Precision CNC Bored Parts Manufacturer in China

ETCN is a manufacturer of precision boring parts that offer high quality, low cost, quick delivery, and reliable service from experienced manufacturing professionals.

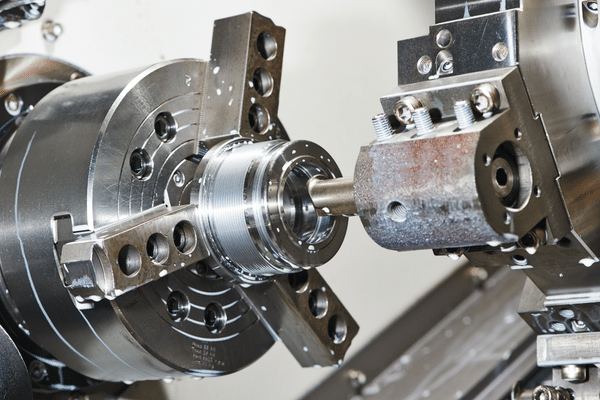

Precision boring processing parts

CNC Boring Service

CNC boring is used for the shaft sleeve of large equipment, and the tolerance of the bearing position is plus-0.03mm. After welding accessories, use CNC horizontal boring and milling equipment to process both sides with a concentricity of plus-0.05mm.

If you’re looking for a way to increase production efficiency and decrease manufacturing costs, look no further than CNC boring services. A CNC boring service can help you produce complex parts and assemblies quickly and accurately without needing expensive tooling or machining. With a CNC boring machine, you can easily create holes, slots, and other custom shapes in metal parts using precise, repeatable movements.

Here’s a quick overview of what a CNC boring service can do for you:

– Saving time and money on manufacturing: A CNC boring machine can help you quickly create complex parts and assemblies without needing expensive tooling or machining. This is particularly important when producing high-volume products or components with specific requirements.

– Precise, repeatable movements: With a CNC boring machine, you can easily create holes, slots, and other custom shapes in metal parts using precise, repeatable movements. This means that your parts will be accurate and consistent in dimensions and shape.

– Reduced assembly time: A CNC boring machine can help reduce the time needed to assemble complex parts or assemblies. By automating certain steps of the manufacturing process.

welcome to our factory

CNC Boring

Welcome to our CNC Boring Service Factory. Here you can learn about the different types of bores we offer, what series of bores are used for your job, and meet our team and ask any questions you may have.

Advantages Of ETCN’s CNC Boring Services

When it comes to milling and turning, CNC boring services from ETCN are second to none. Here are some of the advantages of using our services:

1. Quick turnaround times: With our fast turnaround times, you can get your project completed quickly and on schedule.

2. High-quality cuts: Our experienced milling and turning personnel use the latest technology and equipment to produce high-quality cuts.

3. Superior accuracy: Our state-of-the-art equipment ensures that your cuts are accurate and precise.

If you’re looking for a reliable and professional CNC boring service, look no further than ETCN. We’ll provide you with quality results at a fair price

CNC Boring Capabilities

CNC horizontal milling and boring machine are suitable for machining large and medium-sized parts and box parts, rough and fine boring, milling, and other processes.

The worktable is equipped with a 4×90 ° optical positioning device, which can meet the requirements of large parts turning. The CNC horizontal milling and boring machine are suitable for the hole and plane processing of box parts with many processes, turning of a cylindrical surface, cutting of annular groove in the hole, tapping of male and an English screw thread with a tap, etc.

It also has the technological functions of the rectangular coordinate system, polar coordinate system, and contour processing of the CNC machine tool. Because the CNC horizontal milling and the boring machine have high rigidity and a closed-loop detection system, which can meet the requirements of rough and fine machining, the CNC horizontal milling and boring machine is a high-efficiency and precision general-purpose large-scale machining equipment.

Technical Parameters Of CNC Boring Service

The technical parameters of CNC boring service are widely used during the surface finish process with CNC boring machine.

| Machinery | 3 | |

|---|---|---|

| Material | Alloys Steel | Bronze Alloys |

| Aluminum Alloy | Stainless Steel | |

| Copper | Carbon Steel | |

| Brass | POM/PA | |

| Features | Deburring | Drilling |

| Tapping | Milling | |

| Threading | Boring | |

| Grinding | Knurling | |

| Maximum Dimensions | 6000mm*2000mm | |

| Inspection Capabilities | CMM | Projector |

| Imaging Measuring Instrument | Hardness | |

| Metallographic Microscope | Non-destructive Equipment | |

| Automatic Thread Inspection Equipment | ||

| Surface Finished | Zinc Plated | Sand Blasted |

| Nickel Plated | Blacking | |

| TD Coating | Phosphating | |

| Dacromet | Zinc-Nickel Plating | |

| Thread | UNF | UNC |

| NPT | SAE | |

| Metric | BSPP | |

| BSPT | JIS | |

| DIN | G | |

| R | ZG | |

| Certification | ISO9001-2008 | ISO/TS16949 |

Customized CNC Boring Parts

Authoritative Guide: CNC Boring

Frequently Asked Questions.

what is cnc boring machine?

cnc bored machines are the most flexible types of machines in cnc manufacturing. A cnc machine is a computer numerical control (cnc) mill, lathe or screw machine that uses computer-controlled automated machinery to perform various tasks. They’re also portable and can be moved and programmed easily.

how to put boring tools on a cnc lathe?

This is a common question that rig makers have. To put boring tools on a cnc lathe, we use the turret twist method.

It is essential to rotate the tool by hand before you insert it into the turning fixture to make sure you can still get it out.

Once the tool is inserted into the turning fixture, always keep your hand on the opposite side of where you are cutting so that you don’t hit your fingers with the tool as well.

boring machining

In boring machining, we adhere to all of the current US legislation and industry standards. Our teams follow all safety regulations from both the national and industry-specific level. We have staff available 24/7 and are available internationally, in other time zones, on weekends, and holidays. We are open six days a week and also offer outdoor work as well.

how does a horizontal boring machine work

The horizontal boring machine works by what is called a radial air drill. The machine’s teeth or cutting points are at the bottom, and the windings-circular part of the screw along with the body of the drill are raised on top. A long piece of steel bars serves as a guide for the circular part, allowing it to turn around in a circle.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.