TOP Sheet Metal Cutting supplier from china

ETCN supplies sheet metal cutting service, as well as promotional products for your business.

Sheet Metal Cutting

There are a variety of materials that can be used in sheet metal cutting, depending on the application. Some of the most common materials include stainless steel, aluminum, and brass. Each of these materials has their own unique properties that make them ideal for different applications.

The Different Types of Sheet Metal Cutting

There are many different ways to cut sheet metal, and each has its own advantages and disadvantages. The most common methods are shearing, sawing, and laser cutting.

Shearing is a cutting process that uses sharp blades to cut the metal into desired shapes. It is a fast and efficient method, but it can be difficult to achieve precise cuts.

Sawing is another common method of cutting sheet metal. It uses a rotating blade to cut through the metal. Sawing is more accurate than shearing, but it is also slower.

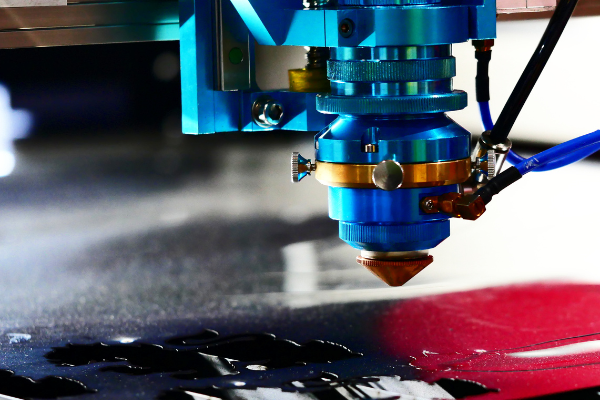

Laser cutting is a newer technology that uses a focused beam of light to cut through the metal. Laser cutting is very precise, but it is also very expensive.

What Materials are Used in Sheet Metal Cutting?

There are a variety of materials that can be used in sheet metal cutting, including stainless steel, aluminum, and even titanium. each material has its own benefits and drawbacks, so it’s important to choose the right one for your project. Here’s a quick overview of some of the most popular materials used in sheet metal cutting:

-Stainless steel is one of the most popular choices for sheet metal cutting. It’s strong and durable, making it ideal for projects that require a high level of precision. However, stainless steel can be difficult to work with and is often more expensive than other options.

-Aluminum is another popular choice for sheet metal cutting. It’s lightweight and easy to work with, making it a good option for projects that don’t require a lot of precision. However, aluminum can be easily damaged and is not as strong as stainless steel.

-Titanium is a strong and lightweight option for sheet metal cutting. It’s also corrosion resistant, making it a good choice for projects that will be exposed to the elements. However, titanium can be difficult to work with and is often more expensive than other options.

Alternatives to Sheet Metal Cutting

If you’re looking for alternatives to sheet metal cutting, there are a few options available. You can use a plasma cutter, waterjet cutter, or laser cutter. Each of these has its own advantages and disadvantages, so you’ll need to decide which is best for your project.

Plasma cutters are fast and can cut through thick materials. However, they can be difficult to control and can create a lot of heat and noise.

Waterjet cutters are very precise and can cut through almost any material. However, they are very expensive and require a lot of setup time.

Laser cutters are very precise and can cut through thin materials. However, they are very expensive and require a lot of setup time.

Sheet Metal Cutting FAQs

Frequently Asked Questions.

What is the best tool to use to cut sheet metal?

If you’re working with sheet metal, then you know that the right tool makes all the difference. So, what is the best tool to use to cut sheet metal?

There are a few different options available, but the two most popular choices are power shears and plasma cutters. Let’s take a closer look at each one to see which is the best option for your project.

Power Shears:

Power shears are a great option for cutting sheet metal, especially if you need to make clean, straight cuts. They’re also relatively inexpensive and easy to find. However, they can be a bit difficult to control, so it’s important to have some experience before using them.

Plasma Cutters:

Plasma cutters are another popular choice for cutting sheet metal. They’re more expensive than power shears, but they’re much easier to use and offer more precision. If you’re new to working with sheet metal, then a plasma cutter is probably the best option for you.

What is sheet metal cutting process?

If you’re new to the world of sheet metal fabrication, you might be wondering what the sheet metal cutting process is all about. In simple terms, it’s the process of using a variety of tools to cut sheet metal into the desired shape or size.

There are a few different methods that can be used to cut sheet metal, including:

– Waterjet cutting: This method uses a high-pressure stream of water to cut through the metal.

– Laser cutting: A laser is used to heat up and melt the metal, making it easy to cut through.

– Plasma cutting: Plasma cutting uses an electric arc to heat and melt the metal.

– Machining: Machining is a more traditional method that involves using tools like saws and drill bits to cut through the metal.

How do you cut a thin sheet of metal at home?

With the right tools, cutting a thin sheet of metal at home is a relatively easy task. Here are the steps you’ll need to take:

1. gather your materials. You will need a sharp metal cutting blade, a straight edge, and clamps.

2. mark your cut line on the metal sheet. Use a pencil or other sharp object to score a line on the surface of the metal. This will be your guide for making the cut.

3. set up your cutting blade. Make sure the blade is securely attached to your cutting tool and that it is sharp. A dull blade will make it more difficult to cut through the metal.

4. position the straight edge along your cut line and clamp it in place. This will help you keep a steady hand while cutting.

5. begin cutting along the line. Apply even pressure as you move the blade through the metal. If the blade starts to drift, stop and realign it with the line before continuing.

How do you cut metal by hand?

One of the most common ways to cut metal by hand is with a hacksaw. A hacksaw is a hand saw that has a thin, sharp blade that is specifically designed for cutting metal. To use a hacksaw, you simply insert the blade into the metal you want to cut and then saw back and forth until the metal is cut through.

Another option for cutting metal by hand is with a file. A file is a tool that has a abrasive surface that can be used to grind down or smooth out the edges of metal. To use a file to cut metal, you would simply place the file against the metal and then move it back and forth until the metal is cut through.

Finally, another option for cutting metal by hand is with an angle grinder. An angle grinder is a handheld power tool that has a rotating disk that is covered in abrasive material. To use an angle grinder to cut metal, you would hold the tool against the metal and then move it in a circular motion until the metal is cut through.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.