CNC Machining ABS

ETCN specializes in designing and engineering precision injection molds and machining parts from ABS and other materials using Computer Numerical Control (CNC) technology.

Home » CNC Machining ABS

What is Machining Abs Plastic?

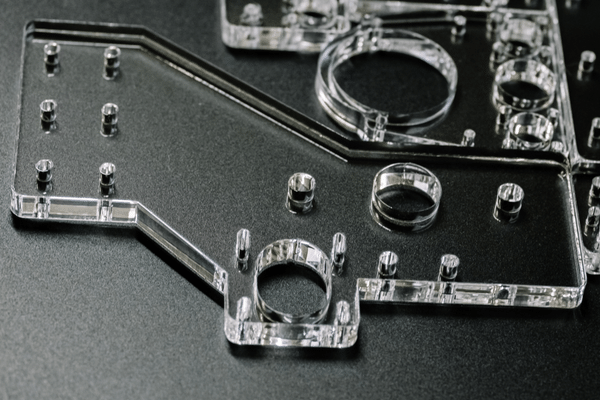

ABS Plastic is a tough material that has a high impact strength. It is commonly used in constructing 3D printers and CNC machines because it requires high-precision machining.

ABS plastic is a durable plastic that can be machined with a CNC milling machine. The process of machining ABS is similar to other plastics, such as polycarbonate or polyurethane, but there are some differences.

Machining ABS has several advantages over other materials:

♦ It is available in large sheets up to 48 inches by 96 inches (122 cm x 243 cm).

♦ It can be cut into large pieces with relatively little waste compared to smaller pieces.

♦ It can be machined at room temperature, eliminating the need for special fixtures or cooling equipment.

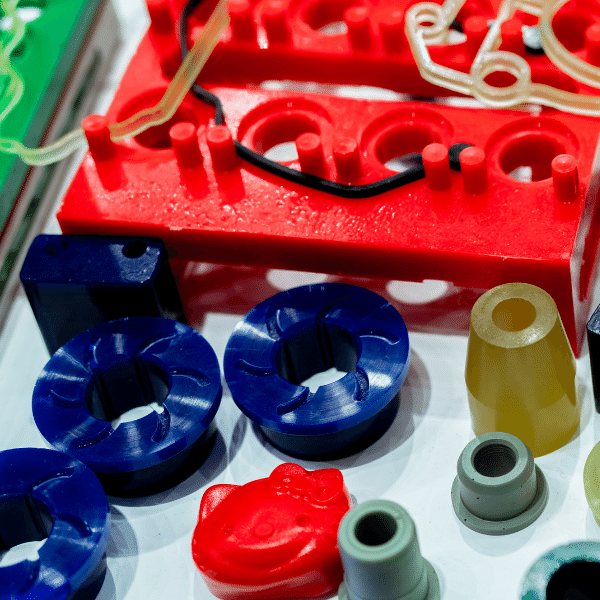

CNC Machined ABS Parts

CNC machined ABS parts are a great choice for manufacturers who want to produce a more durable and impact-resistant product. ABS is one of the most commonly used materials in the manufacturing industry and is also one of the most versatile. This makes it an ideal material for many products, including automotive, medical, and even toys.

ABS is a strong polymer that can be molded into any shape, which makes it the perfect material for creating complex shapes and designs. It is also lightweight and durable, making it an ideal choice for many applications.

We can manufacture any parts made of ABS material with our CNC machining center. We can also do large volume production for you. We can handle all your needs, whether you need a prototype or a small production run. Our services include:

♦ ABS plastic injection molding

♦ ABS plastic extrusion

♦ ABS plastic stamping

♦ ABS plastic tooling (tool making)

Advantages of CNC Machined ABS

The advantages of ABS precision machining are as follows:

♦ 1. Precision Machining is fast, easy, and cost-effective.

♦ 2. It improves the quality of your product in terms of accuracy, surface finish, and dimensional tolerance.

♦ 3. It reduces the time to market your new product or model by allowing you to manufacture prototypes quickly and cheaply.

♦ 4. It helps you create accurate prototypes to be used directly in testing without further modification or alteration.

♦ 5. It allows you to create models that can be used for showroom displays or exhibitions without having to invest in expensive tooling equipment or molds which could be complex and difficult to use effectively.

Applications of ABS Precision Machining

ABS Precision Machining is a process of machining plastic, rigid and soft metal components using high speed and high precision. It is more accurate, faster, and economical than conventional methods.

The main applications are:

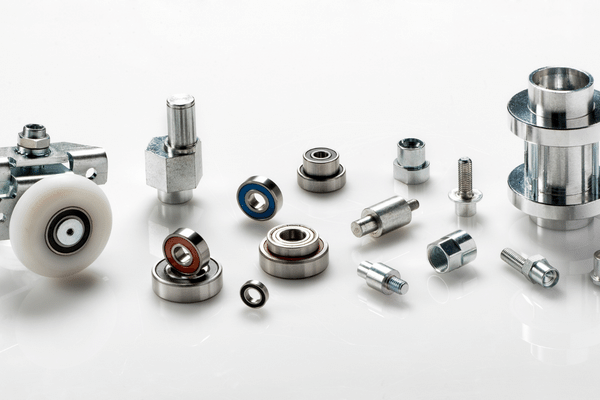

♦ Automotive parts

♦ Medical instruments

♦ Electronics components

♦ Injection molding tools

Features Of Our ABS Machining Service Plastic Machined Parts

We provide high-quality ABS machining service at a competitive price. We have a professional team and our factory. We can provide you with high-quality ABS machined parts at a competitive price. Our products are widely used in medical equipment, instruments, accessories, toys, and other industries. If you have any questions about our ABS machining service plastic machined parts, please tell us freely!

♦ 1 Fast delivery time

♦ 2 Excellent quality control system

♦ 3 One-stop solutions for customized orders

♦ 4 Strictly QC inspection before shipment

Frequently Asked Questions

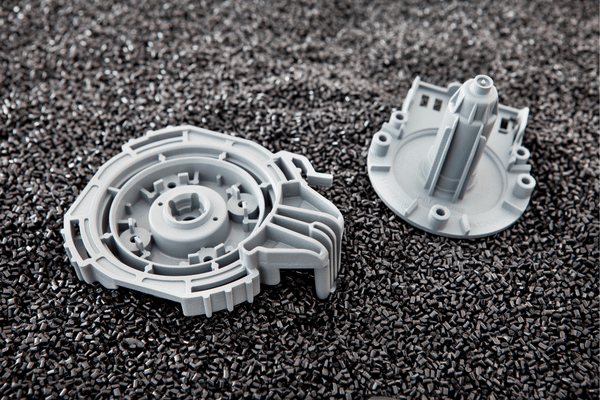

Injection moulding is a manufacturing process for producing parts by injecting material into a mould. It is one of the most commonly used processes in industry and also known as “injection molding”. The material to be molded is fed into a heated barrel, mixed with a catalyst if required, and then forced into a mould cavity where it cools and solidifies. The shot cycle begins when the barrel opens, and ends when the mould closes on the newly formed part.

Pre Injection Molding (PIM) is a process that has been used in the injection molding industry for about 30 years. PIM uses a high quality plastic (usually ABS or PC) to create the mold and then injects molten plastic into the mold. The result is a finished part with no tooling marks or parting lines, which are common characteristics of regular injection molded parts.

The main advantage of PIM over conventional injection molding is that it allows for greater design freedom and eliminates tooling costs associated with conventional methods. PIM also reduces cycle time because there are fewer pieces to assemble during production.

There are many benefits of CNC machined ABS. First, it is the most common 3D printing material. It is ideal for both prototyping and production. It has excellent mechanical properties, such as a strength of up to 70 MPa, a toughness of up to 25 MPa, and a modulus of elasticity of up to 2 GPa. Second, it has a good surface finish due to its excellent thermal stability. Third, it can be easily processed by milling or turning machines. Fourth, it has a low coefficient of friction and high wear resistance. Fifth, it does not shrink during cooling and does not warp during heating. Sixth, it has excellent chemical resistance and can withstand temperatures up to 120°C without any problems.

First of all, the price of engineering plastics is relatively low, especially when compared with metal materials. Therefore, customers can save a lot of money on materials.

Second, because the injection molding process is relatively simple, the cost of making a mold is also not high,In addition to the cost of raw materials and some auxiliary equipment costs.

Thirdly, because it has good mechanical properties and excellent performance, it can be widely used in many industries such as automobile manufacturing, electronic products manufacturing and so on.

1.Keep the temperature of the working area and the product to be machined within a certain range. If it is too high, it may cause deformation of the workpiece; if it is too low, it will affect the polishing effect and accuracy of machining.

2.In order to avoid damage to the product during transportation or storage, be sure to clean up after use and store them in a dry place with good ventilation.

3.In order to avoid dust accumulation in the molding cavity during molding, it is best to blow compressed air into the molding cavity before starting production.

4.It is not recommended to use oil-based lubricants for CNC machining ABS plastic parts because they may cause oxidation on their surface and affect appearance quality and friction performance of products made from ABS plastic parts.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.