TOP Stainless Steel Machined Parts supplier from china

ETCN supplies high-quality Stainless Steel Machined Parts, as well as promotional products for your business.

Home » Complete Guide to CNC Machining » Stainless Steel Machining

Top-Grade & Cost-Effective Stainless Steel Machined Parts – Stainless Steel Parts

top stainless steel parts manufacturers - ETCN

ETCN is a professional stainless steel parts manufacturer and exporter.

We have our own factory, with more than 20 years experience in this industry.

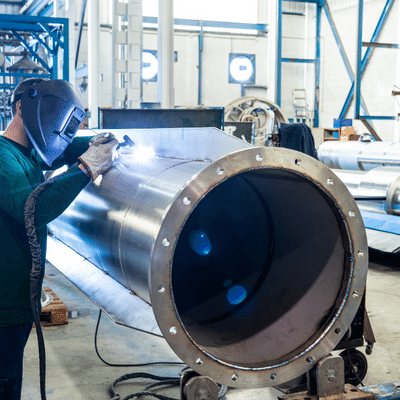

We can produce the stainless steel parts according to your drawings or samples. Our products are widely used in machines, welding equipment, automobile, instrumentation, medical device, food processing, and so on.

We can supply all kinds of stainless steel machined parts with high precision and good quality.

We have a wide range of standard products, such as stainless steel machined parts, sand casting parts, and die casting parts.

If you’re looking for a CNC machining supplier, then you’ve come to the right place.

what is stainless steel parts?

Stainless steel is a metal alloy that contains between 10.5% and 30% chromium. In addition, it also contains nickel, molybdenum, and other elements. Stainless steel is corrosion resistant, which means it doesn’t corrode or rust. It is used in many industries to make a variety of products such as cookware and surgical instruments.

Stainless steel parts are available in a variety of forms, including bar stock, plate stock, and tube stock. The most common form of stainless steel is 304-grade stainless steel, but there are many other grades of stainless steel that offer different features and benefits depending on the application.

benefit of stainless steel parts

The main benefit of using stainless steel parts over other metals is their durability and resistance to corrosion. Stainless steel can withstand extreme temperatures without losing its properties or becoming brittle; this makes it an excellent choice for use in high-temperature environments such as blast furnaces or nuclear reactors where other metals would be too soft or brittle to withstand the heat without cracking or breaking down over time.

CNC Stainless Steel Machining

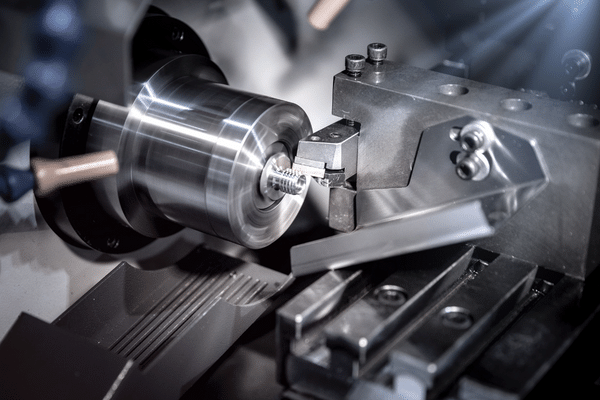

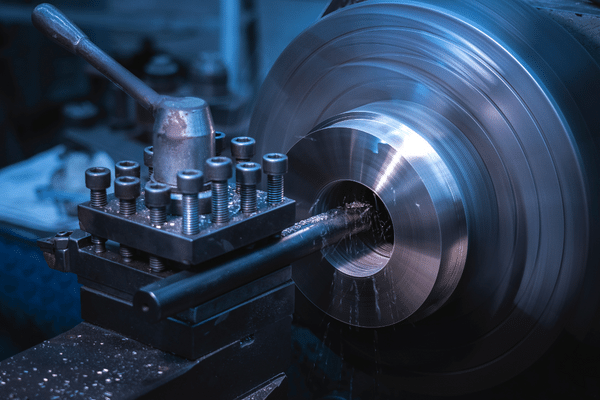

CNC stainless steel machining is a process that is used to make parts from metal. The process uses computer numerical control (CNC) to operate the machines, which are typically made of metal or plastic. A CNC machine can be programmed to cut, drill, and mill parts that are made of various materials.

CNC stainless steel machining involves cutting, drilling, and milling parts out of metal material such as stainless steel or aluminum. The process uses computer numerical control (CNC) to operate the machines, which are typically made of metal or plastic. A CNC machine can be programmed to cut, drill, and mill parts that are made of various materials.

Advantages of CNC Stainless Steel Machining

There are many advantages to using CNC stainless steel machining over manual processes. For example:

Precise Control – The software used by CNC machines allows for very precise control over the cutting process. This makes it possible to create products with extremely tight tolerances. This is particularly important when it comes to medical devices and other precision products where even small variations can have a significant impact on the final product’s performance or safety.

Faster Production – CNC machines allow you to increase your production rate without increasing your labor costs. This is possible because they use automated processes that require little direct human interaction or supervision (and therefore less training). These machines also allow you to work around the clock if necessary, which means fewer wasted hours due to downtime while workers take breaks or go home at night or on weekends

Specification of Our Stainless Steel CNC Machining Services

stainless steel materials

We have the ability to machine a wide range of stainless steel materials, including:

304/304L (UNS S30400/S30403)

316/316L (UNS S31600/S31603)

310 (UNS S31000)

321 (UNS S32100)

Surface Finishing

We offer a full range of surface finishing options including diamond turning and grinding, shot blast cleaning as well as mirror polishing. This helps us provide you with an excellent finish for your product.

Cleaning

Our cleaning methods include ultrasonic cleaning, chemical treatment and acid pickling for removing surface contamination before machining or welding operations.

Custom Colors

We offer a variety of standard colors including black, blue, red, green and yellow. We can also do custom colors for an additional charge.

CNC Machining Services

We offer machining services for all types of metals including stainless steel, aluminum, brass, and copper. We can also machine plastics, phenolic materials, and other composite materials.

Our CNC machining centers are all equipped with state-of-the-art equipment to provide high-quality machined parts and components. Our machining capabilities include:

Stainless Steel CNC Milling, Stainless Steel CNC Turning, Drilling Stainless Steel

custom stainless steel parts

Our machining capabilities range from simple to complex geometries, including but not limited to:

Custom stainless steel parts

Large diameter stainless steel parts

Turned or milled flanges, hubs, and machined flats

Precision machined collar shafts and bushings

Gears and shafts with specific tolerances or dimensions

Weldments with complex geometries