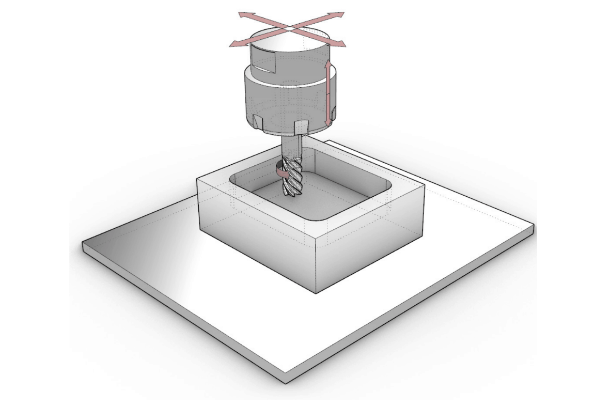

Commercially Pure (Titanium Grade 2)

Discover everything you need to know about Commercially Pure (Titanium Grade 2) with ETCN’s informative guide.

Details of Commercially Pure (Titanium Grade 2)

| Property | Value |

|---|---|

| Alternative Names | CP Titanium, Grade 2 Titanium |

| Composition | Titanium, 99.2% min |

| Mechanical Properties | Yield Strength: 275 MPa, Tensile Strength: 345 MPa, Elongation: 20%, Hardness: 70 HRB |

| Physical Properties | Density: 4.51 g/cm3, Melting Point: 1668 °C, Specific Heat Capacity: 0.52 J/g·°C |

| Thermal Properties | Thermal Conductivity: 20.7 W/m·K, Coefficient of Thermal Expansion: 8.6 µm/m·K |

| Electrical Properties | Electrical Resistivity: 0.420 µΩ·m |

| Post Treatments | Heat treatment, pickling, chemical etching |

| Common Applications | Aerospace, chemical processing, marine |

| Additional Information | Resistant to corrosion in various environments, lightweight, biocompatible |

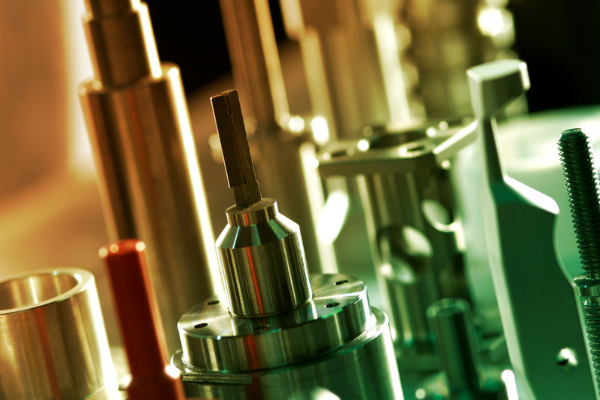

Blogs related to Titanium CNC Service

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Commercially Pure (Titanium Grade 2): Frequently Asked Question

• Grade 2 Titanium is an unalloyed metal with a superior strength-to-weight ratio, excellent corrosion resistance, and weldability.

• Its primary advantage is its combination of high strength and low weight, making it ideal for aerospace, medical, automotive, and marine applications.

• Compared to other metals such as stainless steel or Inconel, Grade 2 Titanium offers improved fatigue strength properties – allowing for lighter structures without sacrificing durability.

• Additionally, its biocompatibility makes it suitable for medical implants and prosthetics.

• Commercially Pure Titanium Grade 2 is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, weldability, and fatigue strength.

• This type of titanium is ideal for aircraft components that are subject to high vibration levels, such as landing gear struts, door panels, and fasteners.

• Its superior fatigue strength means it can withstand cyclic loading without degrading the metal structures.

• It is also suitable for nonstructural components such as cabin furniture and air ducts due to its lightweight and corrosion resistance.

• Additionally, this grade of titanium has been used for creating heat shields in engines with temperatures up to 1600°C (2910°F).

• Grade 2 Titanium is an ideal choice for aerospace applications as it reduces weight while keeping structural integrity intact.

• Commercially Pure Titanium Grade 2 is a strong and lightweight metal, ideal for applications requiring superior performance.

• It offers an excellent strength-to-weight ratio, high ductility, and hardenability, plus corrosion resistance and heat resistance up to 1600°C (2910°F).

• Commercially Pure Titanium Grade 2 is ideal for aircraft components that require increased payload capacity and the ability to withstand vibrations during flight.

• Its corrosion resistance makes it suitable for power plants and petrochemical facilities, and its tensile strength makes it suitable for extreme operational environments.

• Commercially Pure Titanium Grade 2 combines reliability, cost-effectiveness and resilience in one versatile material.

• Commercially Pure Titanium Grade 2 provides superior performance and safety for industrial applications due to its impressive properties.

• Its tensile strength is highly resistant to deformation, and its strength-to-weight ratio allows for heavier loads with the same weight.

• Its features make it ideal for aircraft components, protective wall panels at power plants, heat shields in engines, and more.

• Cost-effective, efficient, and safe working environment are benefits of using Commercially Pure Titanium Grade 2 over other titanium alloys.