Stainless Steel 440C

Looking for information about Stainless Steel 440C? Look no further than ETCN for comprehensive and reliable details on this versatile material!

Details of Stainless Steel 440C

| Name of Steel | Stainless Steel 440C |

|---|---|

| Alternative Names | UNS S44004, ASTM A276 Type 440C, AMS 5630, AMS 5880 |

| Composition/Alloy | Chromium 16-18%, Manganese 1%, Carbon 0.95-1.20%, Silicon 1%, Molybdenum 0.75%, Phosphorus 0.04%, Sulfur 0.03%, Iron balance |

| Mechanical Properties | |

| - Tensile Strength | 760-2070 MPa (110-300 ksi) |

| - Yield Strength | 275-1900 MPa (40-275 ksi) |

| - Elongation at Break | 14-30% |

| - Hardness (Rockwell C) | 58-65 |

| Physical Properties | |

| - Density | 7.7 g/cm³ |

| - Melting Point | 1480-1530 °C (2700-2780 °F) |

| - Thermal Conductivity | 24.9 W/m·K at 100°C |

| - Specific Heat Capacity | 0.46 J/g·K |

| Thermal Properties | |

| - Coefficient of Thermal Expansion | 10.4-11.3 µm/m·K |

| - Thermal Conductivity | 24.9 W/m·K at 100°C |

| Electrical Properties | |

| - Electrical Conductivity | 1.03 × 10^6 S/m |

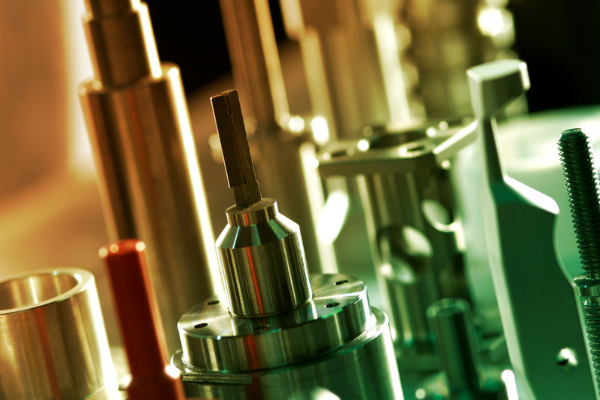

| Post Treatments | Annealing, quenching, tempering, cryogenic treatment |

| Common Applications | Bearings, knives, surgical instruments, ball bearings, valve parts, aerospace components |

| Advantages/Disadvantages | High hardness and wear resistance, good corrosion resistance, poor impact resistance, difficult to machine and grind, relatively expensive compared to other stainless steel grades |

Blogs related to Stainless Steel Machining

Top 12 China CNC Machining Service Providers in 2023 You’ve...

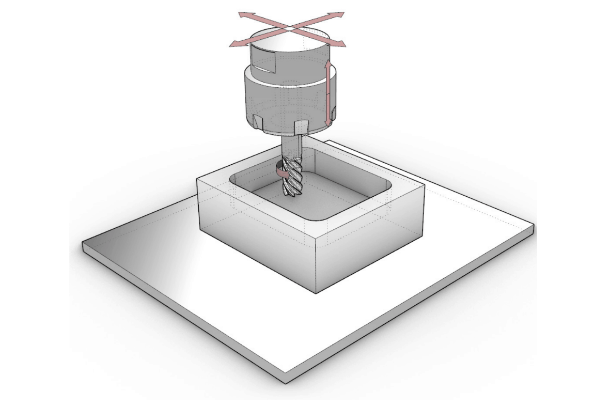

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Stainless Steel 440C: Frequently Asked Question

• 440C stainless steel is a high-carbon martensitic stainless steel with superior wear, corrosion, and edge retainment properties.

• It features a Rockwell C hardness rating of 58-65, making it highly scratch and abrasion resistant, ideal for products subject to repeated wear.

• Its higher chromium content gives it greater corrosion resistance in harsher environmental conditions.

• Its increased wear resistance and excellent edge retention make it an ideal choice for demanding applications.

• Hardening stainless steel 440C is the process of increasing its hardness, wear resistance, and durability.

• Common hardening processes used for this material include annealing, quenching, tempering, and cryogenic treatment.

• Proper precautions must be taken, including using scale-preventative oils during annealing, insulation between heated and cooled surfaces when quenching, not overheating the steel, and knowing the desired finish before starting a hardening process.

• Through careful consideration of all factors involved, materials scientists can utilize any combination of hardening processes for maximum results when working with stainless steel 440C.

• Heat-treating stainless steel 440C is the process of heating and cooling to change its properties, making it stronger, harder, or more wear resistant.

• This process starts with heating the material to a specified temperature and then quickly cooling it through annealing, quenching, tempering, or cryogenic treatment.

• After heat treating stainless steel 440C, it should be inspected for warping or distortion and checked for any loss of corrosion resistance due to its high chromium content (16-18%).

• Stainless steel 440C is a high-carbon martensitic type of stainless steel with excellent corrosion, toughness, and wear resistance due to its 16-18% chromium content.

• It is ideal for applications requiring durability even in harsh environments, such as aerospace industry components and medical and dental use.

• Heat treating this material can increase its hardness, strength, and wear resistance by using processes such as annealing, quenching, tempering or cryogenic treatment.

Stainless Steel 440C is often used for applications that require enhanced resistance to abrasion and corrosion.

Such as:

-Medical and dental instruments

-Aerospace parts

-Industrial tools and components

-High-performance automotive parts

-Cutlery and knives

-Valves and pump components in the chemical industry.