TOP die casting manufacturer -ETCN offers cost-effective and breakthrough products for the latest technologies.

die casting

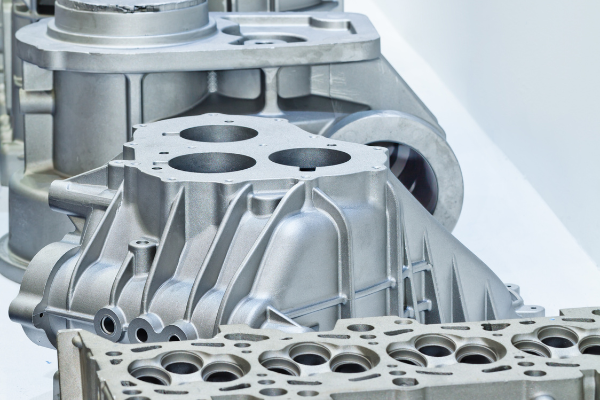

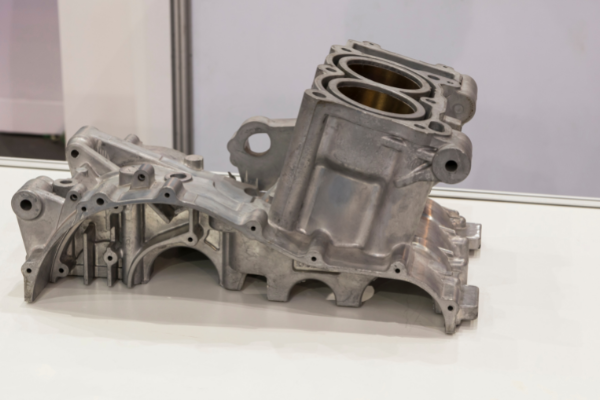

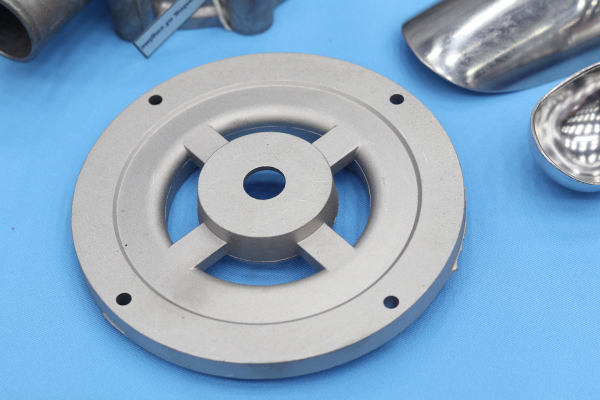

Die casting is a manufacturing process used to create objects from metal by pressing the molten metal into a die.

Die casting is one of the most versatile manufacturing processes because it can create a wide variety of objects, including parts for cars, aircraft, tools, and medical equipment. Die casting is also used to create difficult or impossible products to make any other way.

There are several die castings, including investment casting, sand casting, and lost-wax casting.

die casting process

The die casting process comes in two typesㅡwhich are hot chamber and cold chamber dies casting processes.

hot chamber die casting

Hot chamber dies casting is a process of manufacturing parts by using a heated die that contains the part to be produced. The molten metal is then forced into the die, where it solidifies and is ejected from the die. This process is often used to create parts that require stability and accuracy, such as engine parts or medical devices.

The benefits of hot chamber die casting are that it is fast and efficient. Parts can be created quickly, which is helpful when you need a custom part quickly. Additionally, the process can create parts with intricate details that would be difficult or impossible to achieve using other methods.

One downside of hot chamber die casting is that it can be difficult to produce accurate results. Because the process is so quick, mistakes can easily be made. If you are looking for precision in your design, cold chamber dies casting may be a better option.

cold chamber dies casting

The cold chamber dies casting processes are extensively used in manufacturing high-quality parts. The process is a very efficient way to create parts that are very smooth and free from imperfections.

The process involves using a die, which is then placed in a chamber kept at a very low temperature. This allows the die to create extremely accurate copies of the desired part without any chance of damaging the part of the tooling used in the process.

The main benefits of using the cold chamber die casting process include:

– Extremely high degree of accuracy

– Zero damage to parts or tooling

– Very quick turnaround times

high pressure die casting

High pressure dies casting is a process of manufacturing parts by forcing molten metal into the Die to create a part. The high pressure forces the metal into the Die quickly and evenly, creating a precise and durable part.

Advantages of high-pressure die casting include:

– Precise and durable parts: High-pressure die casting produces extremely precise and durable parts. This is because the metal is forced into the Die quickly and evenly, making for a more consistent piece.

– Reduced costs: Because high-pressure die casting is a process that uses less material than other manufacturing methods, it can lead to reduced costs overall. Additionally, due to its precision, high-pressure die casting often results in fewer defects in the final product.

– Reduced production time: High-pressure die casting can speed up production time considerably compared to other manufacturing methods. This is because the Die can be created quickly and with little effort, allowing parts to be manufactured more quickly.

low pressure die casting

Low pressure dies casting is a type of die casting where the pressure inside the die is kept at a low level to reduce the heat generated. This results in a higher quality product because less material is required to create a replica.

The automotive industry often uses the technique to produce small parts with high qualities. In this process, the die is slowly squeezed by a hydraulic press, which creates a consistent and uniform pressure on the part. This results in a more consistent cast and less porosity and distortion.

Advantages of ETCN’s Die Casting Services

ETCN is a world-class die casting company that offers a wide range of services, including die casting, forging, and machining. The company has a long history of excellence in the field, and its talented employees are dedicated to providing the highest quality products and services possible.

Some of the advantages of using ETCN’s die casting services include:

– Excellent quality products: ETCN’s die castings are some of the most authentic and quality products on the market. They are perfect for applications that require high tolerances and precision.

– Fast turnaround: ETCN can quickly produce your needed product with a quick turnaround time. This allows you to keep your business moving forward at a rapid pace.

– Comprehensive services: ETCN offers a wide range of services, including forging and machining, making it one of the most versatile companies in the die casting industry.

If you are looking for an outstanding die casting company that can provide you with quality products and fast turnaround times, look no further than ETCN.

Die Casting FAQs

Frequently Asked Questions.

Which metals are used in die casting?

Die casting is a process used to create metal objects from a liquid metal. The most common metals used in die casting are copper, bronze, and aluminum.

What are cast alloys used for?

Cast alloys are used in a variety of industrial and technological applications due to their high strength-to-weight ratios and corrosion resistance. Some common cast alloys used in manufacturing include iron, steel, aluminum, and bronze. Cast alloys are often found in applications where they resist wear or corrosion such as bridges, pipelines, and aircraft parts.

what is aluminum die cast?

Aluminum die cast is a manufacturing process in which an aluminum alloy is formed into a desired shape using die casting. This can be used to create products such as parts for automobiles, aircraft, and even electronic devices.

Die casting uses high pressure and temperatures to force the alloy into the desired shape. This process can create very detailed parts that are able to withstand a great deal of wear and tear. Because of this, aluminum die cast is often used in high-end products.

What is a die casting machine?

A die casting machine is a device that is used to create objects from a molten metal. The machine uses pressure and temperature to create the required moulds. Die casting is a very versatile process and can be used to create a wide range of objects, including car parts, toys, and jewellery.

How do you improve surface finish in casting?

There are many ways to improve the surface finish of casting. One common approach is to use a sanding disk. This disk has hundreds, sometimes thousands, of tiny holes that allow it to easily achieve a smooth finish.

Another way to improve the surface finish is to use a polishing compound. This compound removes the scratches and blemishes from the metal, resulting in a smoother finish.

Both of these methods require some experience and some experimentation to find the right combination that produces the best results. However, by using these techniques, you can significantly improve the overall appearance of your casts.

Which of these metals is commonly die-cast?

All three metals are commonly die-cast. They are aluminum, copper, and zinc.

What is parting line in die casting?

A parting line is a line on the die that separates the body part from the cavity. This line is important because it is where the die begins to create the shape of the object.

What is the melting point for cast aluminum?

The melting point for cast aluminum is 1,260 degrees Fahrenheit.

What is molten metal in casting?

Molten metal is the liquid form of metal that is used in casting. It is poured into a mold and set to cool, creating a final product.

What is a die in metal casting?

A die is a tool used in metal casting. It is a smooth, round object that is used to create patterns on the castings by pressing them down with a sharp edge.

Which casting process produces a thin wall casting?

There are many casting processes that can produce thin wall casting. One of the most common is sand casting. This process uses a sand mold to create the desired shape of the part. The molten metal is then poured into the sand mold, and it cools and hardens around the part. This process produces thin wall castings because the metal is not thickly deposited throughout the casting. Instead, it is concentrated in small areas near the surface.

What is multi-cavity molding?

Multi-cavity molding is a manufacturing process that creates plastic objects by injecting a liquid plastic material into a set of molds. The molds are then heated to the correct temperature and the plastic is injected into the molds, forcing it out through the various cavities. This process can create a wide variety of objects, from small plastic parts to complex objects with multiple cavities. Multi-cavity Molding is an efficient way to produce large numbers of custom parts quickly and at a low cost.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.