[lwptoc]

What is CNC machining, and what are its applications

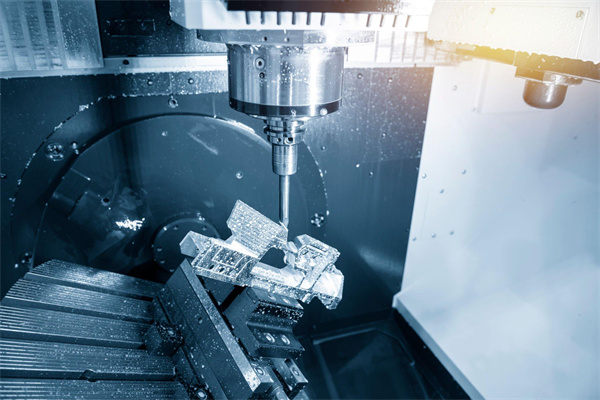

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to create precise parts and components from metal, plastic, and other materials. This type of machining involves the use of specialized cutting tools and programmed instructions to control the movements of the machine. CNC machining is used for various aerospace, automotive, defense, electronics, medical, and industrial equipment applications.

CNC machining is a cost-effective way to produce high-quality parts quickly. The accuracy and repeatability of CNC machining can be very precise compared to manual methods such as drilling or milling. It also offers many advantages over traditional manufacturing processes, including reduced setup times, faster production rates, improved part quality, and consistency. CNC machines can produce high-precision complex shapes at a lower cost than manual methods.

When costing out CNC machining services, it is important to consider several factors such as design complexity, quantity required, material costs, tooling requirements, and lead time needs. On average, you can expect an hourly rate between $50-250, depending on your design’s complexity and desired project speed. Factors such as material costs will also play into this cost estimate as different types of metals have different pricing per kilogram or pound depending on where you are sourcing from. Additionally, tooling requirements may add additional costs, so it’s important to be aware of these when budgeting for your project.

In terms of how much time it takes to complete certain tasks with CNC machining – this depends on several factors, including the size/complexity/material being worked with; still, typically, you can expect anything from 10 minutes up to an hour plus per component, depending on all these variables mentioned above. However, with larger quantities or simpler designs, these production times can drastically reduce due to increased efficiency gained through automation compared to manual labor methods mentioned before (drilling, etc.).

CNC machining has become one of the most widely used processes in modern manufacturing due to its ability to produce complex shapes quickly with high precision at a lower cost than manual methods. This makes it ideal for applications ranging from aerospace components down to medical device implants which require exact tolerances with minimal variation in design between parts produced in batches over large quantities – saving businesses money due to its quick turnaround times combined with its high degree of accuracy & repeatability achieved through programming instructions directly into the machine prior running production cycles.

Overall if you need precision parts that require intricate details, then CNC machining could be an ideal solution for your business needs – although you should always factor in additional costs for toolings and materials when budgeting out any projects using this method ahead of time before committing resources – so that your final product arrives meeting expectation without going over budget!

How does CNC machining work

CNC (Computer Numerical Control) machining is a cutting-edge technology that has revolutionized the way products are manufactured. This advanced process involves using computer-controlled machines to cut, trim, and shape materials into desired shapes and sizes. CNC machining increases precision, efficiency, and accuracy compared to traditional manual machining methods. This blog post will discuss how CNC machining works and how much it can cost per hour.

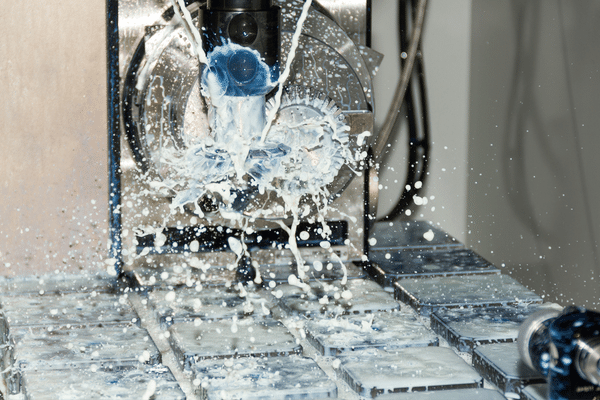

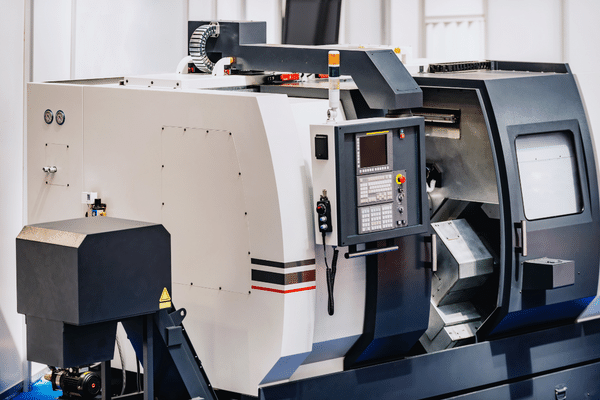

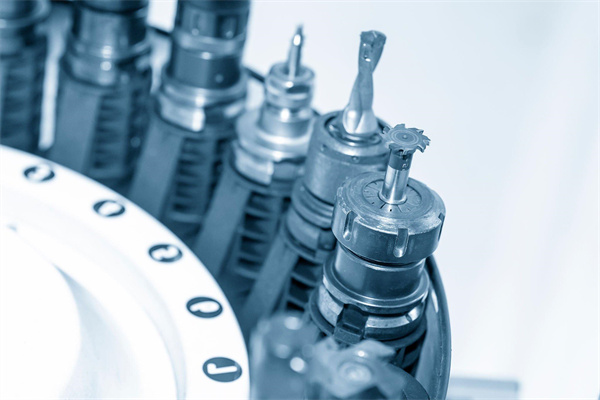

First off, let’s discuss what CNC machinery is. It consists of three main components: the machine tool itself, a controller board that acts as the “system’s ” brain, ” and a CAM (Computer Aided Manufacturing) software program. The machine tool comprises several parts that work together to cut materials with utmost precision. These include an X-Y axis table with an attached spindle head that moves along the surface while cutting material, a Z-axis column that holds the cutting tools, and various other attachments, such as coolant pumps or dust collectors.

The controller board is responsible for driving all motors on the machine tool and accurately controlling each axis movement about the computer’s CAM program instructions. It also contains embedded software programs that control spindle speed, feed rates, depth cuts, and other functions related to machining operations.

Now onto the CAM software program, which provides instructions on how to move along each axis based on a 3D model created in CAD (Computer Aided Design). This virtual model is then translated into G-code, which tells the machine where to move next to cut out complex designs accurately according to specified parameters set by the user. The G-code also contains instructions on when specific cutting tools should be used during different stages of production depending on material type or thickness. The CAM software also takes care of calculating speeds, feeds, depth cuts, and more for them to remain within safe operational limits throughout production time.

So now you know what CNC machinery is, but have you ever wondered how much CNC machining costss per hour? Well, unfortunately, there isn’t any one definitive answer since this depends heavily on factors such as the complexity of your design or the number of axes required for producing it, etc., however; most shops will generally quote their services at around $100-$200/hour as long as they are given accurate information upfront regarding your project’s requirements including material type & thickness, etc. Suppose your project requires additional resources such as cooling systems or special dust containment equipment. In that case, es can vary significantly between shops, so make sure you ask around before committing yourself financially!

To summarize, CNC Machinery uses computer-controlled machines with three main components – machine tools containing motors & axes plus a controller board & CAM software – which are used to create intricate designs from materials with high precision & accuracy. How Much Does Cnc Machining Cost Per Hour? Generally speaking, most shops quote their services at around $100-$200/hour depending heavily on the project’s complexity, but make sure you ask around first if you need additional resources like cooling systems or special dust containment equipment!

The cost of CNC machining per hour

CNC machining is a complex fabrication process that creates precision components and parts for various industries. The cost of CNC machining per hour depends on several factors, including the type of machine used, material costs, finishing requirements, and the project’s complexity. It’s important to understand all these factors and how much your project will cost accurately.

When it comes to CNC machining, one of the most important factors is the machine being used. Most CNC machines are highly specialized units designed to perform specific tasks. Some machines are more expensive than others because they are faster and more efficient or can handle tougher materials. Additionally, newer models often come with features such as automated positioning and cutting systems which can add to their overall cost.

Material costs also play an important role in determining CNC machining costs per hour. Depending on the material being used, additional labor costs may be needed when it comes time to cut or shape the part or component using a CNC machine. Hardness or thickness can also affect material costs and machining times for each part or component being created. Additionally, some metals and plastics require different treatment processes, such as heat treating, which adds an extra layer of complexity when estimating how long a job will take to complete and what it will ultimately cost in terms of materials and labor costs.

Get the complete solution. ↓

The finishing requirements for a given job should also be considered when estimating how much it will cost per hour for CNC machining services. This includes sanding, buffing, or polishing metal parts or components that need good aesthetic presentation or surfaces that require coatings such as paint, powder coatings, or other finishes that require careful application techniques before final assembly.

Finally, the details and complexity of each job should also be considered when looking at the overall cost per hour for CNC machining services. Suppose intricate curves or tight tolerances are involved with the project. In that case,n this could take longer than expected due to having to set up special holding fixtures to ensure accuracy during each cycle run time on the machine itself. Additionally, suppose multiple operations need to be performed on one particular part. In that case, this could lead to extended running times for each job, meaning higher coverall costs for any given project’s completion timescale and, ultimately, its total price tag at the completion stage too!

In conclusion, understanding all aspects associated with any given CNC machining job is key if you want accurate estimates when it comes time to budget accordingly before work commencement! Costs takesry drastically depending on what type of machine is being used along with material types required, but knowing ahead of time what kind of finishing requirements are needed before final assembly takes place is essential too – especially if you want your end product to look professional yet still keeping close tabs on budgets throughout every step along its production journey!

Factors that affect the cost of CNC machining

When it comes to precision manufacturing, CNC machining is often the top choice for many businesses. CNC machining offers many benefits, making it the ideal choice for complex parts and features in various industries. However, the cost is always a factor when considering any precision manufacturing service. So how much does CNC machining cost per hour?

The cost of CNC machining varies depending on the complexity of the part or feature, the material used, and the job size. Generally speaking, CNC machining services can range anywhere from $50 to over $1,000 per hour, depending on these factors.

When considering the cost of CNC machining services, it’s important to understand each factor that affects pricing:

Material: The type of material you use will greatly impact CNC machining. Different materials require different processes and tools to machine them accurately – and some materials are more expensive than others due to availability or difficulty with working with them. Additionally, if you need specialty metals or alloys, this can further increase your costs.

Size: Larger parts require larger tools which will add to overall labor costs associated with CNC machining services. It’s also important to consider not just the size of your part but also its shape – since more complicated shapes may take longer to program into the tooling system.

Complexity: Complex parts may require multiple steps during programming and milling, which adding and cost associated with the overall production time for your part or feature. If your part requires different finishing processes, such as sandblasting or polishing, that will also add cost.

Timeframe: A shorter turnaround time usually equates to higher costs simply because fewer people are available to manage a rush job compared to one with more lead time ahead of it.

In addition to these primary factors that determine the price of CNC machining services, other secondary aspects can affect pricing too, such as overhead expenses incurred by shops due to staff wages, taxes, and insurance; rent or lease prices for space; utilities; depreciation on equipment; etc……… All these variable costs must be accounted for when determining to price for each job. So it’s best practice (and good business sense) for shops to charge according to a “book rate” established by industry standards which takes all these factors into account before quoting customers special prices per job/hourly rates, etc………

Knowing how much CNC machining typically costs per hour can help you better plan your budget when utilizing precision manufacturing services – but keep in mind that actual rates may fluctuate based on several factors mentioned above!

How to reduce the cost of CNC machining

Many factors come into play when it comes to the cost of CNC machining. From materials to labor costs and more, businesses need to know how much they can expect to pay when outsourcing their CNC machining services. The good news is there are several ways to reduce the cost of CNC machining without sacrificing quality. If you’re looking for ways to lower your overall cost of CNC machining, read on for tips on how to do just that.

One of the most effective ways to reduce the cost of CNC machining is by streamlining your production process. By optOptimizingworkflow and identifying areas where you can make improvements, you significantly reduce costs associated with production time and labor fees. For example, if you’re using multiple machines in your production line, consider consolidating those machines into one machine or a single station that can perform all tasks at once instead of having multiple machines operating separately. This optimization will not only cut down on total production time but also help you save money on labor costs.

Another way to lower CNC machining costs is by carefully choosing materials when designing parts. Choosing materials based on their strength-to-weight ratio and considering other properties, such as thermal conductivity or wear resistance, will allow you to select materials more suitable for producing higher-quality parts at a lower cost than other alternatives. In addition, selecting material grades designed specifically for CNC machining can result in faster cutting speeds while providing better surface finish results with fewer passes through the machine. This helps minimize cycle times and ultimately reduces overall costs associated with manufacturing components using CNC machining services.

Additionally, utilizing modern technologies such as CAD/CAM software and simulation tools can help maximize efficiency when designing parts for manufacturing using CNC machining services. These tools enable designers to quickly develop models that consider all aspects of the part design, such as material selection, tooling requirements, and expected machine performance parameters, before starting the manufacturing process. This enables designers to optimize their designs for maximum throughput rather than simply following traditional design rules, which often lead to slower manufacturing cycles, resulting in higher overall costs per part produced via CNC machining services.

Finally, alternative vendors may also be beneficial when reducing CNC machining costs. Vendors offer rates depending on the batch size or complexity of manufactured parts. Research each vendor thoroughly before deciding who best fits your needs in terms of pricing structure and ability to meet deadlines, among other factors. When shopping around for CNC machining services, it is important not only to focus on price but also to consider turnaround times as well as any additional services offered, such as post-processing operations or assembly work, when making an informed decision regarding which vendor best meets your specific requirements in terms of quality products delivered at a competitive rate per hour basis.

In conclusion, several strategies are available for reducing the cost associated with CNC machined components without sacrificing quality or accuracy in results obtained from machines used during production. Streamlining production processes through consolidation whenever possible, careful selection of materials, taking advantage of mof modern software tools, fand finding alternative vendors are all approval should be considered when attempting to reduce reduces machining costs while still maintaining the highest level oof output during these operations