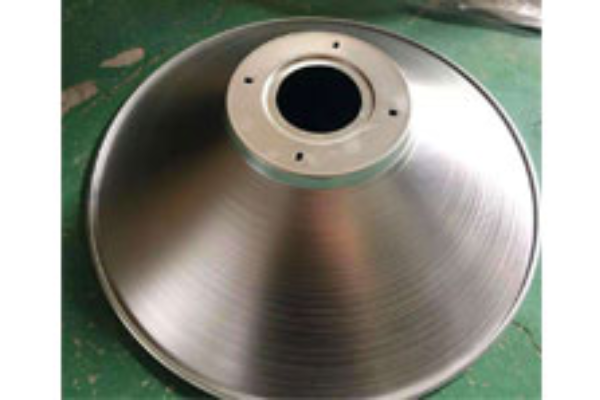

TOP CNC Metal Spinning From China

ETCN offers high-quality CNC metal spinning parts, as well as promotional products for your business.

CNC Metal Spinning

ETCN is a CNC metal spinning company specializing in producing high-quality spun metal products. We have over 20 years of experience in the metal spinning industry, and our team of skilled craftsmen can produce products that meet the highest standards of quality and durability. Our products are used in various industries, including automotive, aerospace, and construction, and we are proud to be a leading supplier of CNC spun metal products.

Our core advantages include our experience, skilled workforce, and state-of-the-art facilities. We believe these advantages allow us to provide our customers with the best products and services. We are committed to meeting our customers’ needs and look forward to serving you in the future.

What Is The CNC Metal Spinning?

CNC Metal Spinning is a process where a piece of metal is shaped by spinning it on a lathe. This process can create various shapes and sizes of metal objects. The spinning motion of the lathe allows for the shaping of the metal without any deformities. This makes CNC Metal Spinning an efficient and accurate way to create metal objects.

Advantages of CNC Metal Spinning

There are many advantages of CNC metal spinning. One of the main advantages is that it allows for a high degree of accuracy and repeatability. This means that parts made using CNC metal spinning will be identical to each other, which is essential for many applications. Another advantage of CNC metal spinning is that it is much faster than traditional methods. This means that parts can be produced quickly and efficiently.

Casting FAQs

Frequently Asked Questions.

Unclear Marking During Casting?

1. The mark on the mold is not clear enough (the reason for the mold);

2. The markings on the mold are not clear. You can analyze whether the particle size of the following molding sand is fine enough and whether the strength is high enough;

3. The refractoriness of the mold and coating is not enough.

4. Another factor that is easily overlooked is the casting location of the casting mark. When determining the casting position, try to keep the casting mark on the bottom or side to avoid being on the top surface.

Why Can't The Inner Processing Of Aluminum Die-casting Hole Exceed 0.25mm?

With the addition of silicon film as a process, molding has changed. Silicon is used to create molds in the shape of something that has been designed using aluminum and other metals. When aluminum cools down in the persimmon, particles start to form on top of it. This silicon layer is known as a silicon film that starts at .2mm thick to .9mm thick. Some design houses use this silicon film as a self-lubricating surface–the bearing performance will be shortened if done too much.

Easy To Crack When Die-casting Thin-walled Products

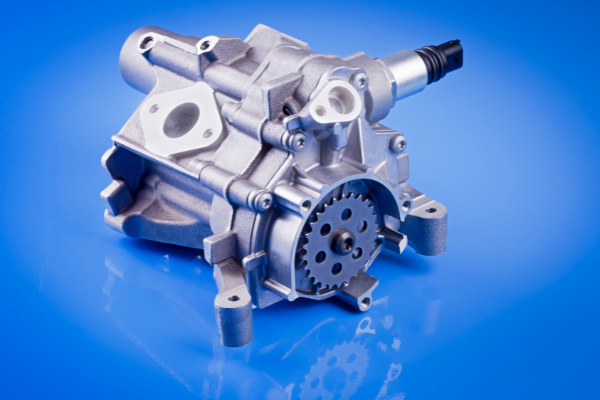

Die-casting is a manufacturing process that produces metal parts by pressing the molten material, usually bronze or aluminum, into a mold. The most common type of die-cast part is a cylinder, but other shapes can be made as well.

The main problem with die-casting thin-walled products is that the material can easily crack when it cools. This can cause the part to fail when it’s used, so it’s important to take precautions when making them.

One way to prevent cracking is to use a thicker walled die. This will make it more difficult for the material to break apart, and it will also result in a stronger part. Another method is to use a thermal barrier material. This will help to keep the material from cooling too quickly, and it will also prevent cracks from forming.

If you’re die-casting thin-walled products, it’s important to take precautions to avoid cracking. By using a thicker walled die or using a thermal barrier material, you’ll be able to produce strong parts that won’t fail later on.

Metal Splashing During Die Casting

Die casting is a process that creates objects from molten metal. The molten metal is poured into a die, which shapes the metal and creates the object. Sometimes small pieces of metal can splash out of the die during the casting process. This can create problems for the object being created, and it can also be dangerous.

Metal splashing during die casting can cause problems with the finished product. The pieces of metal that splash out can deform the die, creating inconsistencies in the shape of the object. This can lead to defects in the object, as well as injuries to workers involved in the process. Metal splashing also poses a danger to bystanders, as flying pieces of metal could injure them.

To prevent metal splashing during die casting, manufacturers should take precautions to keep the die clean. They should also use adequate safety equipment to protect workers and bystanders from injury.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.