Progressive Die Stamping

Progressive Stamping Die Manufacturers

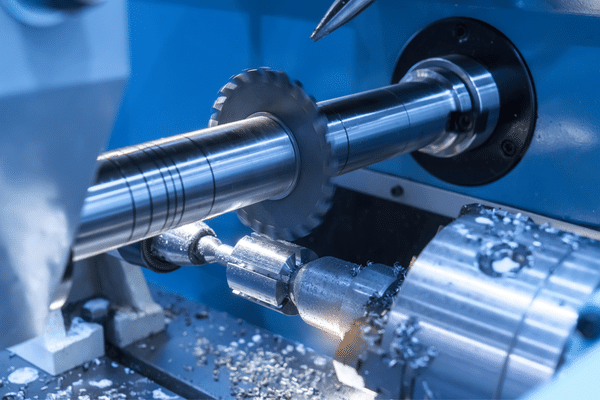

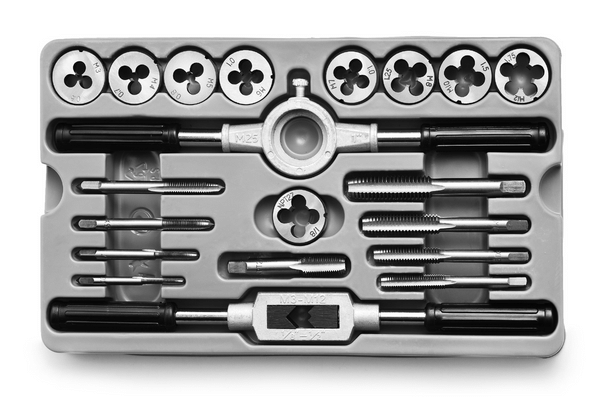

ETCN provides different tools and processes for manufacturing a variety of petroleum equipment components. These include stamping, CNC turning, thread processing, and laser welding, each performed with a powerful progressive die press.

Benefits of Progressive Die Stamping

There are a number of benefits to progressive die stamping, including:

1. Increased accuracy and consistency – Progressive die stamping produces more accurate and consistent products than traditional die stamping methods. This is because the dies are precisely positioned on the product as they are stamped, resulting in a more even finish.

2. Faster production times – Progressive die stamping can speed up production times by eliminating the need for multiple steps of die cutting and then applying the stamping dies. This means that products can be stamped quickly and easily, without having to wait for each step to be completed.

3. Lower manufacturing costs – Progressive die stamping can save businesses money on their manufacturing costs due to the increased accuracy and consistency of products. This is because there is less need for replacement parts or reworking of products due to incorrect stamping patterns.

4. Reduced waste – Progressive die stamping can help reduce waste by ensuring that every piece of product is stamped with a unique pattern. This eliminates the need for excess stock or copies of same-looking products, which can lead to unnecessary waste.

What are the method of stamping?

There are many methods of stamping, but the most common are:

-Dry Stamping: This method is best for detailed images or text. The ink is applied to the stamp directly and then pressed onto the paper. This method is great for intricate designs or for projects that require precise lines.

-Wet Stamping: This method is ideal for larger images or text. The ink is first applied to the paper and then the stamp is pressed onto the ink. This method is perfect for projects that require bold lines or color.

-Embossing: This method uses a special tool to create a raised image on the paper. It can be used to create textured effects or to add dimension to a design.

-Debossing: This method uses a special tool to create a recessed image on the paper. It can be used to create textured effects or to add dimension to a design.

Progressive Die Stamping : The Ultimate Guide to Faqs

Frequently Asked Questions.

What is Progressive Die Stamping?

Progressive die stamping is a process that is used to create complex parts from sheet metal. The process starts with a sheet of metal that is fed into a press. The press then stamps the metal to create the desired shape. The process is repeated until the desired shape is achieved.

Progressive die stamping offers many benefits over traditional stamping methods. Perhaps the most significant benefit is that progressive die stamping can create parts with much more intricate designs. Additionally, progressive die stamping generally requires less setup time than traditional stamping methods, and it can produce parts with closer tolerances.

The Different Types of Progressive Die Stamping

There are three different types of progressive die stamping: single-stage stamping, two-stage stamping, and draw stamping. Single-stage stamping is the most basic type of progressive die stamping, and in this process, the metal sheet is only stamped once. Two-stage stamping is a more complex process, in which the metal sheet is stamped twice. Draw stamping is the most complex type of progressive die stamping, and in this process, the metal sheet is first stamped, then drawn through a die.

Pros and Cons of Progressive Die Stamping

Progressive die stamping is a popular manufacturing process that offers many benefits. However, there are also some potential drawbacks to consider. Here are some pros and cons of progressive die stamping to help you decide if it’s the right manufacturing process for your project:

Pros:

– Higher production rates than other stamping methods

– Reduced material waste

– Increased accuracy and repeatability

– Can be used to create complex parts

Cons:

– Requires high initial investment in equipment and tooling

– Longer lead times than other methods

What Materials can be used for Progressive Die Stamping?

There are a variety of materials that can be used for progressive die stamping, including but not limited to: metals (steel, aluminum, brass), plastics (acrylic, polycarbonate), and composites (fiberglass, carbon fiber). What material is best for your application will depend on a number of factors, such as the required strength/durability of the part, the desired aesthetic finish, and the production volume.

Metal splashing during die casting can cause problems with the finished product. The pieces of metal that splash out can deform the die, creating inconsistencies in the shape of the object. This can lead to defects in the object, as well as injuries to workers involved in the process. Metal splashing also poses a danger to bystanders, as flying pieces of metal could injure them.

To prevent metal splashing during die casting, manufacturers should take precautions to keep the die clean. They should also use adequate safety equipment to protect workers and bystanders from injury.

Progressive Die Stamping Process

Progressive die stamping is a process that is used to create metal parts. The process involves using a die to stamp the metal and then Progressive Die Stamping Equipment to create the desired shape. The process is often used to create car parts, but can also be used for other applications.

What are some alternatives to progressive die stamping?

There are a few alternatives to progressive die stamping that can be used in your manufacturing process. Each has its own benefits and drawbacks, so it’s important to weigh them against each other before making a decision. Here are a few of the most popular options:

1. Slot die stamping

Slot die stamping is a popular option because it’s quick and easy to use. You simply place the part you want to stamp into the machine, press the button, and wait for the stamp to finish. The downside is that it’s not as precise as progressive die stamping, so you’ll need to adjust your stamps often.

2. Embossing

Embossing is similar to slot die stamping in that you place the part into the machine and press the button. However, instead of using a stamp, an embosser uses pressure to create raised areas on the part. This gives your product a more finished look and makes it easier to read labels or text printed on the part. Because embossing is more labor-intensive than slot die stamping, it’s usually used for higher-quality products.

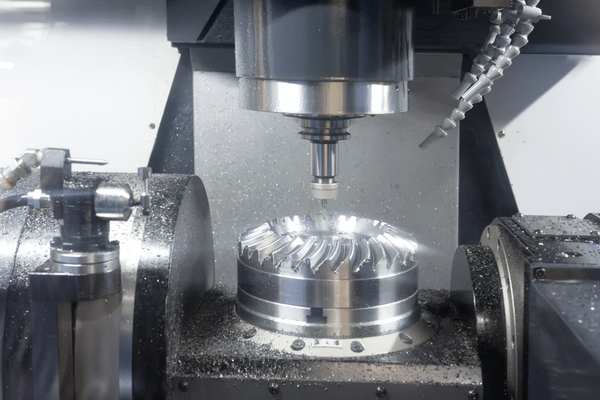

CNC machining is a more advanced option that allows you to create extremely precise stamps. You’ll need to invest in a machine that’s capable of this level of precision, but the payoff is a product that’s accurate and looks professional. CNC machining is usually used for products that require a high level of accuracy, such as medical devices or aerospace parts.

Ultimately, it’s important to decide what’s most important to you when choosing an manufacturing process. If speed is your top priority, then slot die stamping may be the best option for you. On the other hand, if you’re looking for the highest degree of precision possible, CNC machining may be the best fit for you.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.