introduction

Introduction

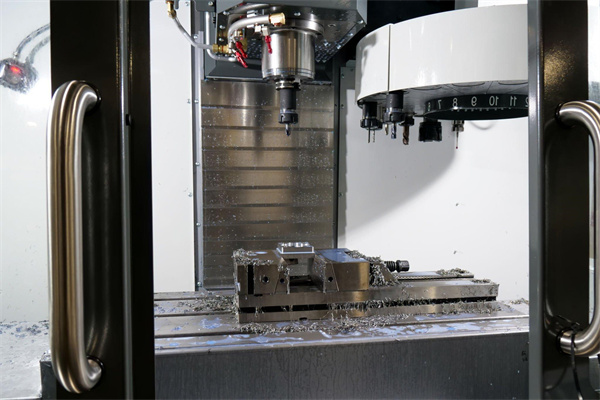

CNC machining is a manufacturing process that uses computer-controlled tools to shape and form parts from various materials. It is a process that has revolutionized the way that engineers and designers create parts and products. This process has become increasingly popular due to its accuracy, repeatability, and ability to produce complex geometries quickly.

Definition of CNC Machining

CNC machining is a subtractive manufacturing process that utilizes tools such as mills, lathes, routers, and grinders to cut parts from a solid block of material. It is a precise process that allows for creating of complex geometries and shapes with tight tolerances. CNC machining is often used to produce parts for various industries, such as aerospace, automotive, medical, and electronics.

Benefits of CNC Machining

CNC machining has many benefits, making it an attractive option for engineers and designers. Precision CNC machining can achieve extremely tight tolerances, which can be critical for certain products. It also offers the ability to produce parts with complex geometries and shapes quickly and accurately. In addition, CNC machining is a more cost-effective and efficient method of production than traditional machining processes, as it requires less manual labor and has higher throughput.

Materials Used in CNC Machining

CNC machining can produce parts from various materials, including metals such as aluminum, steel, and titanium, as well as plastics, composites, and ceramics. Each material has advantages and disadvantages, so it is important to consider the application and select the best material for the job.

Conclusion

CNC machining is essential for producing parts and products requiring precise tolerances and complex geometries. It is a fast and cost-effective method of production that offers high accuracy and repeatability. With its wide range of capabilities and materials, CNC machining is an invaluable tool for engineers and designers.

overview

Introduction to CNC Machining

CNC machining is a technology that has been around for decades, providing manufacturers with the ability to automate the entire manufacturing process. CNC machining involves using computer numerical control (CNC) machines, which are computer-controlled tools programmed to perform various machining operations. This technology has revolutionized the manufacturing industry, making it possible to quickly and efficiently produce complex parts with high accuracy and repeatability. In this blog post, we will take a look at the history of CNC machining, the benefits it provides, and some of the types of machining operations it can be used for.

History of CNC Machining

The history of CNC machining dates back to the 1950s when John T. Parsons first developed it. John T. Parsons was an engineer at the Massachusetts Institute of Technology (MIT) who developed a system for controlling a machine tool using a computer. The “MIT CNC,” was the first CNC machining system to be developed.

Since then, CNC machining has evolved greatly, with more sophisticated machines and complex machining operations being developed. Today, CNC machining is used in various industries, from aerospace to automotive and even medical applications.

Benefits of CNC Machining

CNC machining provides several benefits over traditional machining operations. The most significant benefit is the ability to produce parts with greater accuracy and repeatability than manual machining. CNC machines are programmed with exact instructions, so each part is machined to the exact specifications. This eliminates the need to manually adjust tools or other machining parameters to achieve the desired result.

Additionally, CNC machining is more efficient than manual machining. CNC machines can produce parts at a much faster rate, which can significantly reduce production time and costs. CNC machines also require less operator intervention and can be programmed to operate even when no one is present, making them ideal for automated production.

Types of Machining Operations

CNC machining can be used for various machining operations, including milling, turning, drilling, and even laser cutting.

Milling is the process of cutting material from a part to create a specific shape or form. This process is often used to create complex shapes and features that would be difficult to produce with manual machining.

Turning is the process of spinning a part to shape it. This process is often used to create cylindrical parts or features.

Drilling creates a hole in a part to create a specific shape or form. This process is often used to create precise holes for fasteners.

Laser cutting uses a laser beam to cut away material to create a specific shape or form. This process is often used for intricate or detailed parts that would be difficult to produce with manual machining.

Conclusion

CNC machining is an advanced technology that has revolutionized the manufacturing industry. It allows manufacturers to quickly and efficiently produce complex parts with high accuracy and repeatability. It is also more efficient than manual machining, requiring less operator intervention, and is capable of operating without supervision. CNC machining can be used for various machining operations, including milling, turning, drilling, and laser cutting.

types of CNC machines

When it comes to CNC machines, there are three main types: lathe machines, milling machines, and drilling machines. They are used for various applications in the manufacturing industry, from shaping and cutting to drilling and milling. Understanding the differences between these three types of machines can help you decide which is best for your business.

Lathe machines shape materials into a specific size, shape, and configuration. They can also be used for threading, knurling, and boring. Lathes are available in manual and CNC models and come in various sizes. They are commonly used to produce cylindrical parts, such as screws, bolts, and studs.

Milling machines are used to create parts with complex profiles and shapes. They can cut slots, drill holes, and create intricate shapes. Milling machines come in various sizes and are available in manual and CNC models. They are used to produce intricate parts, such as gears, cams, and dies.

Drilling machines are used to create holes in materials. They can be used to drill holes for bolts and screws and create counter-bores and counter-sinks. Drilling machines are available in manual and CNC models and come in various sizes.

All three types of CNC machines offer a range of benefits. They are precise, consistent, and reliable and offer a wide range of capabilities. CNC machines are also easier to use than manual machines and require less setup time.

Before selecting a CNC machine for your business, it is important to consider the types of materials you will be working with and the types of jobs you will be performing. Each type of CNC machine has advantages and disadvantages regarding speed, accuracy, and cost.

Lathe machines are best for producing cylindrical parts, such as screws and bolts. They can also be used for threading and knurling. Milling machines are best for producing complex shapes and profiles, such as cams and die. Drilling machines are best for creating holes in materials.

When selecting a CNC machine for your business, it is important to research and determine which type of machine best suits your needs. Understanding the differences between the three CNC machines can help you make an informed decision.

production processes

Production processes are essential for the manufacturing of products. The various processes include computer-aided design (CAD), computer-aided manufacturing (CAM), material selection, and machining. This article will explain each process and how they are used to create the desired product.

Computer-Aided Design (CAD)

Computer-aided design (CAD) is a process that uses computers to create detailed designs for a product. This helps the manufacturer accurately create the product to the customer’s specifications. CAD is used to create designs that are then used to create the product. CAD is used in product design, engineering, and manufacturing.

Computer Aided Manufacturing (CAM)

Computer-aided manufacturing (CAM) is a process that uses computers to control the manufacturing process. This helps the manufacturer create the product cost-effectively and efficiently. CAM also helps to reduce errors and mistakes during the manufacturing process.

Material Selection

Material selection is an essential part of the manufacturing process. The manufacturer must select the right material for the product to ensure that it meets the customer’s specifications and is of the highest quality. This involves researching different materials and selecting the best one for the application.

Machining Processes

Once the materials have been selected, the manufacturer must use machining processes to create the desired product. This involves cutting, forming, and drilling the parts to the correct shape and size. Common machining processes include CNC machining, 3D printing, and injection molding.

CNC machining is a machining process that uses computers to control the cutting and shaping of materials. A CNC machine uses a computer code to control the cutting tools and the movement of the materials. CNC is a precise and accurate machining method widely used in manufacturing.

Conclusion

Production processes are essential for the manufacturing of products. Each process, such as computer-aided design (CAD), computer-aided manufacturing (CAM), material selection, and machining processes, are all important steps in the production process. Using the right processes, the manufacturer can create the desired product that meets the customer’s specifications and is of the highest quality.

applications

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to cut and shape materials into the desired form. As the name suggests, CNC machining is a computer-controlled process used in various industries, such as automotive, aerospace, medical, and consumer goods manufacturing. It is a highly precise and automated process to create precise components and intricate designs.

In CNC machining, a cutting tool is attached to a machine and programmed to move precisely along the machined material. The cutter can be programmed to move along a pre-determined path, follow a design, or cut through the material with a certain degree of accuracy. The machines used in CNC machining are typically computer-controlled and can be programmed to perform multiple tasks simultaneously.

Get the complete solution ↓

The automotive industry is one of the most popular industries that utilize CNC machining. Automotive parts are typically created in high volumes and require high precision and accuracy. The CNC machining process cuts and shapes various parts, such as engine blocks, transmission housings, and wheel hubs. CNC machining is also used to create complex technical shapes, like gear teeth and camshafts.

The aerospace industry also heavily relies on CNC machining to create intricate and precise components for aircraft and spacecraft. The CNC machining process creates propulsion systems, landing gear, and instrumentation. It also creates complex shapes, such as turbine blades and fuselage frames.

The medical industry also utilizes CNC machining to create components and devices used in medical devices and treatments. CNC machining is used to create surgical instruments, implants, and prosthetics. The precision and accuracy of the process allow for the creation of intricate components tailored to the patient’s specific needs.

Finally, CNC machining is also used in consumer goods to create products such as jewelry, toys, and furniture. It is used to create intricate shapes and designs that would otherwise be impossible to create with traditional manufacturing techniques. The process is also used to create products with high precision and accuracy.

In conclusion, CNC machining is a highly precise and automated manufacturing process used in various industries, such as automotive, aerospace, medical, and consumer goods. It creates intricate components, parts, and devices for various applications. The process is used to create products with high accuracy and precision, allowing for the creation of complex shapes and designs.

conclusion

CNC machining is a cutting-edge technology used in a variety of industries. It is a manufacturing process involving using Computer Numerical Control (CNC) machines to shape and mold materials. The process is highly automated and can create extremely precise parts and products.

At its core, CNC machining is a subtractive manufacturing process that involves cutting or drilling away material to create a desired shape. It’s used to create complex shapes and tight tolerances that can’t be achieved with traditional manufacturing processes. CNC machining produces everything from intricate medical device components to automotive and aerospace components.

This guide will provide a comprehensive overview of CNC machining. We’ll look at the history of CNC machining, the different types of CNC machines, the benefits of CNC machining, and the different materials that can be machined with CNC machines. We’ll also look at the various industries that use CNC machining and the various processes and techniques used to produce parts and products with CNC machines.

History of CNC Machining

CNC machining has been around since the 1950s when it was first used to program a numerical control (NC) machine. This enabled the machine to make repeatable, precise cuts with a single setup. Over the years, CNC machines have become more advanced and feature computer-controlled motors, spindles, and tooling.

Types of CNC Machines

CNC machines come in a variety of shapes, sizes, and configurations. The three-axis machine is the most common type of CNC machine, which is used for most CNC machining applications. Other types of CNC machines include four-axis machines, five-axis machines, and multi-axis machines.

Benefits of CNC Machining

CNC machining provides several benefits for manufacturers. It’s highly accurate and repeatable, so parts and products can be produced with tight tolerances. CNC machining also reduces the need for manual labor, which increases productivity and reduces costs. CNC machines can also be programmed to produce parts and products with very complex geometries.

Materials Used for CNC Machining

CNC machining can be used to machine a variety of materials, including metals, plastics, composites, and more. The most common materials for CNC machining are aluminum, steel, brass, bronze, and titanium.

Industries That Use CNC Machining

CNC machining is used in various industries, including aerospace, automotive, medical, and more. CNC machining is also used to produce components for consumer electronics, such as smartphones, tablets, and laptops.

Processes and Techniques Used in CNC Machining

CNC machining involves various processes and techniques, including milling, drilling, turning, tapping, and grinding. Depending on the application, different cutting tools, such as end mills and drills, are used to create the desired shape.

Conclusion

CNC machining is an advanced manufacturing process that uses Computer Numerical Control (CNC) machines to shape and mold materials. It’s used to create complex shapes and tight tolerances that can’t be achieved with traditional manufacturing processes. CNC machining is used in various industries to produce everything from medical device components to automotive parts to aerospace components. CNC machining provides several benefits for manufacturers, including increased accuracy, repeatability, and reduced costs. It can machine various materials, including metals, plastics, and composites. CNC machining is a cutting-edge technology that produces high-precision parts and products with complex geometries.