Brass C260

Discover the benefits of Brass C260. Check out ETCN for comprehensive information and technical data on this versatile material.

Details of Brass C260

| Property | Value |

|---|---|

| Alternative Names | Cartridge Brass, 70/30 Brass |

| Density (g/cm³) | 8.53 |

| Melting Point (°C) | 900-940 |

| Yield Strength (MPa) | 250 |

| Tensile Strength (MPa) | 450 |

| Elongation at Break (%) | 30 |

| Hardness (Brinell) | 65-95 |

| Electrical Conductivity (% IACS) | 27-30 |

| Thermal Conductivity (W/m·K) | 120 |

| Corrosion Resistance | Excellent |

| Post Treatments | Annealing, cold working, brazing, soldering |

| Common Applications | Plumbing fittings, valves, components for musical instruments, decorative items, ammunition casings |

Blogs related to CNC Machining Brass

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Brass C260: Frequently Asked Question

•Brass C260 is a copper alloy made up of copper and zinc.

• This gives it a bright yellow color and improved strength compared to other alloys.

•It also offers excellent electrical conductivity and good machinability and formability, making it suitable for many applications, including electrical contacts and fasteners.

•Brass C260 can also provide good corrosion resistance in most environments and is generally easier to work with than pure copper or brass alloys with higher zinc content.

1. Brass C260 is commonly used in the aerospace, automotive, and electrical industries due to its strength, electrical conductivity, and corrosion resistance.

2. It’s often used in electrical components, connectors, screws, and other fasteners, as well as control panels and industrial machinery. 3. It is also used in architectural applications such as door fixtures, door knobs, handles, etc.

4. In addition to this, brass C260 has many uses in the artistic/jewelry industry due to its attractive color.

•Brass C260 can be used for outdoor applications.

•It has excellent resistance to corrosion in most environments, so it is a suitable choice for outdoor fixtures and components.

•However, it is important to note that in harsh conditions with high humidity or saltwater exposure, Brass C260 may begin to corrode over time.

• Brass C260 is a durable, strong brass alloy that offers superior strength, electrical conductivity, and corrosion resistance compared to other types of brass alloys.

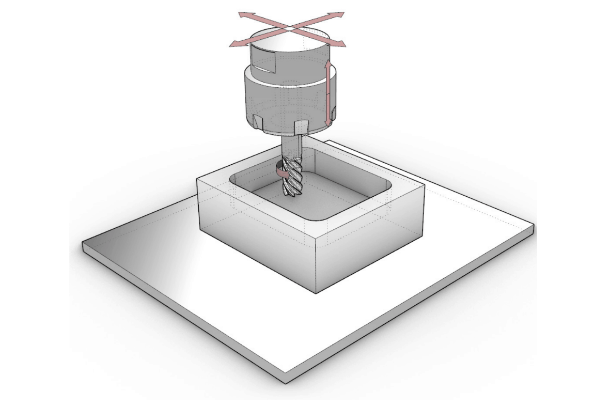

• It has excellent machinability and formability properties, making it suitable for the manufacturing industry for complex operations and intricate shaping.

• With its superior corrosion resistance, Brass C260 can also be used in outdoor applications with consideration for extreme conditions.

• This alloy is ideal for a variety of industrial applications including architectural designs and ornamental trim, plumbing fixtures and fasteners, air conditioning components, wiring systems, and electronic connectors.

• Brass C260 is an eco-friendly solution as it is lead-free and requires less energy input during manufacturing.

• Moreover, it’s fully recyclable, meaning that it can be remelted and reused repeatedly without losing its original characteristics.

•Because of its excellent performance and durability, Brass C260 reduces the need for frequent replacements, thereby reducing the overall environmental footprint of the manufacturing process.

• Brass C260 is a unique and versatile alloy with superior electrical conductivity and corrosion resistance, making it ideal for metalworking operations.

• Its composition of 59% copper, 1.7% lead, and 39.3% zinc allows for stronger than-usual strength to enable complex machining processes and increased durability.

• Varying ratios of these alloys can affect product performance according to their intended application, so it’s important to consider the ratio when specifying an alloy.

• The superior mechanical properties of Brass C260 allow for applications in various manufacturing industries, from precise machining operations to intricate forming.

• Its excellent corrosion resistance makes this alloy suitable for use in outdoor fixtures or components exposed to harsh conditions such as saltwater or high humidity.