What is a CNC machine?

CNC machines, or Computer Numerical Control machines, are automated machines used in industrial and manufacturing processes to perform various tasks. They are used in aerospace, automotive, agriculture, and many others. CNC machines create parts and components that would otherwise be too complex to produce by hand.

CNC is Computer Numerical Control and refers to a computer used to control a machine’s movements. This computer is programmed with instructions to move the machine in a certain way, allowing it to produce parts and components with high accuracy and precision. CNC machines are used in many applications and can produce anything from simple products to complex medical devices.

Get the complete solution ↓

CNC machines are generally divided into two categories: milling machines and lathes. Milling machines are used to produce parts with a revolving cutting tool, while lathes are used to produce parts with a rotating cutting tool. These CNC machines are used for various tasks, such as cutting, drilling, grinding, polishing, and more.

When it comes to the operation of a CNC machine, the operator will typically work with a computer-aided design program (CAD). This program will allow the operator to enter instructions for the machine. Once the instructions are entered, the machine will then follow those instructions and create the part or component as specified.

The main benefit of using a CNC machine is that it can produce components with high accuracy and precision. This is why CNC machines are used in various industries, from medical devices to aerospace engineering. Additionally, CNC machines require less human intervention than manual tools, meaning they are more cost-effective and efficient.

Overall, CNC machines are a great tool for businesses looking to produce parts and components quickly and accurately. With the right programming and setup, businesses can create high-quality parts and components with minimal effort. CNC machines are invaluable for businesses that need to produce parts and components with high accuracy and precision.

history of CNC machining

CNC machining is a manufacturing process that uses computer-controlled tools to shape materials. It has been around since the late 1950s, and its use has become increasingly important in modern manufacturing.

CNC machining is a manufacturing process that uses computer-controlled tools to shape materials. It has been around since the late 1950s, and its use has become increasingly important in modern manufacturing. CNC machining has become commonplace in many industries, from medical devices to automotive parts, and its importance is expected to grow.

The history of CNC machining can be traced back to the 1950s with the invention of the numerical control (NC) machine. John T. Parsons, an American engineer, developed this machine. The NC machine was the first to use a computer to control the cutting tool.

In the 1960s, the NC machine was further refined to create the first computer numerical control (CNC) machine. This machine was developed by John Parsons and a team of engineers at the Massachusetts Institute of Technology (MIT). The CNC machine used computer programs to control the cutting tool, which made it more sophisticated than its predecessor.

Since then, CNC machining has continued to evolve. In the 1970s, the process was enhanced with the invention of the 3-axis CNC machine. This machine produced more accurate and intricate shapes than the 2-axis machine.

In the 1980s, CNC machining was further improved with the invention of the 4-axis and 5-axis machines. These machines allowed for more complex shapes to be created.

In the 1990s, CNC machining was further refined with the invention of the CNC milling machine. This machine could create more accurate shapes than those created by the 4-axis and 5-axis machines.

CNC machining has come a long way since its invention in the 1950s. It has become an essential tool in many industries, and its importance is expected to grow. It is now used to create various products, from medical devices to automotive parts.

As technology advances, CNC machining will continue to evolve and become even more essential in the manufacturing industry. CNC machining is here to stay, and its importance is expected to grow.

CNC machine components

Are you interested in learning about CNC machine components? If so, you’ve come to the right place! In this blog, we’ll explore the components of a CNC machine, including their uses and importance to manufacturing. We’ll also discuss the differences between manual and CNC machines and how they operate. CNC stands for “Computer Numerical Control” and is an automated manufacturing process that uses computers and numerical data to control machines. It is used to create consistent and accurate parts quickly and efficiently. CNC machines are commonly used in various automotive, aerospace, and medical industries.

CNC machines are composed of several components that help them perform their functions. These components are the following:

1. Tooling: This is the most important component of a CNC machine. It includes the tools that are used to shape and cut the material. The tools range from cutting tools, such as drills and end mills, to shaping tools, such as lathes and mills.

2. Computer Controls: This is the part of the machine that allows it to be programmed and operated. It includes the computer (or controller) that gives the machine its instructions and the software, hardware, and interface that allow the machine to be operated and monitored remotely.

3. Drive Motors: The drive motors are responsible for powering the tools and controlling the cutting speed. Depending on the application, the motors typically use either stepper motors or servo motors.

4. Axis: The axes are the machine parts that move the tools and material. They can be either linear or rotary, depending on the application.

5. Workholding: Workholding is the part of the machine that holds the material in place while the tools are operating. It typically includes clamps, fixtures, and other devices that hold the material in the desired position.

6. Coolant Systems: Coolant systems keep the tools and materials cool while being worked on. This prevents the tools from overheating and ensures a longer tool life.

CNC machines are an essential part of modern manufacturing and have revolutionized production. They are often used in place of manual machines because they are faster, more accurate, and more consistent. They are also used to produce parts that are too complex or precise for manual machines.

While manual machines are still used in certain applications, they are increasingly being replaced by CNC machines in many industries. This is due to CNC machines’ advantages over manual machines, such as increased accuracy, faster production, and decreased labor costs.

Overall, CNC machines are an integral part of modern manufacturing. By understanding the components of a CNC machine, you can better understand how it works and why it is so important for modern production.

types of CNC machines

CNC machining has changed the modern manufacturing industry in countless ways. A CNC machine is a computer-controlled tool used to manufacture complex parts and components with exceptional precision. CNC machining can create various components, including metal, plastic, and composite parts.

There are four main types of CNC machines: milling, turning, laser cutting, and EDM (electrical discharge machining). Each type of CNC machine is built to work with different materials and is suited for different tasks. This article will cover the four types of CNC machines and provide a brief overview of their capabilities.

Milling Machines

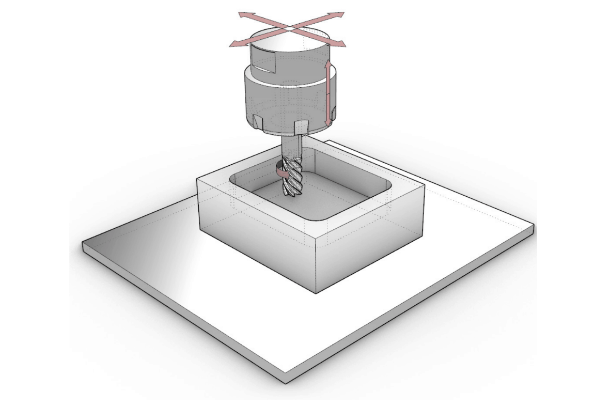

Milling machines are used for a variety of metal machining tasks. They can cut intricate shapes in metal, wood, and other materials. Milling machines use rotary cutting tools such as end mills, drills, and routers to remove material from a workpiece.

Milling machines are extremely versatile and can be used for various applications, from drilling holes and shaping edges to creating complex 3D shapes and surfaces. Milling machines are often used in automotive, aerospace, and electronics manufacturing.

Turning Machines

Turning machines create parts by rotating a workpiece and feeding a cutting tool into the rotating material. Turning machines are ideal for machining cylindrical parts such as shafts, spindles, and bushings.

Turning machines can use single-point or multi-point cutting tools. Single-point cutting tools are used to create simple shapes and details, while multi-point cutting tools are used to create more complex shapes. Turning machines are often used in the automotive, aerospace, and medical device industries.

Laser Cutting Machines

Laser-cutting machines use a high-powered laser beam to cut or engrave material. Laser-cutting machines can cut wood, plastic, metal, and glass with incredible precision. Laser-cutting machines are often used in the automotive and electronics industries.

EDM Machines

Electrical discharge machining (EDM) machines use an electrical current to erode a workpiece, creating intricate shapes and details. EDM machines can machine extremely hard materials such as hardened steel and other alloys. EDM machines are often used in the aerospace and medical device industries.

Conclusion

CNC machines are incredibly versatile tools, and there are a variety of types to suit different needs. Milling machines are ideal for machining complex shapes in metal, wood, and other materials; turning machines are great for machining cylindrical parts; laser cutting machines can create intricate designs in various materials; and EDM machines are perfect for hard machining materials. No matter what type of CNC machine you need, there’s sure to be one perfect for the job.

What can CNC machines be used for?

CNC Machines are found in all corners of the industry, from small, family-run operations to large, multi-national corporations. CNC stands for computer numerical control; as the name suggests, these machines are controlled by a computer. They are used to create precise parts and components with high accuracy and repeatability.

CNC machines have been around for decades and have been used in all industries, from automotive to aerospace. Their versatile nature means they can be used to create a variety of parts and components, ranging from simple parts like screws and nuts to complex components like aerospace components and medical devices.

So, what can CNC machines be used for? The answer is virtually anything you can think of! Here are some of the most common uses for CNC machines:

1. Cutting: CNC machines can be used for various cutting applications, from cutting metal to wood and plastic. The precision of the cuts makes them ideal for applications where accuracy is key.

2. Machining: CNC machines create parts from raw materials. This process uses various tools to create parts from metal, plastic, wood, and other materials.

3. Drilling: CNC machines are used to drill various material holes. They can be used for drilling small holes in metal or larger holes in wood and plastic.

4. Milling: CNC machines are also used for milling operations, which involve removing material from a workpiece to create a desired shape. This process involves the use of a variety of cutting tools to shape the material.

5. 3D Printing: CNC machines can also be used for 3D printing, which involves creating three-dimensional objects from a computer-aided design (CAD) file. The CNC machine moves a print head to create the desired object layer-by-layer.

The uses for CNC machines are virtually limitless. They can create various parts and components, ranging from simple items to complex, precision parts. CNC machines are found in all corners of the industry and are essential for ensuring accuracy and repeatability in the manufacturing process.

benefits of using a CNC machine

As the manufacturing industry continues to evolve, CNC (Computer Numerical Control) machines have become an integral part of the process. CNC machines are highly efficient, reliable, and accurate tools that benefit various industries. This blog will discuss numerous advantages of CNC machines for your machining operations.

1. Precision and Accuracy

CNC machines are designed to create extremely precise and accurate parts. These machines use a computer-controlled system that follows instructions given by a programmer to create parts with high precision. This helps ensure that each part is consistent and meets the desired specifications.

2. Efficiency

CNC machines are much faster than manual machines, allowing you to complete more parts in less time. These machines can also run continuously, while manual machines can only run when an operator is present. This helps reduce labor costs and increases efficiency.

3. Cost-effectiveness

CNC machines are much more cost-effective than manual machines. They require less manual labor, and because they are faster, they can complete more parts in a shorter amount of time. This helps reduce costs and increases profits.

4. Versatility

CNC machines are extremely versatile and can create a wide variety of parts. They can be programmed to create complex shapes and sizes for milling, drilling, and cutting. This makes them ideal for creating a variety of parts for different industries.

5. Quality

CNC machines are designed to create parts with high quality and consistency. This helps ensure that each part is as close to perfect as possible. The machines are also designed to reduce the possibility of human errors, which helps ensure that each part is of the highest quality.

6. Safety

CNC machines are much safer than manual machines, as they are designed to reduce the possibility of human error. They also reduce the risk of injury, as they are designed to eliminate the need for manual labor. This makes them ideal for any manufacturing operation.

Overall, CNC machines offer a wide range of benefits for various industries. They are extremely precise, efficient, cost-effective, versatile, and safe, making them an ideal choice for any manufacturing operation looking to save time and money. If you’re considering using CNC machines for your machining operations, be sure to take the time to research the different models and determine which machine is best suited for your needs.