CNC machining polycarbonate

ETCN is a professional China polycarbonate parts manufacturer & supplier; many kinds of polycarbonate molds or tooling products are customized.

Home » CNC machining polycarbonate

polycarbonate CNC

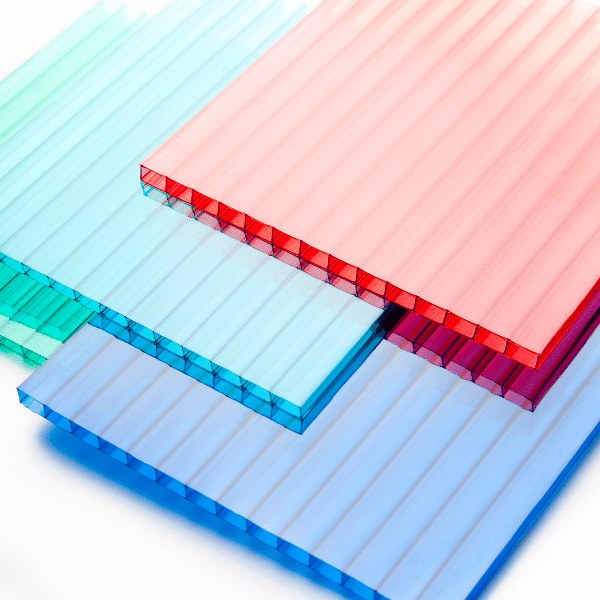

Polycarbonate (PC) is a thermoplastic, transparent, tough material used for various applications. It is strong, durable, and stiff plastic. It is a good choice for making parts with important heat resistance, such as UV lamps and lights. Polycarbonate can be injection molded or extruded into various shapes such as sheets, tubes, rods, and profiles. Polycarbonate is available in many colors, including yellow, green, orange, red, blue, and black.

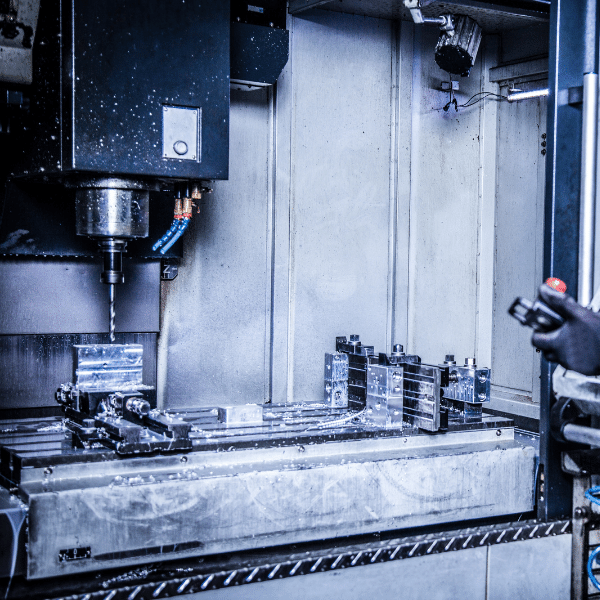

Polycarbonate CNC Machining

The machining process of polycarbonate requires the use of high-quality tools with excellent tool life. The machinability of polycarbonate depends on its cross-section thickness, material grade, and chemical composition. Due to its high hardness and toughness characteristics, it’s difficult to cut by conventional methods like milling or turning. But nowadays, there are several techniques available to machine polycarbonate materials like:

● High-speed milling or drilling with carbide tools

● Deep hole drilling with carbide drills

● Surface grinding with diamond abrasives

Benefits of Polycarbonate Materials

Polycarbonate materials are commonly used in construction, automotive, and consumer goods industries. Polycarbonate is a strong and lightweight material that offers many benefits over other materials.

Benefits of Polycarbonate Materials

♦ 1. Lightweight

♦ 2. Durable

♦ 3. Impact Resistant

♦ 4. Weather Resistant

♦ 5. Availability

Designing for Polycarbonate Machining

Polycarbonate is a transparent thermoplastic with high impact strength, rigidity, and chemical resistance. It’s a versatile material used in various applications, including automotive glazing, lighting, electronics, and eyeglasses.

Polycarbonate machining is a complicated process that involves multiple steps and equipment to achieve the desired result. It’s important to consider these factors when designing your part:

♦ 1. The shape and size of the part

♦ 2. The material grade and thickness

♦ 3. The required tolerances (tolerance stack-up)

♦ 4. The type of tooling (cutting tools) required for each operation

Common Applications for Polycarbonate Machining

Polycarbonate is a tough, high-impact thermoplastic material that can be machined to a high degree of precision. It can be used for various applications, from automotive accessories to safety equipment.

Common Applications for Polycarbonate Machining

Polycarbonate is ideal for applications where impact resistance and durability are essential. It can be used in a variety of industries, including:

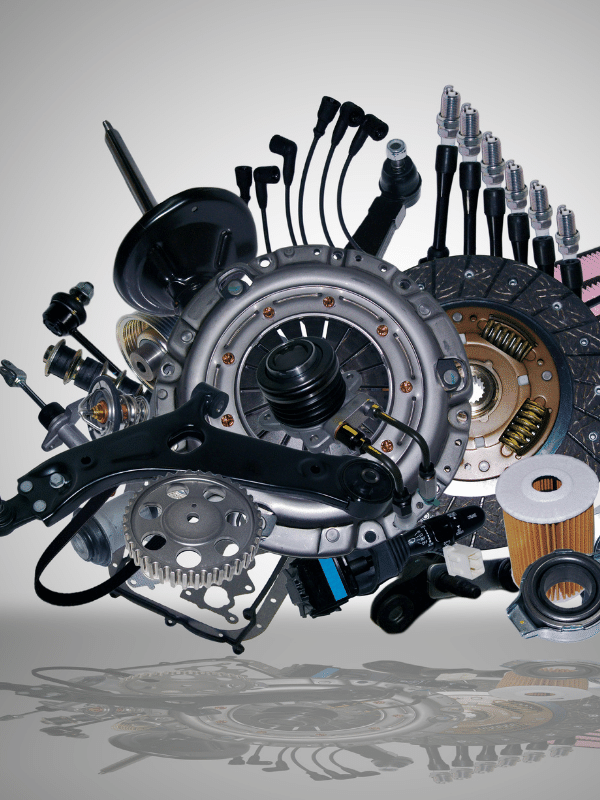

♦ Automotive manufacturing: Polycarbonate can be used to replace glass in windows, headlights, tail lights, and more. It’s also ideal for use as exterior trim panels or interior accessories. Polycarbonate can also be shaped into auto body parts like bumpers and headlamp covers.

♦ Aerospace: In addition to windows and windshields, polycarbonate is used in aircraft cockpit components like instrument panels and nose cones. It’s also used in military applications such as bulletproof shields and vehicle armor plating.

♦ Electronics: Polycarbonates are often used as electronic parts because they’re lightweight and easy to machine without compromising strength or durability. They can be machined into buttons, switches, and other components that require precise dimensions while still being able to withstand the heat generated by electronic devices such as computers or televisions

Polycarbonate Cutting Methods

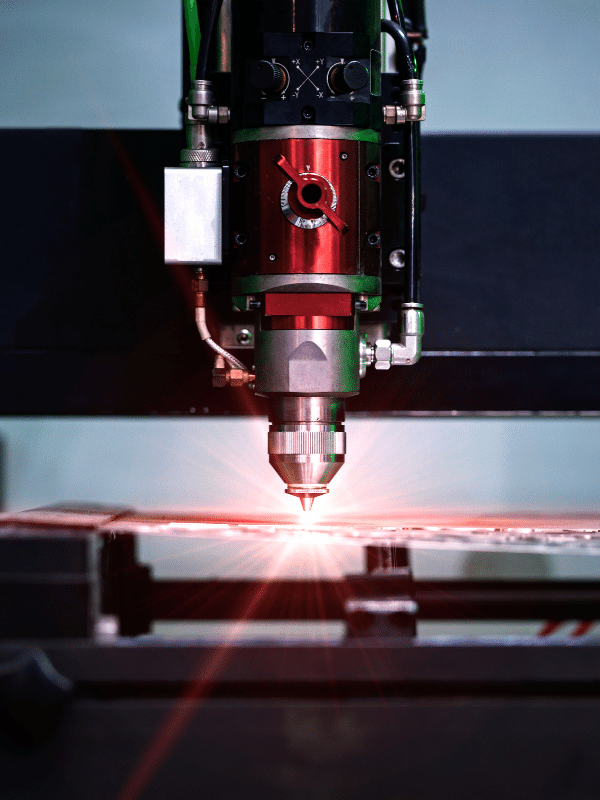

♦ 1. Laser Cutting

Laser cutting is one of the most common methods of cutting polycarbonate sheets. This technology produces clean cuts without any residue or burrs, which can be challenging with other methods. Depending on the type of laser used and the thickness of your material, you may need to use protective eyewear while operating the machine. The laser can also burn through thin materials or leave them damaged if not properly controlled by an operator.

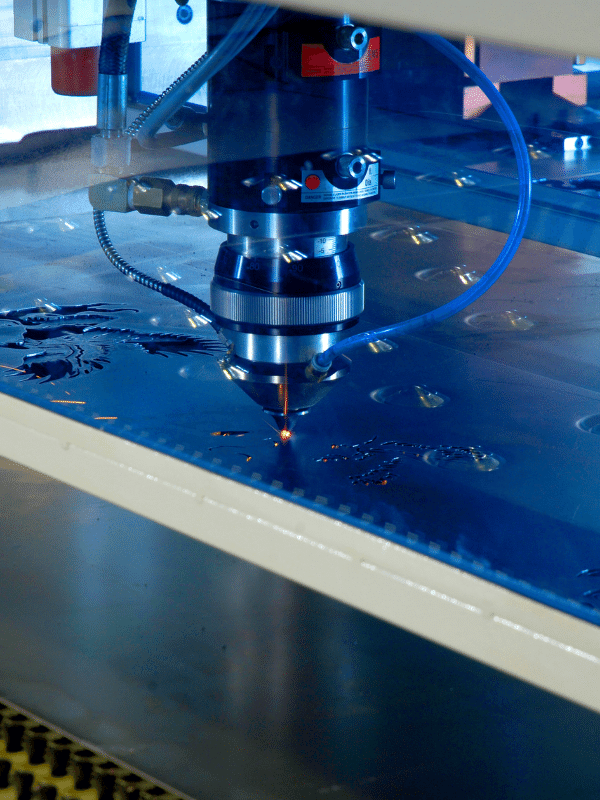

♦ 2. Waterjet Cutting

Waterjet cutting uses high-pressure water with abrasives to cut through polycarbonate sheets, similar to sandblasting. This process involves using water at pressures of up to 60,000 psi (414 bar) and temperatures as low as -10°F (-23°C). Waterjet cutting machines use computer-controlled motion systems that allow for high accuracy and repeatability when creating parts from large sheets of material.

custom polycarbonate parts

Polycarbonates are the most versatile plastic materials available today. They can be molded into various shapes and sizes and are strong and lightweight. In addition to their high impact strength, polycarbonates have superior abrasion, chemical, and temperature resistance when compared to other engineering plastics. Polycarbonates can be used in applications that require high-impact strength, such as automotive components, sports equipment, safety glasses, and helmets.

Custom Polycarbonate Parts are available in all shapes, sizes, and colors to fit your needs. We can deliver fast turnaround times and a high-quality product at an affordable price. We provide this service locally in the Dallas/Fort Worth area and nationwide.

♦ It can be made in any color

♦ Can be made in any size (minimum order quantity may apply)

♦ Can be made with custom logos or graphics printed on them.

milling polycarbonate

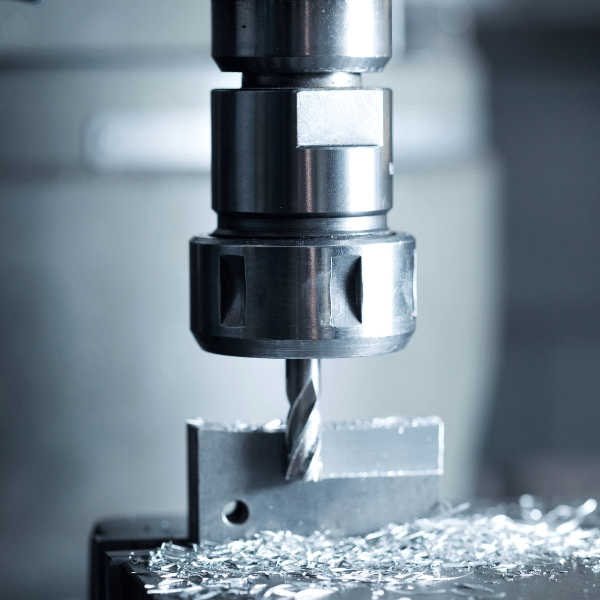

♦ Milling polycarbonate is a process that creates a flat surface on polycarbonate. Milling is necessary for many applications, including glass and plastic lenses. The process uses a milling machine to cut through the plastic material, creating an even surface.

♦ Milling polycarbonate is typically done with carbide tool bits with high hardness ratings, allowing them to withstand constant contact with other surfaces without being damaged or dulled by them. Carbide bits are also often used because they are more expensive than other types of bits and last longer than other materials used for milling machines, such as steel or titanium carbide products.

machinability of polycarbonate

♦ The machinability of Polycarbonate is very good. It has a good surface finish and can be machined with conventional tooling. However, it should not be over-machined as this will distort the material.

♦ Polycarbonate can be cut with carbide tools at speeds ranging from 250 to 500 m/min (1000 to 2000 ft/min). Depending on the material thickness, the cutting temperature should be between 300 and 400°F (150 to 200°C).

♦ Polycarbonate is relatively easy to machine compared with other engineering plastics because it has a low coefficient of friction and good thermal conductivity, which helps dissipate heat generated by cutting operations.

Common Polycarbonate CNC Machined Parts

♦ 1. Polycarbonate sheet

♦ 2. Acrylic sheet

♦ 3. PMMA sheet

♦ 4. Lexan sheet

♦ 5. UV sheet adhesives for polycarbonate, acrylic, and PMMA

♦ 6. The acrylic film, adhesive vinyl film for polycarbonate, and acrylic

♦ 7. PMMA film for polycarbonate, acrylic, and PMMA

♦ 8. PVD coated glass for polycarbonate and acrylic

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.