[lwptoc]

introduction

Introduction to Machining

Machining is a subtractive manufacturing process that involves cutting away material from a workpiece using a variety of specialized tools and techniques. It is a common method used across various industries, including automotive, aerospace, medical, and construction. Machining is used to create a variety of parts and components, from simple to complex, so it is essential to understand the basic machining techniques used to ensure successful parts production.

What is Machining?

Machining is a subtractive manufacturing process that involves cutting away material from a workpiece with the use of a variety of specialized tools and techniques. It is a common method used across various industries, including automotive, aerospace, medical, and construction. Machining is used to create a variety of parts and components, from simple to complex.

Overview of Machining Techniques

Several machining techniques are used to achieve a particular workpiece’s desired results. The three most common techniques for machining are milling, turning, and drilling.

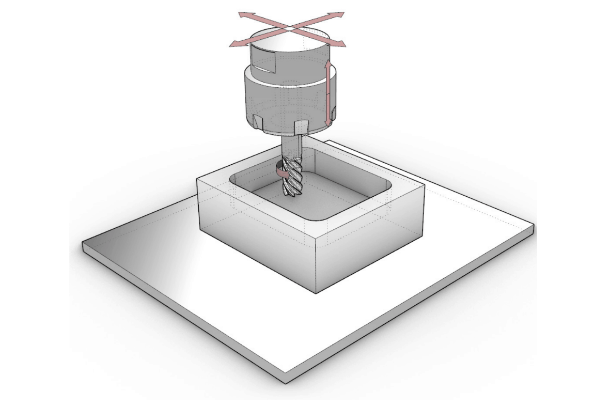

Milling: Milling is a machining process involving cutting material from a workpiece using a rotating cutting tool. This is done using various specialized tools, such as end mills, face mills, and form cutters. Milling is used to create various components, including gears, cams, and spindles.

Turning: Turning is a machining process that involves rotating a workpiece and cutting away material from the outside surface. This is done using various specialized tools, such as lathes and turning machines. Turning is used to create a variety of components, including shafts, pins, and bushings.

Drilling: Drilling is a machining process that involves cutting away material from a workpiece using a rotating drill bit. This is done using various specialized tools, such as twist and core drills. Drilling is used to create various components, including fasteners and threaded components.

These are the three most common machining techniques used in the manufacturing industry, but other techniques are also used. These include grinding, honing, and lapping, which is used to create components with high levels of accuracy.

Conclusion

Machining is an essential part of the manufacturing industry and is used across various industries. The three most common machining techniques are milling, turning, and drilling, but other techniques are also used. Understanding the different machining techniques is essential for successful parts production.

basic machining techniques

In machining, four basic techniques are used to shape, cut, or form metal and other materials. These techniques are turning, drilling, milling, and grinding. Each technique has its unique capabilities and can be used to create parts with different properties and uses. In this blog, we will discuss these techniques in more detail so you can understand their purpose and uses.

Turning is a machining process that creates cylindrical parts with a rotary cutting tool. This technique is used to shape, cut, bore, or face cylindrical parts, such as screws, bolts, and shafts. The cutting tool is rotated against the workpiece while the cutting tool is fed linearly. This machining technique is manual and can be done with a lathe or a milling machine.

Drilling is a machining process used to create and enlarge holes in parts. It is done with a drill bit, fed through the part, and rotated at high speed. This process creates and shapes holes for fasteners, such as screws and bolts, or creates ventilation holes. Drilling is usually done with a drill press or a milling machine.

Milling is a machining process used to create shapes and contours in parts. During this process, the workpiece is fed against a rotating cutting tool while the cutting tool is fed in a linear direction. Milling is used to create various shapes, such as slots, grooves, and threads, as well as to create curved surfaces. This technique manufactures gears, cams, and other complex parts.

Grinding is a machining process used to remove material from a workpiece. It is done with an abrasive wheel or belt fed against the workpiece. This process creates a smooth finish on the part and is often used to polish parts after they have been machined. Grinding can also be used to sharpen cutting tools or to create intricate shapes.

These four basic machining techniques are used in various industries, from automotive to aerospace, to create parts with specific properties and uses. Each technique has its unique capabilities and can create parts with different properties and uses. Understanding how these techniques work and what they are used for will help you better understand the machining process and how to create the parts you need for your project.

safety considerations

When it comes to machining, safety considerations are paramount. The use of personal protective equipment (PPE) and the implementation of workplace safety best practices must be taken into account to ensure the safety of everyone in the workplace.

The most important factor in machining is personal protective equipment (PPE). PPE provides a barrier between the individual and any potential hazards. Depending on the type of machining being done, the selection of PPE will vary. For example, safety goggles are necessary when working with drill presses, while hard hats may be needed when operating a saw. It is important to always check with your employer or safety regulations to ensure the appropriate PPE is being used.

Get the complete solution. ↓

In addition to using the appropriate PPE, several workplace safety best practices should be considered. These include maintaining a clean and orderly workspace, keeping all tools and materials in their proper place, and following any safety procedures that are in place. When lifting heavy objects, it is important to use proper lifting techniques to prevent injury.

It is important to be aware of the potential hazards associated with any machining. For example, some machines require cutting fluids, which can be hazardous if not handled properly. It is also important to know the potential for electric shock, as some machines may be powered by electricity. In addition, it is important to be aware of the potential for sparks and flying debris when operating a machine.

When it comes to the proper operation of a machine, several basic techniques should be taken into account. First and foremost, reading through the operator’s manual is important to understand how to operate the machine properly. It is also important to be aware of any safety features that may be in place on the machine, such as guards or emergency stop buttons. Finally, it is important to be aware of any potential hazards associated with the machine, such as flying debris or sparks.

Overall, safety considerations are key when it comes to machining. It is important to use the appropriate PPE and to follow workplace safety best practices to ensure the safety of everyone in the workplace. By being aware of the potential hazards associated with a machine and the basic techniques for proper operation, everyone can ensure that the machining process remains safe and productive.

conclusion

Conclusion: Summarizing the Benefits of Machining

Machining is an essential process in manufacturing and industrial operations. It is a fundamental activity that enables the creation of parts with precise shapes and sizes. In this blog, we have discussed the basic techniques of machining, the advantages, and the importance of choosing the right machining process for a particular job.

The most common machining techniques include turning, drilling, milling, and grinding. Turning creates cylindrical parts by removing material from a rotating workpiece. Drilling is used to creating holes of different shapes and sizes. Milling is a process of cutting, shaving, or shaping a material using a rotating cutter. Grinding is the process of finishing the surface of a part by removing material from the surface using an abrasive wheel.

The benefits of machining are numerous. Machining can produce parts with precise dimensions, shapes, and sizes. It also offers the accuracy and repeatability that other processes cannot provide. Furthermore, it can produce parts with a variety of materials.

Finally, choosing the right machining process for a particular job is important. This is because each process has its own set of advantages and disadvantages. Therefore, it is essential to consider the material, the desired shapes and sizes, and the desired accuracy before selecting a process.

To summarize, machining is an essential process in industrial operations and manufacturing. It can produce parts with precise dimensions, shapes, and sizes. It offers accuracy and repeatability that other processes cannot provide. Furthermore, it can be used on a variety of materials. However, choosing the right machining process for a particular job is important. This is because each process has its own set of advantages and disadvantages.