An Introduction to CNC Machining

CNC machining is a relatively new manufacturing technology that has revolutionized the way parts and components are made. It is an automated process that allows for precise control of the cutting and shaping of materials like metals, plastics, and composites for various applications. But what exactly is CNC machining and how can it be used? Let’s take a look.

What Is a CNC Machine?

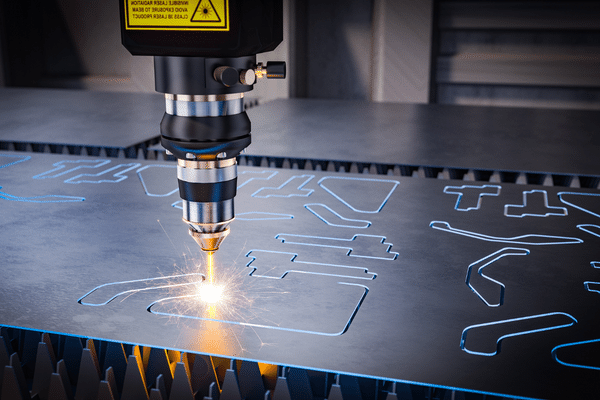

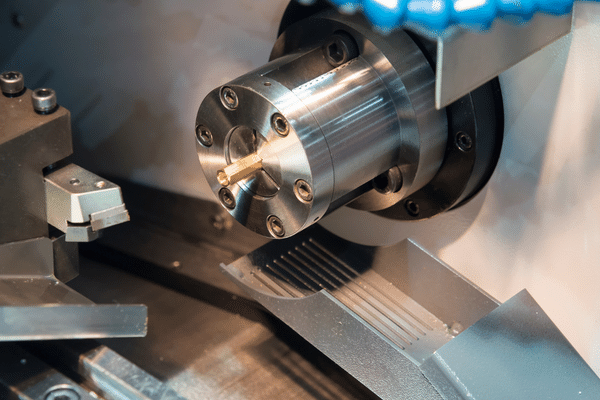

A CNC machine (Computer Numerical Control) is an advanced computer-controlled machine used in various industries to produce parts with extreme accuracy and efficiency. A CNC machine utilizes three main components: a software program, a control system, and a cutting tool. The software program contains instructions that tell the machine where to move the cutting tool, while the control system operates the mechanical movements of the cutting tool.

What Can a CNC Machine Be Used For?

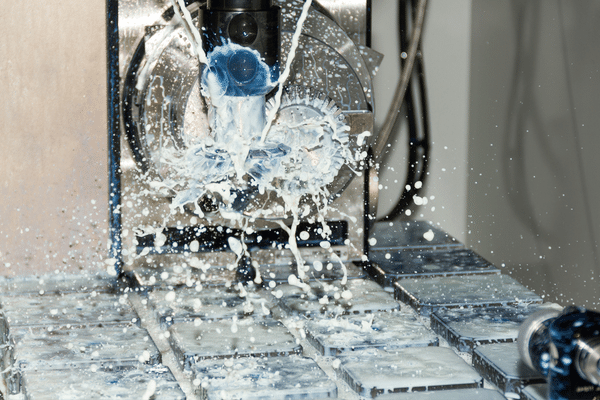

CNC machines are used in many industries, including aerospace, automotive, defense, medical device manufacturing, jewelry making, 3D printing, and more. They can be used for milling, drilling, turning, grinding, tapping threading, and other processes on various materials such as aluminum, brass steel plastic composites, etc. With its versatility and precision capabilities, it enables complex parts to be produced quickly from simple manual processes with just one setup.

The Benefits of Using CNC Machining

CNC machining offers numerous advantages over traditional manual labor operations. Automating production processes with accurate results every time will generate less waste from human error or misplacement of parts or tools during operation. This will save money by reducing costs associated with product rework or scrap material disposal costs. Additionally, due to its repeatability high precision results can be achieved every time you run your job which further reduces cost while increasing production speed thus increasing profit margins and customer satisfaction levels.

In conclusion, CNC machining is an ideal solution for anyone looking to increase their production speed while still maintaining quality precision results at all stages of production. Its versatility makes it suitable for use in many different industries with its ability to cut any material into any shape desired without sacrificing accuracy or consistency each time it’s run through production cycles. Investing in high-quality CNC machining can help your business save money by reducing scrap material disposal costs while increasing profits due to increased production speed and improved overall customer satisfaction.

Unlock the Benefits of CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process that automates the production of parts and components. This type of machining uses computer-controlled tools to produce high-precision parts from materials such as steel, aluminum, and plastic. Whether looking for one-off prototypes or large-scale production runs, CNC machining can help you achieve fast turnaround times with repeatable precision and accuracy. Let’s take a look at some of the benefits CNC machining has to offer.

Speed and Efficiency

CNC machines can operate with incredible speed and efficiency, often completing projects in hours instead of weeks. They also require minimal setup time, which means less downtime between jobs. Plus, since CNC machines are programmed to operate without human intervention, you don’t have to worry about operator fatigue or errors caused by manual operation. As a result, your turnaround time is much faster than with traditional machining methods.

Cost Savings

CNC machines can save you money in several ways. For starters, they require fewer tools than traditional machining methods since they use the same tool for multiple operations. This reduces tooling costs while increasing overall machine productivity. Additionally, because CNC machines are preprogrammed with exact specs and tolerances, they produce fewer scrap pieces than manual processes, which means lower material costs for you!

Accuracy and Quality

Due to their precise programming capabilities, CNC machines can produce parts with tight tolerances and consistent quality every single time. Manual processes cannot match this level of repeatability, and it’s one of the biggest advantages of using a CNC machine instead of manual labor for your projects. With a CNC machine, you know exactly what size part you’ll get every time—ensuring accuracy and quality control on even the most complex jobs.

Overall, investing in a CNC machine is an excellent way to increase productivity while reducing costs and ensuring consistent quality across all your projects. From fast turnaround times to precise accuracy and repeatable results, there are many benefits that come from using this type of machinery over traditional manual processes. Whether you’re looking for one-off prototypes or large-scale production runs, investing in a CNC machine could be just what your business needs to stay competitive in today’s market!

The Pros and Cons of Owning a CNC Machine

CNC machines are becoming increasingly popular for businesses that need to produce parts quickly, accurately, and efficiently. But before you invest in a CNC machine for your business, it’s important to understand the pros and cons of owning one. Let’s take a look at some of the factors that should be considered when deciding whether or not to purchase a CNC machine.

Cost & Maintenance of a CNC Machine

Cost is one of the most important factors to consider when investing in a CNC machine. The initial cost of purchasing a CNC can be quite high depending on the type of machine being purchased, so it’s important to do your research beforehand to understand your investment. In addition to the initial cost, you must also factor in regular maintenance costs to keep your machine running smoothly. This includes things like replacing worn-out parts, lubricating moving components, and more.

Reliance on Technology

Another factor to consider is that while CNC machines can help streamline production processes, they rely heavily on technology. This means that if something goes wrong with the computer system or software controlling the machine, it can cause major delays in production and increase expenses due to downtime. If you aren’t tech-savvy or don’t have someone who is knowledgeable about how these machines work, having access to a technician may be necessary to keep your machine running smoothly at all times.

Safety Considerations

Finally, safety is always an issue when working with any machinery, particularly with CNC machines due to their complexity and reliance on automated processes. It is essential that anyone using or working around these machines understands proper safety protocols such as wearing protective gear (e.g., gloves, goggles), avoiding lose clothing/jewelry near moving parts, and never reaching into moving parts without turning them off first. It is also important for businesses using CNC machines to provide adequate safety training for their employees prior to allowing them access to the equipment.

CNC machines offer many advantages over traditional manufacturing methods, but several drawbacks should be considered before investing in one for your business. Cost and maintenance expenses must be factored into any decision-making process, reliance on technology, and potential safety hazards associated with operating these machines properly. By weighing all these factors carefully before investing in a CNC machine, buyers can ensure they are getting the best value for their money while still safely and efficiently meeting their production needs.

Is CNC Machining the Right Choice for You?

When considering automating your production process, you may have come across the option of Computer Numerical Control (CNC) machining. CNC machining is a manufacturing process that uses computerized controls to operate machine tools such as lathes and mills. But how do you know if a CNC machine is right for you? Let’s take a look at some of the factors to consider when making this decision.

Costs of Ownership

The cost of purchasing a CNC machine is just one factor to consider; other costs are associated with ownership. These include ongoing maintenance, power requirements, and additional software or peripherals that may be needed. It’s important to factor in these costs when determining whether a CNC machine is the right choice for your business.

Production Volume

Another important factor to consider is the volume of production that you need from the CNC machine. If you require high-volume production, then investing in a CNC machine can be beneficial since it offers automation capabilities that can help increase production rates. However, if your needs are more modest, traditional manual machines may still suit your operation.

Expertise Required

Finally, it’s important to think about the level of expertise required to operate and maintain a CNC machine. They are complex pieces of equipment and require skilled personnel who are able to understand the complexities involved in programming and operating them correctly. Manual machines may still be suitable for your operation if you don’t have access to skilled personnel or don’t have time to train them.

When deciding whether or not a CNC machine is right for your business, it’s important to evaluate all aspects of ownership before making a purchase decision. Consider factors such as costs associated with ownership, production volume requirements, and expertise required by operators and staff before committing to a purchase.

In addition, it’s also important not to overlook other options available such as traditional manual machines which may still offer advantages depending on factors such as budget or availability of skilled personnel. Ultimately, by weighing all these factors carefully you should be able to make an informed decision about whether or not a CNC machine is right for your business needs.

How to Find Used CNC Machines for Sale

Purchasing a used CNC machine is an attractive option for those looking to get into the world of CNC machining. Used machines may be more affordable and still provide the quality and accuracy you need. Here are some tips on how to find used CNC machines for sale.

Research Online

Start your search by researching online. Look for reputable websites that specialize in selling used CNC machines, such as eBay or Craigslist. You’ll want to pay attention to the descriptions of each machine and check out any reviews or customer feedback if available. Also, make sure to read the terms and conditions before making a purchase. This will help you make sure you’re getting the best deal possible on a quality machine.

Visit Machinery Suppliers

Another great way to find used CNC machines is by visiting local machinery suppliers or industrial auctioneers specializing in selling and buying used equipment. These suppliers often have access to a wide selection of machines, allowing you to choose from both new and used models that fit your budget. Many suppliers also offer certification programs that guarantee that each machine has been inspected prior to being sold, ensuring that it meets industry standards and is safe for use in your facility.

Contact Manufacturers Directly

If you’re looking for a specific type of CNC machine but can’t find it through a supplier or online retailer, consider contacting the manufacturer directly. Many manufacturers offer discounts on older models or refurbished models which are still in excellent condition but may not be available in stores or online retailers anymore. You may get access to special deals that aren’t available anywhere else by contacting them directly. Additionally, some manufacturers may even offer financing options so you can spread out payments over time while still getting the machine you need at an affordable price point.

Whether you’re just starting out with CNC machining or simply looking for an upgrade without breaking the bank, there are plenty of ways to find quality used machines for sale at an affordable cost. Be sure to do your research before making any purchases and consider all your options – from researching online retailers like eBay and Craigslist, visiting local machinery suppliers or industrial auctioneers, or even reaching out directly to manufacturers – so that you can find the perfect machine without exceeding your budget!