Brass C360

Discover everything you need to know about Brass C360! Visit ETCN for comprehensive information and find out how it could benefit your next project.

Details of Brass C360

| Property | Value |

|---|---|

| Alternative Names | Free-cutting brass, CZ360, C36000 |

| Density | 8.53 g/cm3 |

| Melting Point | 890°C |

| Thermal Conductivity | 109 W/(m*K) |

| Electrical Conductivity | 28.6 MS/m |

| Young's Modulus | 97 GPa |

| Yield Strength | 290 MPa |

| Tensile Strength | 580 MPa |

| Elongation | 35% |

| Hardness (Brinell) | 100-140 HB |

| Machinability | Excellent |

| Post Treatments | Annealing, cold working, hot working |

| Common Applications | Fasteners, valve stems, gears, bushings, electrical components, plumbing components, musical instruments |

Blogs related to CNC Machining Brass

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Brass C360: Frequently Asked Question

• Brass C360 is a popular brass alloy that combines high machinability and lead content for excellent mechanical properties.

• It is ductile and malleable, making it ideal for complex shapes and heat transfer applications such as radiator cores and heat exchangers.

• Its strength-to-weight ratio makes it a great material for fittings, valves, screws, and other hardware components.

• This alloy is also resistant to corrosion and a good electrical conductor, making it suitable for electrical components.

• It is used in many industrial applications due to its unique combination of excellent machinability, high thermal conductivity, corrosion resistance, and strength.

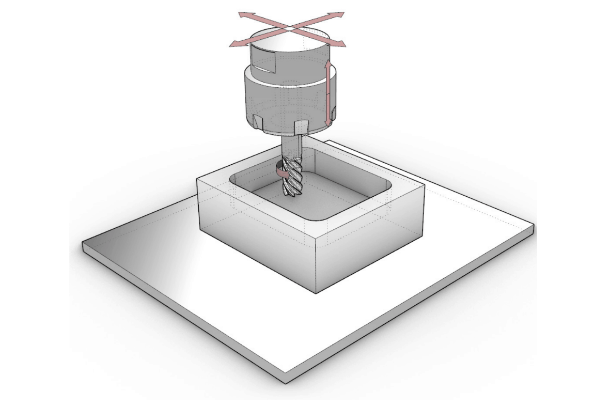

• Proper machining techniques should be utilized to maintain Brass C360’s mechanical properties, such as using coolant and lubricant to cut effectively.

• BrassC260, also known as Cartridge Brass, is composed of 70% copper and 30% zinc, making it highly corrosion-resistant and easy to work with. It is popularly used in the production of ammunition casings.

• BrassC360, or Free Machining Brass, contains 61.5% copper, 35.5% zinc, and 3% lead. This composition makes it ideal for CNC machining but unsuitable for drinking water or food equipment applications due to its lead content.

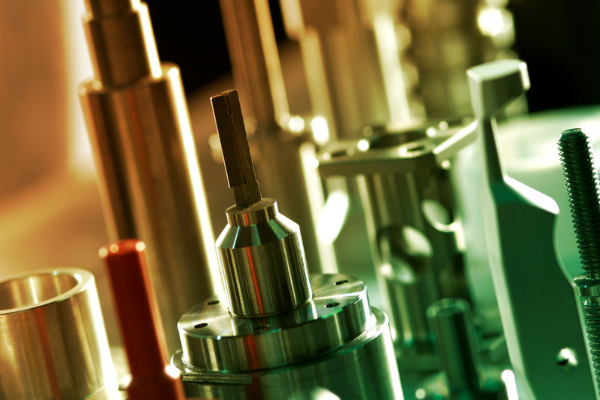

•BrassC360, also known as leaded brass, is frequently used for its excellent machinability, making it ideal for applications such as screw, nut, and bolt production.

•It is also a popular choice in the manufacturing of electrical components, such as connectors and sockets, due to its conductive properties.

•Additionally, brass C360 is used for decorative purposes, such as in the production of ornamental pieces, architectural and furniture trim, and musical instruments due to its visually appealing color and polish.

• Brass C360 is a popular choice for manufacturers and wholesalers due to its superior characteristics.

• One of the most significant advantages is its ease of machining, making it easy to process into desired shapes and sizes.

• It also boasts high strength, excellent thermal conductivity, and good corrosion resistance, making it ideal for use in various industrial applications.

• Brass C360 is versatile and can be employed in various forms, such as bars, rods, sheets, and pipes.

• The raw material is widely available, cost-effective, and can be recycled, making it an ideal choice for manufacturers who need to maintain low production costs.

• These favorable traits make Brass C360 a popular choice for those looking for a high-quality, cost-effective, and easily recyclable material for their products.

• Brass C360 is highly resistant to extreme temperatures and corrosive environments, making it a dependable choice for use in industries with challenging conditions.

• Its high melting point and corrosion resistance render it suitable for operations under adverse conditions such as marine, oil & gas, or aerospace applications.

• The mechanical properties of Brass C360 remain consistent at both low and high temperatures, making it ideal for precision operations that demand stability.

• Brass C360 can be plated or coated for additional protection. It is a popular choice of material for electroplating or coating because of its excellent ability to conduct electricity.

• Before plating or coating, it is important to make sure the brass is clean from contaminants such as oil, grease, or metal burrs.

• Various cleaning methods such as solvent cleaning, alkaline cleaning, or acid cleaning, can be used depending on the type of coating or plating being applied.

• Brass C360, also known as free-cutting brass, contains lead to make it easier to cut and machine, resulting in improved chip control, better thread rolling capabilities, and higher cutting speeds.

• Brass C360 offers better corrosion resistance, thermal conductivity, and electrical conductivity than other brass alloys.

• Though its lead content makes it suitable for a variety of applications, extra care may be necessary when handling the material to avoid lead exposure risks.