Copper C110

Need to learn more about Copper C110? Look no further than ETCN for comprehensive information on this versatile metal and its properties.

Details of Copper C110

| Property | Value |

|---|---|

| Alternative Names | C11000, Electrolytic Tough Pitch Copper |

| Density | 8.94 g/cm3 |

| Melting Point | 1083 °C |

| Thermal Conductivity | 385 W/mK |

| Electrical Conductivity | 100% IACS |

| Yield Strength | 110 MPa |

| Tensile Strength | 260 MPa |

| Elongation | 40% |

| Hardness | 60 HRB |

| Post Treatments | Annealing, cold working, hot working |

| Common Applications | Electrical applications, transmission lines, bus bars, plumbing, radiators |

Blogs related to CNC Machining Copper

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Copper C110: Frequently Asked Question

• Copper C110 is a strong and conductive alloy used for applications in many industries, from electronics to aviation.

• It is renowned for its ductility, which allows it to form into intricate shapes, and its corrosion resistance and high strength-to-weight ratio.

• This alloy can be used for parts like wiring, turbine blades, and medical instruments due to its properties such as excellent conductivity and high melting point.

• Limitations should be taken into consideration such as oxidation issues when exposed to air or reactions with certain chemicals.

• Safety protocols must be followed when using Copper C110 including wearing gloves during setup and storing it away from heat sources or direct sunlight.

•Copper C110 is composed of 99.9% copper and .1% phosphorus, making it a versatile alloy with excellent electrical conductivity and solderability.

•It also has a high ductility as well as a high strength-to-weight ratio, making it ideal for projects that require superior durability and performance in extreme temperatures or environments.

•Copper C110 is corrosion-resistant and has a melting point of 1,083 degrees Celsius. These specs make it suitable for use in industries such as electronics, aviation, plumbing, medical equipment, and more.

• To anneal and harden Copper C110, preheat the furnace to 1000 degrees Celsius (1832 Fahrenheit) and slowly add Copper C110 while maintaining the same temperature.

•Allow it to cool down naturally in order to increase its malleability; this process is known as annealing.

•To harden Copper C110, preheat the furnace again and maintain 890 degrees Celsius (1634 Fahrenheit). Quickly dip the heated copper into a cold water or oil bath for rapid cooling; this process is known as quenching.

•Handle Copper C110 carefully throughout the entire process, wear safety glasses when working with hot metals, and use appropriate tools instead of bare hands wherever possible.

•Record time spent in each temperature zone as well as the rate of cooling for reference purposes later on.

• Copper C110 boasts superior electrical and thermal conductivity, corrosion resistance, ductility, and malleability. It is one of the best economical yet long-lasting material solutions available in the market.

• It’s ideal for applications such as wiring, forging, and fabrication due to its high level of malleability.

• Copper C110 is a highly versatile material suitable for a wide range of products, from electrical wiring to industrial machinery components.

• Its strong thermal conductivity makes it suitable for industrial heat exchangers, while its corrosion-resistant properties help reduce maintenance costs and unexpected downtime.

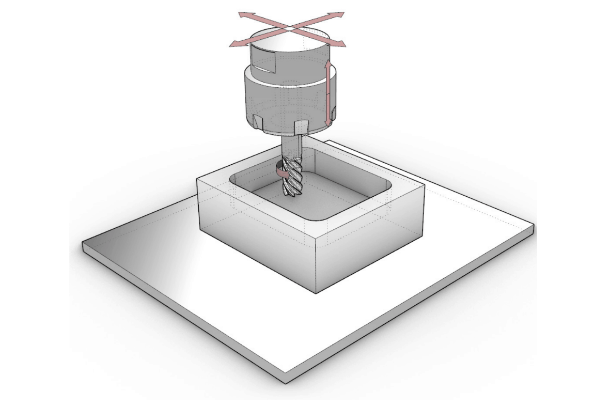

•Copper C110 is commonly used in a variety of different applications due to its superior properties. It is often found in electrical wiring, industrial machinery components, heat exchangers, and forging processes.

•Its superior electrical and thermal conductivity makes it an ideal material for wiring and other electrical applications.

•It also performs well as a heat exchanger material due to its excellent thermal conductivity and corrosion-resistant properties.

•In addition, its malleability makes it perfect for forging processes where intricate parts are created from the alloy.

•Finally, it provides exceptional strength and durability when used to construct industrial machinery components.

•Wholesalers can benefit from partnering with a manufacturer of Copper C110 by being able to offer high-quality, reliable, and efficient copper alloy to their customers.

•As a manufacturer, we can ensure the consistency and quality of our Copper C110 products, ensuring our wholesalers’ reliability and reputation in the market.

•Our experience in the industry also allows us to offer dedicated support and expertise in selecting the right Copper C110 products for various applications, ensuring complete customer satisfaction.