sheet metal fabrication

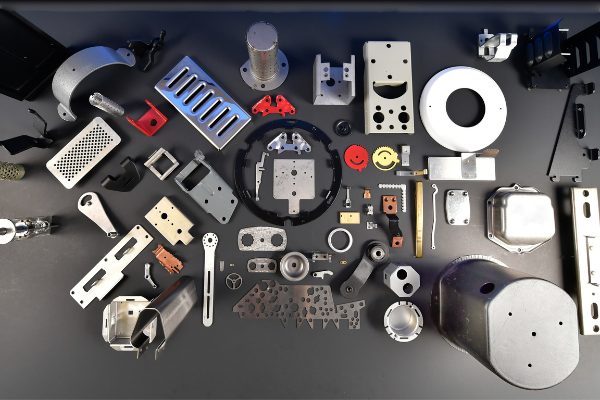

ETCN is a sheet metal fabrication company that provides a wide range of services, including welding, cutting, forming, bending, and more.

Sheet Metal Fabrication Services in China

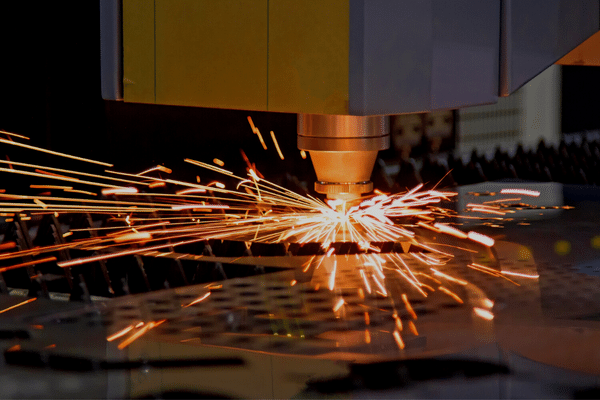

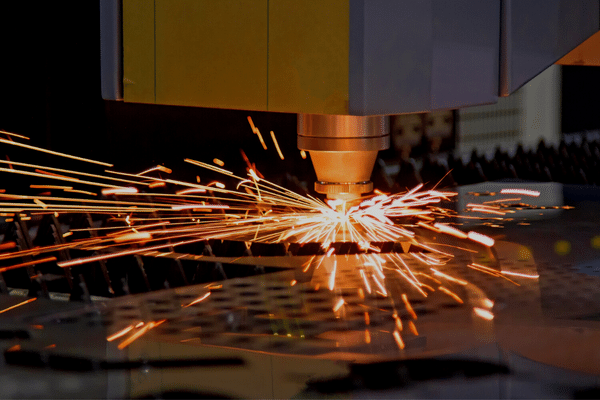

Sheet metal is a process for changing the dimensions of sheets of metal. These sheets can be cut, punched, riveted, and more for various results. The basic operation with sheet metals includes shearing, punching and cutting, laser cutting, and more using different machines.

ETCN is an experienced, custom metal fabricator providing metal fabrication services like new sheet metal machine frames, stainless steel metal fabrication, and titanium metal fabrication. we also provide services:Welding service 、Sheet Metal Bending、, sheet metal cutting、, CNC Punching, 、Sheet Metal Bending、CNC Metal Spinning

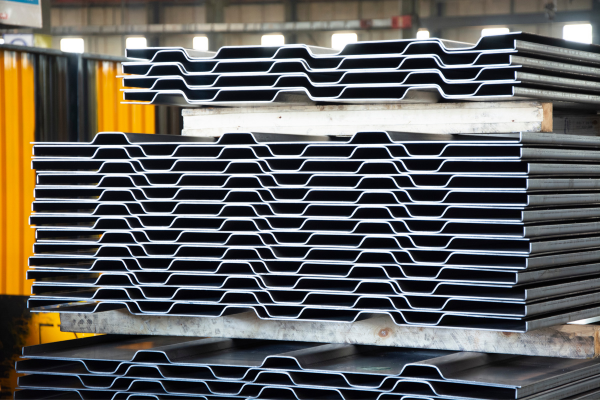

custom sheet metal

ETCN offers true quality at affordable prices. Sheet metal cutting service provided by long-time experts with years of experience in the industry.

Do you need new custom parts? ETCN can bend your metal to any shape or size. Sheet Metal Bending service offered

Industrial CNC punching service from china! ETCN is the most trusted and largest producer of high quality CNC punching.

Industrial CNC punching service from china! ETCN is the most trusted and largest producer of high quality CNC punching.

ETCN provides a full service welding service from China. We cover everything from standard fabrication to aluminum casting and more, with flexible project management methods to help you focus on your work.

What is sheet metal fabrication?

Sheet metal fabrication is the process of creating parts from thin sheets of metal by welding them together. The process can be broken down into three main steps: fabrication, assembly, and finishing.

The fabrication step is where the metal is cut into the desired shape and size. This can be done with a variety of tools, including a CNC machine or a manual welder. The assembly step is where the parts are welded together and then finished. This step can involve a lot of different techniques, including welding, brazing, and soldering. The finishing step involves polishing, coating, and sealing the metal to protect it from the environment.

sheet metal fabrication process

The metalworking process begins with a design or drawing that is created in a CAD program. The CAD file is then imported into a sheet metal fabrication program where the dimensions of the metal are determined. The shape and size of the metal object is then transferred to the metal sheet, which is then cut to fit. After the metal sheet is cut, it is then cleaned and prepared for welding. Welding techniques are then used to join the individual pieces of metal together, creating the final product.

The equipment used in sheet metal fabrication

When it comes to sheet metal fabrication, you’ll need a variety of tools and equipment. In this ultimate guide, we’ll cover the most common tools and equipment used in the trade.

Sheet metal fabrication is a complex process that requires accurate measurements and precise cuts. To get the most out of your project, make sure you have the right tools for the job. Here are some of the most commonly used tools in sheet metal fabrication:

1) Measuring tape: To ensure accurate cuts, use a measuring tape to measure the dimensions of your project.

2) Saws: A saw is essential for cutting metal sheets into desired shapes.

3) Drill: To create holes in metal sheets, use a drill.

4) Hammer: Use a hammer to tap holes into metal sheets.

5) Jigsaws: A jigsaw is perfect for cutting detailed pieces out of metal.

The benefits of sheet metal fabrication

Sheet metal fabrication is a great way to create custom products quickly and easily. Here are some of the benefits of this process:

-Sheet metal fabrication can create custom products quickly and easily.

-Sheet metal fabrication is a low-cost option for creating customized products.

-Sheet metal fabrication can create products with a high level of precision.

The costs of sheet metal fabrication

There is no one-size-fits-all answer regarding the cost of sheet metal fabrication, as the price will vary depending on the specific project and manufacturing methods used. However, some general costs include materials and labor costs, overhead, and factory overhead.

Materials: The most expensive component of sheet metal fabrication is likely the metal itself. This ranges from high-grade steel alloys to specialty metals like titanium that are difficult or impossible to find elsewhere. In addition, many materials must be cut, shaped, and welded by hand, which can add to high costs.

Labor: Although not always a cost driver, labor can account for a substantial portion of the total cost of a project. The skilled workers required for sheet metal fabrication often command high salaries and benefits, which can considerably increase the project’s overall cost. Additionally, many factories require long hours and weekends off to meet production deadlines.

Overhead: Manufacturing costs associated with sheet metal fabrication often include facilities and equipment rental fees, insurance premiums, and profit margins on supplies and equipment.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.