For many manufacturers, CNC machining steel is crucial to producing their final product. It’s a precision process that must be undertaken with the utmost care and expertise by professionals who understand the intricate processes involved in creating large and small pieces of metal. Failing to get these processes right can lead to losing time, money, and materials, so it is imperative to get it right the first time. With this in mind, we created this comprehensive guide to CNC machining steel. As well as outlining the basic principles behind this fabrication technology, we will walk you through some practical considerations when choosing a service provider for your project needs – from material selection to post-process finishing touches.

Introduction to CNC Machining Steel

Steel is a solid and durable material widely used in modern manufacturing applications. Steel is a critical component in countless products and systems, from building construction to industrial machinery and everything in between. One of the most efficient and effective ways to shape and form steel into precision components is through CNC machining. In this article, we will explore the history of CNC machining steel, its advantages, and challenges, and provide an overview of the process.

History of CNC Machining Steel

CNC (Computer Numerical Control) machining has been around for several decades and has revolutionized the manufacturing industry. Before CNC machines were introduced, manual machining processes were used, which required extensive labor and expertise. On the other hand, CNC machining involves computer programs that automate the manufacturing process, allowing for greater accuracy, efficiency, and consistency.

Advantages of CNC Machining Steel

There are several advantages to using CNC machining steel. Firstly, CNC machines can produce precise and identical parts with ease. This results in less wastage of material and reduces the possibility of errors. Secondly, CNC machines can operate continuously, 24 hours a day, 7 days a week, resulting in faster and more efficient production rates. Thirdly, CNC machines can be easily reprogrammed, allowing manufacturers to shift from one product to another quickly. Finally, CNC machines also allow for greater control over the manufacturing process, which means tighter quality control and fewer defects.

Challenges of CNC Machining Steel

Despite the numerous advantages of CNC machining steel, there are also some challenges to overcome. One of the biggest challenges is the cost of purchasing and maintaining CNC machines. Additionally, CNC machine operators need specialized training and expertise, which can sometimes be a barrier to entry. Also, setting up the CNC machine for a specific product can take time and effort; mistakes during this process can result in wasted time, effort, and materials.

CNC Machining Steel Process Overview

CNC machining steel involves several steps, each requiring careful planning and execution. The first step is to design the product using a CAD (Computer-Aided Design) software program. The next step is to create a CAM (Computer-Aided Manufacturing) program that converts the CAD design into machine-readable code. Once the code is made, it is transferred to the CNC machine, and the steel component can begin machining. The CNC machine cuts away excess material using various cutting tools, such as drills, lathes, or mills, to create the desired shape and size. Finally, the finished product is inspected for quality and accuracy before it is released for use.

Conclusion

CNC machining steel is an exact and efficient process that has revolutionized the manufacturing industry. Its ability to produce identical parts quickly and accurately has become an indispensable tool for modern manufacturing. While there are challenges to be overcome, the advantages far outweigh them, and we can expect to see CNC machining of steel increasingly used in various industries. Whether you need a few small components or a large production run, CNC machining steel is the way to go.

Materials for CNC Machining Steel

Regarding CNC machining steel, various materials and processes can be used to create the desired results. Whether you’re looking for rapid prototypes or custom-made parts with complicated geometries, understanding the different types of materials available and their properties is crucial when selecting which option works best for your project. In this blog post, we’ll explore the various metals suitable for CNC machining steel and look at how they should be used to achieve optimal precision and quality. With this knowledge in hand, let’s get into it!

Understanding the Differences between Alloy Steel and Carbon Steel in CNC Machining

When it comes to CNC machining, selecting the suitable steel material is critical to ensuring a high-quality end product. Steel is the most commonly used material in CNC machining due to its high strength and durability. However, not all steels are created equal. This article explores the differences between two popular types of steel used in CNC machining – alloy steel and carbon steel.

Alloy Steel:

Alloy steel is a type of steel that contains other elements such as nickel, chromium, and molybdenum. Adding these elements enhances the steel’s properties and makes it more suitable for specific applications. One of the primary characteristics of alloy steel is its high strength. It is also incredibly tough and can withstand high levels of wear and tear. These properties make it famous for demanding aerospace, automotive, and industrial manufacturing applications. Two of the most common types of alloy steel used in CNC machining are 4140 and 4340. 4140 is an all-purpose steel with high tensile strength and toughness, while 4340 is known for its high fatigue strength and excellent flexibility.

Carbon Steel:

Carbon steel is a type of steel that is primarily composed of iron and carbon. The amount of carbon present determines its properties. Carbon steel is often praised for its high ductility and malleability, making it easy to work with. Another significant advantage of carbon steel is its low cost compared to other steels. Due to its low cost and versatility, it is commonly used in construction, infrastructure projects, and general-purpose machinery manufacturing. The most widely used carbon steels in CNC machining are 1018 and 1045. 1018 is a low-carbon steel with excellent weldability, while 1045 is a medium-carbon steel with high tensile strength and wear resistance.

Conclusion:

Choosing between alloy and carbon steel for a CNC machining project depends on several factors, including the application, design requirements, and budget. Alloy steel is preferred for applications that require high strength and toughness, while carbon steel is suitable for general-purpose machinery manufacturing. Engineers and manufacturers can decide on the best steel material for a particular CNC machining project with the information provided.

Steel Manufacturing Process

Steel is vital in various industries, including construction, transportation, and manufacturing. Making steel involves two primary methods; primary and secondary production. Each method has distinct stages that determine the type of steel produced.

Primary Production

The primary production process involves transforming raw materials into liquid steel, including iron ore, coal, and limestone. The method consists of the following stages:

1) Raw Material Preparation: The raw materials are carefully selected, crushed, and blended to produce a consistent mixture.

2) Roasting: The blended mixture is roasted in a blast furnace at high temperatures, producing blast furnace iron or Direct Reduced Iron (DRI).

3) Liquid Steel Production: The molten iron is further processed to produce liquid steel, which can be cast into different shapes like slabs, sheets, and billets.

Types of Steel Produced: The primary production process can produce various kinds of steel, including carbon steel, alloy steel, and stainless steel.

Secondary Production

The secondary production process involves recycling steel scraps in industrial waste, automobiles, and scrap metal. The process is known as the electric arc furnace process and consists in melting scrap steel in an electric arc furnace to produce molten steel. The process includes the following stages:

1) Raw Material Preparation: The steel scraps are collected and sorted according to their properties.

2) Melting: The sorted steel scraps are melted in an electric arc furnace, producing molten steel.

3) Refining: The molten steel is refined to remove impurities and improve quality.

Types of Steel Produced: The secondary production process can produce various kinds of steel, including low-carbon steel, high-carbon steel, and tool steel.

In conclusion, making steel involves two primary and secondary methods, each with distinct stages determining the steel type produced. While the primary production method transforms raw materials into liquid steel, the secondary production method recycles steel scraps to produce molten steel. With expert knowledge in steel manufacturing, companies can have quality steel products that meet the needs of various industries.

Steel Grades and Characteristics

CNC machining requires the use of specific steel grades that possess unique properties and characteristics. Several steel grades are commonly used in CNC machining, each with advantages and disadvantages.

Low Carbon Steel

Low carbon steel is a commonly used steel grade due to its excellent weldability, machinability, and formability. It is also relatively inexpensive and easy to work with, making it ideal for automotive parts, construction materials, and general fabrication applications. Low-carbon steel has a carbon content of 0.05-0.25%, making it easy to work with and manipulate into various shapes.

High Carbon Steel

On the other hand, high-carbon steel is a lot stronger than low-carbon steel but more difficult to machine. It has a carbon content of 0.60-1.0%, making it ideal for applications that require high strength and hardness, such as blades, cutting tools, and springs.

Stainless Steel

Stainless steel is another popular steel grade used in CNC machining. It is resistant to corrosion, making it ideal for applications that require high hygiene levels, such as food processing, medical instruments, and marine equipment. Stainless steel also provides excellent strength and durability, making it a good choice for structural applications. However, it is more expensive and difficult to machine than low-carbon and high-carbon steel.

Tool Steel

Tool steel is a high-performance steel grade with excellent wear resistance and toughness. It is commonly used for cutting tools, shaping, and stamping dies. Tool steel is also known for retaining its hardness and strength at high temperatures, making it ideal for hot work applications. However, it is more expensive than other steel grades and requires special handling and machining techniques.

The selection of the correct steel grade for a product depends on various factors such as size, geometry, required mechanical properties, and intended use. It is crucial to consult with a knowledgeable CNC machining partner who can recommend the perfect steel grade for your project.

In conclusion, steel grades and characteristics are essential considerations for CNC machining. The selection of the correct steel grade can impact a product’s quality, performance, and overall success. By understanding the properties and characteristics of each steel grade, manufacturers can make informed decisions and ensure the success of their projects.

Selecting the Right Steel

When it comes to CNC machining projects, selecting the correct type of steel is critical for achieving the desired outcomes. As a materials engineer, vital factors must be considered in the steel selection process. This guide aims to examine these factors, outline the role of machining in steel selection, and provide key questions to ask to find the correct steel for the job.

Factors to Consider When Selecting Steel for CNC Machining

Strength, durability, and corrosion resistance are critical when selecting steel for CNC machining projects. Power determines the stress the steel can handle before it deforms or breaks. Durability measures a steel’s ability to withstand wear and tear. Finally, corrosion resistance evaluates the steel’s ability to resist rust and other types of corrosion.

Additionally, the specific properties required for CNC machining need to be considered. Machinability and hardness are important properties as they can impact the success of a CNC machining project. Machinability refers to how easily a material can be machined, while hardness measures a material’s resistance to deformation.

The Role of the Machining Process in Steel Selection

The machining process can significantly impact the final product’s properties, so it is essential to select steel that can withstand the stress of the machining process without compromising the end product’s quality. The machining process can cause thermal deformation, which can negatively impact the final product’s dimensional accuracy and affect the steel’s properties, such as its strength, hardness, and machinability.

The Importance of machining in steel selection can also be seen in the machining tolerance required for the project. The tolerance refers to the allowable deviation from the final product’s nominal or desired dimensional specifications. The selection of steel for the project will depend on the required patience, and selecting the correct steel can help ensure that the end product meets the tolerance specifications.

Key Questions to Determine the Right Steel for the Job

To determine the correct steel for the project, vital questions must be asked. These questions include:

What is the project’s end goal, and what are the specific performance requirements? Understanding the goals and needs of the project can help narrow down the selection of steel.

What are the production standards and regulations that must be adhered to? Different industries may have specific standards for the materials used in CNC machining projects.

What is the budget for the project? The budget may impact the selection of steel, as higher-quality steel can be more expensive.

What is the required machining tolerance? The required tolerance can impact the selection of steel for the project.

Is there a preference for a specific type of steel? Certain types of steel may be preferred due to their properties, such as stainless steel for its corrosion resistance.

By answering these questions and more, it will become easier to determine the correct type of steel for the CNC machining project. Ensuring that the right steel is selected can lead to a successful project with an end product that meets or exceeds the desired specifications.

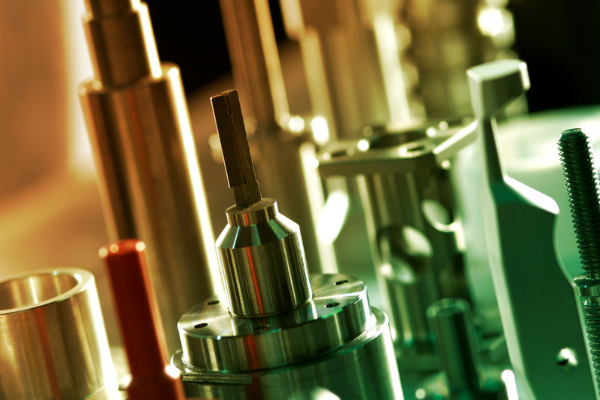

CNC Machining Tools and Equipment

Choosing the right tools and equipment for steel machining is essential to achieve the desired results with precision and accuracy. The right tools must be selected based on the intended use of the steel product, as different types of steel require various devices for optimal performance. Factors such as material hardness, surface finish, tolerance requirements, and production volumes should all be considered when selecting tools for machining steel products. Additionally, proper maintenance of tools is essential to ensure their longevity and maintain their performance over time.

CNC Machines for Steel Machining

Steel machining is a complex process that requires precision and accuracy to produce high-quality products. CNC machines have become famous for steel machining because they consistently provide excellent results. However, choosing a suitable CNC machine for steel machining is difficult. In this guide, we’ll explore the different types of CNC machines used for steel machining and the key factors to consider when selecting a device.

A. Types of CNC Machines

Turning

Turning is a CNC machining process that uses a cutting tool to remove material from the rotating workpiece. The turning process creates cylindrical components such as shafts, bolts, and nuts. Turning machines come in different configurations, including horizontal and vertical lathes, and the choice depends on the part’s complexity and the production volume.

Milling

Milling is a CNC machining process that uses a cutting tool to remove material from the workpiece. Milling is suitable for creating complex shapes, slotting, and drilling holes. Milling machines come in various configurations, including vertical and horizontal mills, and the ideal choice depends on the project’s requirements.

Drilling

Drilling is a CNC machining process that uses a rotating drill to create holes in the workpiece. The drilling process begins with holes in engine blocks, wheel hubs, and transmission components. The drilling machine type depends on the hole size, depth, and material hardness.

B. Factors to Consider When Choosing CNC Machines for Steel Machining

Machine Size and Capacity

The size and capacity of the machine are crucial factors to consider when selecting a CNC machine for steel machining. The machine’s size and capacity should match the size of the workpiece and the production volume. A giant machine can produce more prominent parts and handle a higher production volume.

Tooling Compatibility

The tooling compatibility of the CNC machine is a crucial factor to consider when choosing the ideal machine for steel machining. The device should be compatible with steel machining tooling, including drill bits, end mills, and other cutting tools. Using incompatible tooling can result in poor-quality parts and reduced productivity.

Cutting Speed and Accuracy

The cutting speed and accuracy of the machine are critical factors that affect the quality of the finished product. The ideal CNC machine for steel machining should be capable of high cutting speeds while maintaining accuracy. The machine should be able to produce smooth surface finishes consistently.

Examples of CNC Machines for Steel Machining:

Haas VF-6SS Vertical Machining Center

This CNC machine is a high-speed, powerful, and precise machine suitable for steel machining. It is equipped with a high-speed spindle and a 40+ tool capacity changer. The Haas VF-6SS is ideal for producing complex shapes and designs, including aerospace and medical components.

DMG Mori NLX 2500

This CNC machine is a high-performance turning center that produces cylindrical parts such as shafts, bolts, and pins. It has a maximum turning diameter of 14.8 inches and a maximum turning length of 25.2 inches. The DMG Mori NLX 2500 has a high-speed spindle and turning tools, making it suitable for steel machining.

Conclusion:

Choosing the suitable CNC machine for steel machining requires careful consideration of various factors, including machine size and capacity, tooling compatibility, and cutting speed and accuracy. Selecting a device that matches the project’s requirements is essential to ensure high-quality parts and increased productivity. With this guide, you can make an informed decision when selecting a CNC machine for steel machining.

Tooling and Workholding Devices

Working with metal requires precise and accurate manufacturing techniques. The use of tooling and work-holding devices is crucial in achieving this goal. This guide will discuss the Importance of tool holders, cutting tools, and work-holding devices. We’ll also provide tips on selecting the appropriate tooling and work-holding devices for different manufacturing processes and discuss the proper maintenance and care for these tools to ensure efficient and effective operations.

A. Tool Holders

Tools holders are components that hold cutting tools in place during the manufacturing process. They provide precise and accurate cutting tool positioning for creating quality and repeatable parts. Tool holders come in various shapes and sizes, from collets to chucks, and their geometry depends on the cutting tool type.

When selecting a tool holder, it’s essential to consider factors such as the size and shape of the cutting tool, the spindle’s rotation speed, and the machined material. It’s also necessary to know the taper size of the machine’s spindle to ensure a proper fit.

B. Cutting Tools

Cutting tools are used to remove material from the workpiece during the manufacturing process. Various cutting tools, such as drills, end mills, reamers, and taps, come in multiple shapes and sizes to fit specific applications.

When selecting a cutting tool, it’s essential to consider factors such as the machined material, the workpiece’s geometry, the surface finish required, and the type of operation (such as drilling, milling, or turning).

C. Workholding Devices

Workholding devices hold the workpiece in place during the manufacturing process. They provide stability and accuracy, essential for creating precise and repeatable parts. There are three most common types of work-holding devices:

Clamps: Clamps hold the workpiece by applying pressure to the sides. They come in various shapes and sizes, from simple C-clamps to complex hydraulic clamps.

Vises: Vises hold the workpiece by applying pressure from the top and the bottom. They’re commonly used for milling and drilling operations and come in various shapes and sizes to fit specific applications.

Chucks: Chucks hold the workpiece by gripping it from the inside. They’re commonly used for turning operations and come in various shapes and sizes to fit specific applications.

When selecting a work-holding device, it’s essential to consider factors such as the size and shape of the workpiece, the machining operation, and the type of machine being used.

Maintenance and Care

To ensure efficient and effective operations, it’s essential to maintain and care for your tooling and work-holding devices. Here are some tips:

Keep your tools and work-holding devices clean and free of debris.

Store your tools in a clean and dry environment to prevent corrosion.

Inspect your tools and work holding devices regularly for damage or wear and replace them as needed.

Use the appropriate lubrication for your tools and work-holding machines.

Follow the manufacturer’s recommendations for maintenance and care.

In conclusion, tooling and work-holding devices are vital in precision parts manufacturing. You can ensure efficient and effective operations, product quality, and repeatable parts by selecting the appropriate tooling and work-keeping machines and maintaining them properly.

Coolant Systems and Lubricants

CNC machining technology has revolutionized the manufacturing industry, enabling the creation of precise and complex parts quickly. However, complex machining processes generate heat, friction, and wear, significantly impacting the machine’s efficiency and lifespan. This is where coolant systems and lubricants come into play.

A. Importance of coolant systems and lubricants in CNC machining

Coolant systems and oils are critical for CNC machine operation, as they ensure the tool operates efficiently and extends its lifespan by eliminating the heat generated during cutting. Coolants and lubricants also prevent wear and tear, reducing the need for repairs and expensive replacements.

Coolants and lubricants flush chips and debris generated during the cutting process from the machine, promoting the cleanliness of the work environment. Coolants and fats are essential to CNC machining, enabling efficient and productive operations.

B. Types of coolant systems and lubricants

Three primary types of coolant systems and lubricants are used in CNC machining, each with advantages and disadvantages.

Flood coolant

Flood coolant systems are the most common type and contain water and additives sprayed onto the tool during cutting. Flood coolants eliminate heat, remove debris, and lubricate the mechanism. This system is best suited for heavy cutting processes, as it reduces tool wear and prevents tool breakage.

However, flood coolant systems increase machine maintenance requirements, as the coolant can become contaminated with chips and debris, leading to clogged lines and filters. This system is also unsuitable for small and intricate parts, as the coolant can obstruct the operator’s view and cause inaccuracies.

Mist coolant

Mist coolant systems use a fine mist of oil-based lubricants and distilled water to cool and lubricate the tool. The system is ideal for small and intricate parts, promoting accurate cutting and prolonging tool life.

Mist coolant systems require less maintenance than traditional flood coolant systems, as they do not collect debris, and the coolant is recycled. However, this system can be expensive and has limited application for heavy cutting operations.

Dry lubricant

Dry lubricant systems use a powdered lubricant, such as graphite or molybdenum disulfide, to reduce friction and heat during cutting. The system is ideal for high-speed machining operations, as it eliminates the need for a coolant system and reduces chip accumulation.

Dry lubricant systems require no maintenance, have a low environmental impact, and are suitable for small, intricate parts. However, this system is not ideal for heavy cutting and can cause an abrasive effect on certain materials.

Best Practices for coolant system and lubricant maintenance

The quality of the coolant and lubricant used in a CNC machine significantly impacts performance and longevity. Implementing good coolant maintenance practices, including regular cleaning, inspection, and replacement.

Choosing the proper coolant and lubricant

The choice of coolant and lubricant used in CNC machining largely depends on the specific machining process, the machining material, and the desired finished product. It is crucial to consult with machining experts to determine the ideal coolant and lubricant for individual jobs.

Conclusion

CNC machining is a complex process that involves precision and efficiency. Coolant systems and lubricants play a significant role in promoting these aspects. A regularly maintained and adequately selected coolant and lubricant system can increase machine efficiency, reduce downtime, and ultimately lower costs. The Importance of the best practices for coolant systems and lubricant maintenance cannot be emphasized enough to maximize CNC machine efficiency and minimize cost expenses.

Measuring Devices for CNC Machining

Accurate measurements are crucial in CNC machining as they impact both the quality of the product and overall efficiency. Machining involves using computer-controlled tools to cut, shape, and form materials into products. The precision of the machining process is only as good as the precision of the measuring devices being used. Inaccurate measurements can result in defective products, production delays, and even machinery damage; therefore, it is essential to clearly understand the different measuring devices available and how they are used in CNC machining.

Types of Measuring Devices

Micrometers

Micrometers, or outside micrometers, are devices used to measure small distances accurately. They are commonly used in CNC machining to measure the outer diameter of objects such as shafts, bolts, and screws. Micrometers offer a high degree of accuracy and are available in various sizes. They are easy to handle and can measure to within 0.001 mm accuracy. They are also robust and can withstand rough handling.

Pros:

Accurate measurement of small distances

The high degree of accuracy

Available in various sizes

Durable and robust

Cons:

Expensive compared to other measuring devices

Requires skill to use properly

Regular calibration needed

Proper usage:

Clean the micrometer: Before using it, ensure it is clean and free from any dirt or debris affecting its accuracy.

Zero the micrometer: Place the micrometer on a flat surface and turn the thimble to zero. This sets the reference point for measurement.

Measure the object: Place the thing to be measured between the spindle and the anvil, then turn the thimble to close the jaws until they make contact with the item. Read the measurement from the micrometer scale.

Example of usage:

A machinist needs to measure the outside diameter of a shaft before cutting it to size. They use a micrometer to measure the diameter and obtain an accurate measurement to ensure that the post is the correct size for the intended use.

Vernier Calipers

Vernier calipers are measuring devices used to accurately measure objects’ thickness, diameter, and depth. They have two jaws that can be moved along a scale and provide precise measurements in metric and imperial units. They are commonly used in CNC machining to measure the thickness of parts such as plates and sheets.

Pros:

Accurate measurement of thickness, diameter, and depth

Can measure in both metric and imperial units

Available in various sizes

It can be used in different positions

Cons:

Requires skill to use properly

It can be not easy to read accurately

Not suitable for measuring tiny objects

Proper usage:

Clean the vernier calipers: Ensure they are clean and free from any dirt or debris affecting their accuracy.

Zero the vernier calipers: Place the jaws together and turn the dial to zero. This sets the reference point for measurement.

Measure the object: Place the thing between the jaws and read the measurement from the scale and vernier lines. Subtract the zero reading to obtain an accurate size.

Example of usage:

A machinist needs to measure the thickness of a metal plate before cutting it to size. They use a vernier caliper to obtain an accurate measurement and ensure that the scale is the correct thickness for the intended use.

Dial Indicators

Dial indicators are devices used to measure objects’ relative position accurately. They consist of a dial face and a spring-loaded plunger that moves along a reference plane. They are commonly used in CNC machining to measure parts’ position and check for deflection or run out.

Pros:

Accurate measurement of relative position

The high degree of sensitivity

It can be used in different positions

Easy to read the size from the dial face

Cons:

Limited measurement range

Fragile and can be damaged by rough handling

It can be expensive compared to other measuring devices

Proper usage:

Mount the dial indicator: Attach the magnetic base of the dial indicator to the machine or workpiece to be measured.

Zero the dial indicator: Press the plunger against the reference plane and turn the dial to zero. This sets the reference point for measurement.

Measure the object: Place the plunger against the object to be measured and read the measurement from the dial face. The dial face can be used to check for deflection or runout.

Example of usage:

A machinist needs to check the accuracy of a component that has been machined. They use a dial indicator to measure the element’s relative position and check for any deflection or runout that could affect its performance.

Steel Milling, Turning, and Drilling

Steel machining is a complex process that requires expertise and precision. Different steel machining processes are used depending on the type of steel being machined, the desired end product, and the desired output quality. Here’s an explanation of the three basic steel machining processes – milling, turning, and drilling – and how each process is unique.

Milling: Steel milling involves removing metal from a workpiece using rotating cutting tools. The cutting tools rotate in a selected direction against the workpiece, resulting in a smooth surface finish. Milling is best suited for creating complex geometries, deep pockets, and grooves in the workpiece surface.

Turning: Turning is machining a rotating workpiece using the cutting tool’s movement. The cutting tool moves in a fixed path, remove metal from the workpiece and create a smooth and precise surface. Turning mostly produces cylindrical or conical surfaces, such as shafts, pins, and pipe connections.

Drilling: Drilling is a steel machining process that involves creating holes in a workpiece using a rotating cutting tool with multiple blades. Drilling is one of the most commonly used processes for machining small to medium-sized cavities in steel workpieces.

To ensure successful steel machining, there are specific factors to consider. Here are some tips for successful steel machining:

Choosing the Right Machine Settings: To achieve optimal material removal rates, selecting the correct machine settings is crucial. The settings should match the type of steel machined and the machining process used. The appropriate machine settings should consider several factors, including the steel’s hardness, the machine’s power, and the desired output quality.

Proper Use of Tooling and Workholding Devices: Proper use of toolings and work-holding devices, such as jigs and fixtures, are essential to achieve precision and accuracy in steel machining. Tooling includes cutting tools, inserts, and drill bits. Workholding devices grip the workpiece in place while it is machined securely. Jigs and fixtures help maintain consistent positioning and orientation of the workpiece.

Regular Maintenance and Upkeep: Machine maintenance and upkeep are crucial to prevent wear and tear of the machines. Regular cleaning and routine inspection can ensure the machines are running correctly and reduce downtime. Keeping the devices clean and well-lubricated is advisable to prevent rust and other issues that can lead to damage.

In conclusion, Steel milling, turning, and drilling have unique features and uses in steel machining. By understanding each process’s strengths and limitations and following the guidelines for successful steel machining, manufacturers can produce high-quality steel-based items, such as automotive parts, aerospace components, and construction materials. The correct machine settings, proper use of tooling and work-holding devices, and regular maintenance and upkeep are crucial to achieving optimal results in steel machining.

CNC Machining Techniques for Steel

Are you looking for ways to improve your CNC machining steel services? With modern CNC techniques, you can get precise results with improved efficiency and lower costs. In this blog post, we’ll explore strategies that can be employed when working with steel to make the most of this material and deliver top-notch results to your customers. Read on to learn more about some of the best practices and strategies experienced CNC professionals use.

Programming CNC Machines for Steel Machining

As a CNC programmer, it is crucial to understand the various codes and strategies involved in steel machining. This comprehensive guide will break down G-code and M-code, explain the Importance of choosing the right tool path and machining strategy, and provide tips for optimizing tool changes and feed rates to achieve accuracy, efficiency, and safety.

Understanding G-code and M-code

G-code and M-code are two essential commands used to program CNC machines. G-code (geometric code) tells the machine the specific movements necessary to produce a desired shape or pattern, such as the tool’s position, speed, and direction of travel. M-code (miscellaneous code) controls specific machine functions such as turning coolant on or off, engaging or disengaging the spindle, or stopping the program. Understanding G-code and M-code, and their capabilities, are essential to effectively programming and operating CNC machines for steel machining.

Choosing the right tool path and machining strategy

Choosing the right tool path and machining strategy can make all the difference in achieving a steel part’s desired shape and size. Considerations such as tool size, speed, and depth of cut must be considered. When programming the tool path, choosing a pattern that will remove material most efficiently while minimizing tool wear and maintaining accuracy is essential.

Optimizing tool changes and feed rates for efficiency and accuracy

Efficient and accurate CNC steel machining requires careful attention to tool changes and feed rates. Choosing the right tool for a specific task minimizes downtime between tool changes. Optimizing feed rates for each device and operation can improve machining time and reduce tool wear.

Pre-processing best practices, such as using simulation software to identify potential errors in the tool path and selection, can also improve efficiency and accuracy. Optimizing tool changes and feed rates to keep the machine and tooling in good working condition, including regular maintenance and calibration, is essential.

Conclusion

Programming CNC machines for steel machining requires methodical and precise planning. By understanding G-code and M-code, choosing the right tool path and machining strategy, and optimizing tool changes and feed rates, CNC programmers can achieve accuracy, efficiency, and safety for steel machining. By adopting and refining these best practices over time, CNC programmers can become experts in CNC machining for steel.

Machining Speeds, Feeds, and Surface Finishing

Machining involves cutting, shaping, or removing materials from workpieces to create a specific shape or size. The main variables affecting machining speeds and feeds include the machining process type and the machining material. It is vital to clearly understand these variables to optimize cutting parameters while maintaining quality.

Variables Affecting Machining Speeds and Feeds

Machining processes can be divided into two categories: turning and milling. Turning produces cylindrical objects, whereas milling creates flat or curved surfaces. The cutting speed for turning is typically slower than for milling due to the smaller cutting area. The type of cutter used in a milling process also affects the rate, with end mills requiring faster speeds than face mills.

The material being machined is another critical variable. More complex materials, such as stainless steel, require slower cutting speeds and faster feeds, while softer materials, like aluminum, allow faster speeds and lighter feeds. Abrasive materials such as composites require special attention to prevent tool wear.

Achieving the Desired Surface Finish Through Cutting Parameters and Tool Selection

Surface finishing is an essential aspect of machining. The appearance and performance of the final product are affected by the surface finish. Several factors are crucial when trying to achieve the desired level of surface finish, including cutting parameters and tool selection.

The cutting parameters that influence surface finish include depth of cut, feed rate, and cutting speed. The depth of cut determines the thickness of the chip being removed, and a smaller chip thickness leads to a smoother finish. However, a more significant depth of cut may be required to achieve the necessary material removal rate. The feed rate refers to how fast the material is being removed, and faster feed rates can lead to better surface finishes. Cutting speed affects surface finish by controlling the heat generated during machining, which can cause thermal distortion.

Tool selection is also critical for surface finishing. More complex materials require more rigid and wear-resistant tools, while softer materials require softer tools to prevent deformation. The shape and size of the device must also be considered to ensure an even surface finish.

Avoiding Common Mistakes That Lead to Surface Defects

Machining can be challenging, and even minor issues can result in significant problems. Common mistakes leading to surface defects include tool wear, incorrect geometry, poor fixturing, and improper coolant systems.

Tool wear is a significant problem in machining, and it can cause surface defects, which results in scrapped parts. Using a high-quality tool and maintaining it regularly can minimize tool wear.

Correct tool geometry is vital to achieving the desired surface finish. If the tool’s shape or size is incorrect, it can cause chips to get caught in the cutting edge or lead to excessive vibration. This can result in a poor surface finish.

Poor fixturing can cause workpieces to move during machining, causing errors in size and shape. It can also cause improper chip formation or tool engagement, leading to surface defects.

Improper coolant systems can cause several issues, including reduced tool life, poor surface finish, and dimensional inaccuracy. Coolant systems must be appropriately selected and maintained to work effectively.

In conclusion, machining is a complex process that requires a comprehensive understanding of the variables that affect speeds and feeds, surface finishing, and common mistakes that lead to surface defects. By adopting a systematic and precise approach, manufacturing engineers can optimize their machining parameters, select the right tools, and avoid costly mistakes.

Tapping Threads in Steel

Introduction:

Tapping threads in steel is an essential process for manufacturing, repair, and maintenance projects that require screw connections. This comprehensive guide aims to provide a thorough understanding of the different types of threads, the critical elements of tap geometry, and the factors to consider when selecting the right tap for a job. Additionally, we will cover best practices for tap usage and common troubleshooting issues.

Understanding Tap Geometry and Thread Types:

The first step in tapping threads in steel is understanding the various types of lines available. The two most common types are metric threads and unified threads. Metric threads are measured in millimeters and are commonly used in Europe and Asia. Cooperative lines are measured in inches and are used in North America.

Tap geometry is another essential factor to consider when tapping threads in steel. The four critical elements of tap geometry are:

Flute: the spiral grooves on the tap that help remove chips from the hole.

Chamfer: the taper at the end of the fixture that guides the tap into the hole.

Thread Lead: the distance a tap advances in one turn.

Thread Profile: the shape of the threads on the tap, either V-shaped or U-shaped.

Choosing the Right Tap for the Job:

Selecting the right tap for the job depends on various factors, such as the type of steel used, the finished product’s intended use, and the desired thread tolerance.

Several taps are available, including hand, spiral point, spiral flute, and straight flute. Hand taps are used for manual operations, while machine taps are designed for use with power tools.

Best Practices for Tapping Threads in Steel:

Finally, let’s discuss some best practices for tapping holes in steel. These practices include correctly installing and maintaining the tap, managing chip buildup, and troubleshooting common issues such as broken taps and damaged threads.

When tapping holes in steel, it is essential to ensure that the tap is adequately lubricated and that chips are cleaned regularly. To prevent broken faucets, avoid exerting excessive force and ensure the fixture is correctly aligned with the hole.

Conclusion:

In summary, tapping threads in steel requires understanding tap geometry and thread types and the factors that should be considered when selecting the right tap for the job. By following best practices, you can ensure that your tapping operation runs smoothly and efficiently.

Applications and Industries Using CNC Machining Steel

CNC machining, also known as computer numerical control machining, is a manufacturing process that utilizes advanced software programs to control machinery and accurately produce parts and components. CNC machining is widely used across various industries due to its precision, speed, and ability to produce complex geometries. This report will focus on the applications and initiatives that benefit from CNC machining steel.

Automotive Industry

The automotive industry has been one of the earliest adopters of CNC machining technology. CNC machining is crucial in manufacturing automotive parts such as engine cylinders, transmission casings, suspension components, and braking systems. Details produced through CNC machining are highly accurate and have precise tolerances, leading to improved performance and durability of the vehicle. CNC machining has also reduced the production time of these components, leading to increased efficiency and cost-effectiveness.

Aerospace Industry

The aerospace industry requires precision and accuracy in its manufacturing processes due to air travel’s high risks. CNC machining is vital in producing aerospace components such as turbine blades, jet engine parts, and aircraft frames. These components require high durability, accuracy, and resistance to extreme temperatures and pressures. CNC machining has improved the precision and accuracy of these components, resulting in safer and more reliable aircraft.

Precision Engineering Industry

The precision engineering industry is centered around producing small, complex parts with tight tolerances. CNC machining is a perfect fit for this industry, as it can consistently make these parts with high accuracy. Examples of products manufactured through CNC machining in the precision engineering industry include gears, bearings, and sealing components.

Medical Device Manufacturing Industry

Medical device manufacturing relies heavily on CNC machining to produce surgical instruments, prosthetics, and implants. These products require extreme precision and accuracy to ensure the safety and well-being of the patient. CNC machining has facilitated the manufacturing of these products to exact specifications while guaranteeing high repeatability.

Construction and Infrastructure Industry

CNC machining has a limited role in the construction and infrastructure industry due to its reliance on heavy machinery and materials such as concrete and asphalt. However, CNC machining produces steel components such as beams and trusses to construct large structures. CNC machining in the building and infrastructure industry has improved these components’ accuracy and tolerances, increasing safety and longevity.

Advantages of Using CNC Machining in Steel Production

The advantages of using CNC machining for steel production are manifold. Firstly, CNC machining allows for highly accurate, repeatable, and consistent components presentation, improving performance, safety, and reliability. Furthermore, CNC machining enables the production of complex geometries that would be difficult or impossible to achieve through traditional machining methods. Finally, CNC machining has significantly reduced production lead times, increasing efficiency and cost-effectiveness.

Future of CNC Machining in Steel-based Products

As technology advances, the future of CNC machining in steel-based products looks bright. Using machine learning algorithms is expected to improve the accuracy and efficiency of CNC machining significantly. Additionally, multi-axis CNC machines are expected to increase, allowing for the production of even more complex geometries. Finally, 3D printing technology has the potential to disrupt the manufacturing industry, resulting in the creation of parts and components that were previously impossible to produce using traditional methods.

In Conclusion

CNC machining has revolutionized the manufacturing industry with its precise, consistent, and efficient production of parts and components of various shapes and sizes. CNC machining is widespread across multiple industries, including the automotive, aerospace, precision engineering, medical device manufacturing, and construction and infrastructure industries. The advantages of CNC machining in steel production include improved performance and durability of components, increased efficiency and cost-effectiveness, and the ability to produce complex geometries. The future of CNC machining in steel-based products looks promising, with technological advances expected to improve the accuracy and efficiency of the process.

Post-Machining Processes for Steel

As an industrial engineer, it is crucial to understand the Importance of post-machining processes for steel products. These processes involve several steps that contribute to producing high-quality steel machined parts. This guide will discuss the different post-machining strategies for producing high-quality steel machined parts.

Deburring and Polishing

Deburring and polishing are crucial post-machining processes for steel products. These processes involve removing any rough edges or burrs that may occur during the machining process. The process is typically achieved using abrasive materials like sandpaper or polishing wheels. However, it is essential to ensure that the process is done correctly, as it can impact the overall quality and accuracy of the machined part. Common issues with deburring and polishing include over-polishing, which can lead to a loss of accuracy, and under-polishing, which can result in rough edges. To address these issues, it is necessary to use the right tools and materials and perform the process carefully.

Heat Treatment for Steel Machining

Heat treatment is another critical post-machining process for steel. This process involves altering the physical properties of the steel product by exposing it to specific temperature conditions. The heat treatment process can enhance the steel’s machinability, durability, and strength. Different types of heat treatment methods exist, such as annealing, quenching, and tempering. The heat treatment method selection depends on the steel’s desired properties. The process can typically take several hours, depending on the size and complexity of the part. Common issues with heat treatment include warping, cracking, or distortion of the region. These issues can be addressed using the correct heat treatment method, ensuring the right temperature and time, and proper cooling techniques.

Surface Coating and Plating

Surface coating and plating are post-machining processes necessary for certain steel products. These processes involve applying a protective layer to the surface of the machined part to enhance its functional properties. Several types of surface coatings and platings exist, such as electroplating, anodizing, and powder coating. Each coating has unique benefits and is selected based on the specific application requirements. For instance, electroplating can improve the corrosion resistance of the steel, while powder coating can provide a durable and attractive finish. These processes can significantly enhance the performance and appearance of the machined parts.

QA and Quality Control Processes

Quality assurance and control are critical processes in producing high-quality steel machined parts. These processes involve multiple stages of inspection, testing, and verification to ensure that the claim meets the required specifications and standards. The different locations of quality control typically include inspection of raw materials, in-process testing, and final inspection. Testing machined parts for quality includes non-destructive testing, dimensional inspection, and metallurgical analysis. It is essential to ensure that these processes are followed rigorously to produce machined parts that meet the required quality standards.

Shipping and Packaging for Steel Machined Parts

Shipping and packaging are the final stages of post-machining processes for steel products. These processes ensure that the machined parts are appropriately packaged and protected during transportation to the customer. Using the suitable packaging materials, such as bubble wrap or foam inserts, is crucial to prevent damage to the parts during transit. The packaging should also include appropriate labeling and documentation to ensure the customer receives the correct position.

In conclusion, post-machining processes are crucial to producing high-quality steel machined parts. As an industrial engineer, following these processes rigorously and addressing any issues is essential. By doing so, we can produce parts that meet the required quality standards and exceed customer expectations.