What is a CNC Machine and What Can It Be Used For?

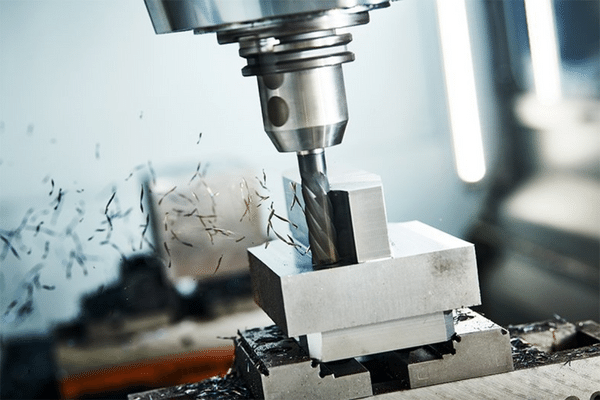

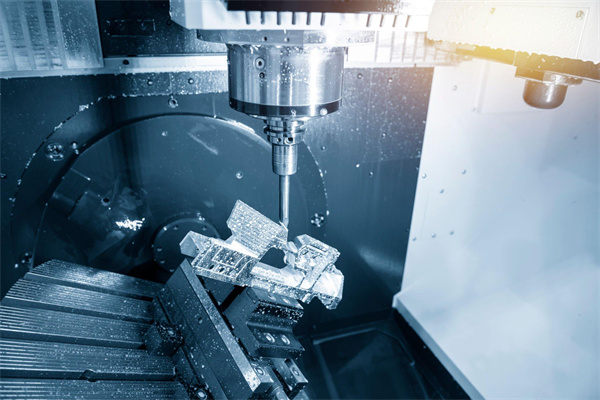

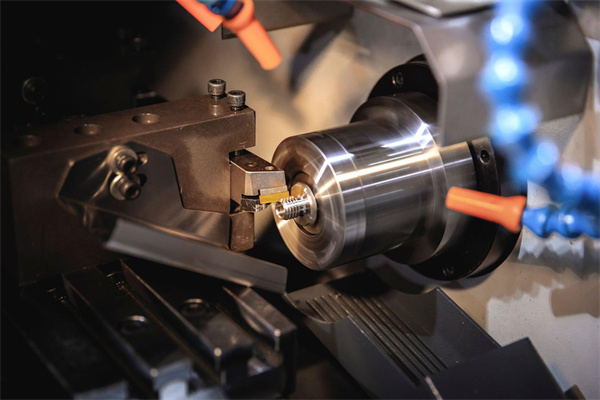

A CNC machine is a computer-controlled cutting and machining tool that can precisely create complex shapes and parts. CNC stands for “Computer Numerical Control,” which means that a computer controls the machine. This machine can perform highly precise operations that would be difficult or impossible to do manually. This article will look at what a CNC machine can be used for and how you could benefit from using one in your business.

CNC Machines in Manufacturing Applications

CNC machines are used extensively in the manufacturing industry as they offer unparalleled accuracy and repeatability when it comes to producing intricate parts. They can also produce parts quickly and cost-effectively compared to manual methods such as drilling or grinding. Many materials can be cut or machined with a CNC machine, including plastics, metals, composites, and more. Common applications for CNC machines include milling, drilling, tapping, turning, engraving, routing, sawing, shearing, chamfering, boring holes, and much more.

Advantages of Using a CNC Machine

Using a CNC machine instead of manual labor offers several advantages over traditional machining or cutting parts. One advantage is that they can produce very precise cuts every time they are used. This means there is less waste material from the process and less time spent on finishing the part due to the high accuracy produced by the machine. Additionally, since the machine operates automatically without requiring human interaction during operation, it reduces operator fatigue. It allows them to focus on other tasks while maintaining high production output levels. Finally, since each part is produced consistently with no variation between pieces, it helps increase overall quality control standards in your facility thus resulting in higher-quality products being delivered to customers.

A CNC machine offers numerous benefits to businesses looking to produce highly accurate parts quickly and cost-effectively. It provides unparalleled accuracy compared to manual labor and can significantly reduce errors associated with traditional machining or cutting materials. Additionally, it helps reduce operator fatigue by allowing them to focus on other tasks while maintaining high output levels without sacrificing quality control standards throughout your facility’s production process. Investing in a good quality CNC machine for your business could potentially make all the difference when it comes to producing high-quality products efficiently and cost-effectively for your customers!

What You Need to Know About Renting CNC Machines

If you’re in the market for a CNC machine, you may have considered renting one. Renting a CNC machine is often more cost-effective than buying one outright, and can provide you with access to the type of machinery that may otherwise be out of your budget. But how do you know which type of CNC machine is best for your project? Let’s take a closer look at the different types of machines available for rent.

Types Of CNC Machines Available For Rent

CNC machining centers come in all shapes and sizes, each designed to perform specific functions. Before deciding which machine is right for your project, it’s important to understand what each type can do. Here are some of the most common types of CNC machines available for rent:

• Lathes – Lathes are used primarily for cutting cylindrical parts from metal or wood. They are also used for boring and drilling holes into materials.

• Mills – Mills are used for cutting complex shapes from metal or wood and drilling and boring holes into materials. They can also be engraved on delicate surfaces like glass or stone.

• Plasma Cutters – Plasma cutters use high-pressure plasma gas to cut through metals that other machines cannot handle, such as stainless steel and aluminum. They can also create intricate designs on metals or other hard materials.

• Welders – Welders join two pieces of metal together by melting them with an electric arc or flame. Different types of welders include stick welders, MIG welders, TIG welders, plasma arc welders, and oxy-acetylene welding equipment.

Renting a CNC machine can provide access to the type of machinery that may otherwise be out of your budget while still allowing you to produce quality products with precision accuracy and repeatability. Whether you need a lathe, mill, welder, or plasma cutter, there is sure to be an option available that meets your needs and budget requirements. With careful research and consideration, finding the perfect machine solution for your next project will be easy!

The Basics of Choosing the Right CNC Machine for Your Needs

The world of CNC machining is constantly evolving and improving, giving businesses greater access to reliable, efficient production capabilities. But with so many choices available, it can be difficult to know which CNC machine is best for your needs. There are a few important factors to consider to ensure you get the right machine. Let’s take a look at the basics.

Consider Your Workload and Production Requirements

The first step in choosing the right CNC machine is considering your workload and production requirements. Think about how much you will use the machine daily, what parts you need to produce, and what materials you will be working with. Knowing this information ahead of time will help you narrow down your options and choose the best type of machine for your needs.

Evaluate Your Budget

The next step is to evaluate your budget for purchasing a CNC machine. This includes the initial cost of buying the machine and any ongoing costs such as maintenance or repairs that may arise over time. It’s important to factor in these costs to choose a machine that fits your budget without sacrificing quality or performance.

Research Manufacturers

Once you know what type of CNC machine you need and what kind of budget you’re working with, it’s time to start researching different manufacturers who offer machines that fit those criteria. Look into their reputation, customer service offerings, warranties, and other factors to help you decide which manufacturer is right for your business needs.

Finding the perfect CNC machine for your needs requires research and thoughtful consideration. Begin by considering your workload and production requirements – this will help narrow down your option

s from the start. Then evaluate your initial budget and any ongoing costs associated with ownership or maintenance; this will help ensure that you get a quality product at an affordable price point. Finally, research various manufacturers who offer products that meet all of these criteria to find one whose reputation fits your company’s values and goals. Following these steps should help guide you toward finding the perfect CNC machining solution for your business needs!

Exploring the Benefits of Renting CNC Machining Equipment

When it comes to buying a CNC machining solution, there are many options available. One option is to buy a CNC machine outright and keep it long-term, while another is to rent one for short-term projects or trials. This article will explore the benefits of renting CNC machining equipment over buying one.

The Cost of Buying a CNC Machine

Buying a CNC machine can be expensive. Depending on the specifications and size of the machine, you could be looking at spending anywhere from several thousand dollars up to hundreds of thousands of dollars. Also, ongoing costs are associated with maintaining and operating a CNC machine such as utilities, labor, materials, etc. So if you’re only going to be using your CNC machine for short-term projects or trials before committing to buying one outright, it might make more financial sense, in the long run, to rent instead.

The Flexibility of Renting a CNC Machine

Renting a CNC machine gives you the flexibility you wouldn’t get when buying one outright. For instance, if you only have a small project that requires occasional use of a specific type of machine tool, then it makes far more sense to rent than buy. You also don’t need to worry about having enough space or resources available since renting allows you to scale up (or down) as needed without any additional investment or overhead cost. Plus when you rent a machine tool rather than buy it outright, you can try out different models before settling on one that best suits your needs without making any long-term commitments or investments upfront.

Safety and Maintenance Considerations

When renting a CNC machining solution from an established rental provider such as Metric Marketing Inc., you can rest assured that all machines are regularly inspected and maintained by experienced professionals according to industry standards and regulations. This means that renting guarantees operators’ safety and protects against costly downtime due to unexpected maintenance issues or malfunctions. Plus when renting from Metric Marketing Inc., our technicians will provide full support during setup and operation so that your team can get back up and running quickly—which is especially beneficial for time-sensitive projects where every minute counts!

Overall renting rather than buying is an excellent way to benefit from all the advantages modern CNC machines offer without getting locked into any long-term commitments or investments upfront. From saving money on initial costs while still having access to top-quality machines and tools with reliable customer service & maintenance support – there really isn’t any downside! If you’re in the market for a high-quality CNC machining solution but don’t want the hassle (or expense) associated with ownership, then consider reaching out to Metric Marketing Inc., today for more information about our rental solutions packages!

Finding a Reputable Rental Company for CNC Machining

If you are in the market to rent CNC machining equipment, it is essential to find a reputable rental company that offers quality customer service. Not all rental companies are created equal and understanding how to locate the right one can save time, money, and hassle down the line. Let’s take a look at the best ways to find a reliable rental company for CNC machining.

Research Reviews and Ratings

When researching potential rental companies for CNC machining, read online reviews and ratings from past customers. This will give you an idea of the company’s reputation in terms of customer service, equipment quality, and overall satisfaction with its products or services. It is important to consult multiple sources to assess how each company has performed in the past accurately.

Inquire About Equipment Quality

When interviewing potential rental companies for CNC machining, be sure to inquire about their equipment quality. Ask questions about their maintenance process and if they use new or reconditioned parts when repairing or replacing any components on their machines. You should also ask if they use certified technicians who have been trained on specific brands or models of CNC machines. Remember that quality often comes at a higher price than lower-quality machines, so make sure you understand what you are getting before signing on with any rental company.

Understand Rental Terms & Conditions

Before renting any CNC machinery from a rental company, ensure you understand all the terms and conditions associated with your agreement. Be clear about when payments are due and how long your agreement lasts before needing renewal or termination—this way there won’t be any surprises down the line! Also, ensure you know who is responsible for maintenance costs during your lease period—you don’t want to be stuck paying extra fees due to unforeseen repair needs!

Renting CNC machinery can be a great way to save money while still accessing top-notch technology. However, finding a reputable rental company that offers excellent customer service and high-quality equipment is essential for this process to go smoothly. By researching reviews and ratings online and inquiring about equipment quality prior to signing up with a particular provider, buyers can ensure that they get exactly what they need at a competitive rate—all without sacrificing satisfaction or reliability! With these tips in mind, finding a reputable rental company for CNC machining should be easy!