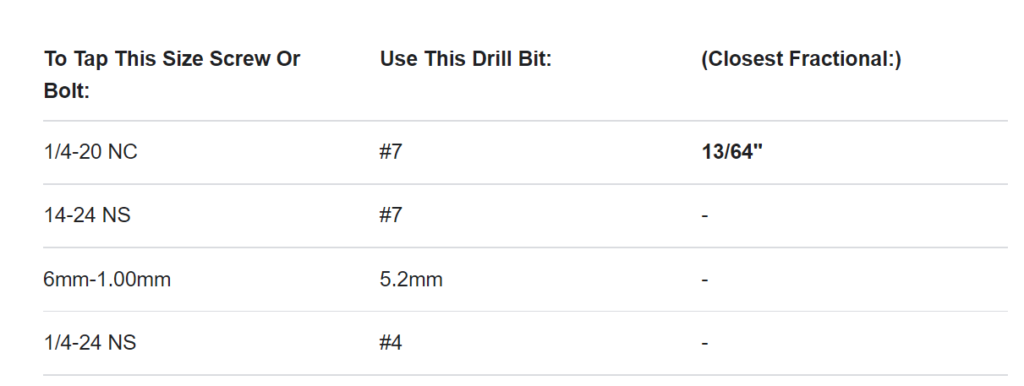

what size drill bit do you use for 1/4 20 tap

The correct size drill bit for tapping a 1/4″ 20 hole is a #18 drill bit.

1/4″ 20 tap drill bit chart:

Tapping Drill Size Inches Metric

3/16″ 7.9mm

1/4″ 6.4mm

5/16″ 8.0mm

3/8″ 10.0mm

7/16″ 11.1mm

Drill Bit Size for M8 Tap

The M8 tap is metric and requires a metric drill bit. The tap and drill bit have a diameter of 0.80mm, so there is no need to worry about getting the size right. The M8 tap has a thread pitch of 1.25mm, and the drill bit must match this pitch to ensure that poor-quality threads do not damage the threads. A standard thread pitch gauge can be used to measure the pitch of the threads on your drill bit and check they match those on your M8 tap.

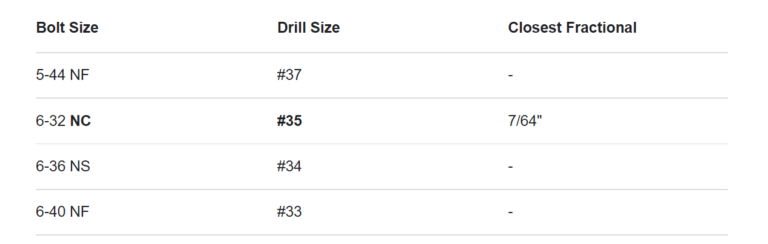

6/32 tap drill size

The 6/32 tap drill size is a metric used to make holes with a 6 mm diameter. The number “6” refers to the nominal diameter of the drill bit. The “/32” refers to the length of the drill bit, which is 32 thousandths of an inch or 0.03125 inches long. The 6/32 tap drill size has a plus or minus 1/64 inch tolerance.

Tap Drill Size Chart

Tap Drill Size Diameter Tolerance Holes per inch 2-56 .0938 +/- .0005 25 4-40 .1083 +/- .0005 24 6-48 .1250 +/- .0007 22 8-36 .1406 +/- .0008 20 10-24 .1562 +/- .0010 17 1/4-20 .1938 +/- .0012 15 5/16-18 .2188 +/- .0014 13 3/8-16 .2656 +/- .0017 11 7/16-14 .3125 +/- .0019 9 1/2-13 3/4-.3438+/-.0022 8 9/16-.3750+/-.0026

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.