[lwptoc]

What is a CNC machine

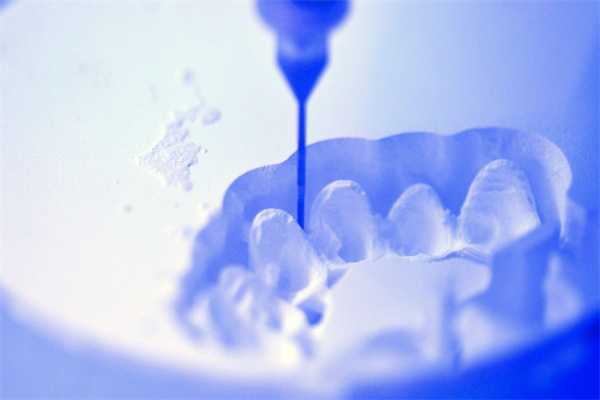

CNC machines have become increasingly important in modern manufacturing processes. They are used to precisely cut and shape materials with high accuracy, consistency, and repeatability levels. CNC stands for Computer Numerical Control and refers to the automation of tools through computer programming. CNC machines can be used for various applications in different industries, from product prototyping to automotive production. But what exactly is a CNC machine?

A CNC machine is a tool that uses computers to control automated cutting or machining operations. The tool consists of a fixed or moving platform called a worktable which holds the material that needs to be machined or cut. It is connected to one or more computer numerical control (CNC) units which generate the necessary machine code commands based on the input program. The commands are sent directly to the tool as it rotates around its center axis, cutting and shaping the material according to pre-programmed instructions.

CNC machines come in all shapes and sizes, depending on their intended use. Some are large industrial machines capable of cutting and shaping large parts. In contrast, others are small desktop devices designed for smaller prototype projects or hobbyist artisans creating sculptures and decorative items at home. While there are many different types of CNC machines, they all have one thing in common: they all have multiple axes of motion, which allow them to move in three directions – x, y, and z – simultaneously.

The number of axes that a CNC machine has depends on its type, but most range from 3-6 axes, with some having up to 12 axes for complex industrial applications such as milling turbine blades or creating intricate carvings in stone or wood. Each axis represents an additional degree of freedom that allows the machine greater flexibility regarding how it moves around an object – this is why some models can create complex 3D shapes. In contrast, others may only be able to cut straight lines along two axes.

So how many axes can a CNC machine have? The answer depends entirely on its type and intended use – however, most models range from 3-6 axes, with some having up to 12 for very specialized industrial applications such as milling turbine blades or intricate carvings in stone or wood. Additionally, newer multi-axis systems offer even more versatility by allowing users to combine linear interpolation with circular interpolation, making them ideal for complex surface machinings tasks like thread milling and form turning.”

How many axes can a CNC machine have

When it comes to CNC machines, one of the most commonly asked questions is, “how many axes can a CNC machine have?” This question is not easy to answer as there are many different types of CNC machines, each with unique capabilities. In this blog post, we will delve into the various types of CNC machines and explore their capabilities regarding the number of axes they can support.

Let’s discuss the two main types of CNC machines: milling machines and lathes. Millers are typically used for machining operations such as cutting, drilling, reaming, counterboring, shaping, and planning. Lathes are used for turning operations such as threading, grooving, and facing. Both these types of machines usually have three axes: X-axis (left to right), Y-axis (front to back), and Z-axis (up and down). However, some advanced models may have more than three axes depending on what kind of machining operations they are designed for.

Another type of CNC machine is the multi-axis CNC router. Such machines have multiple axes allowing them to tackle complex jobs precisely. Multi-axis routers usually come with four or five axes, but some may even have more than five axes, depending on their design. The number of axes also depends upon the particular job requirements and the speed at which a router needs to operate to produce high-quality parts quickly and efficiently.

Finally, there are 3D printers that use two or more additional axes compared to traditional milling and turning machines. These additional axes enable 3D printers to create complex three-dimensional shapes from designs created by CAD software packages. 3D printers typically have five or more axes, although certain advanced models may feature up to nine or even twelve separate working areas controlled by individual motors.

In conclusion, it is difficult to answer the question “how many axes can a CNC machine have?” since many factors are involved, such as the type of machine, job requirements, speed considerations, etc. However, it is safe to assume that most CNC machines come with three main linear axes. At the same time, multi-axis routers and 3D printers offer more options regarding the number of supported working areas under the control of individual motors.

What are the benefits of having multiple axes on a CNC machine?

Creating intricate and complex parts from a wide variety of materials is one of the biggest advantages of owning a CNC machine. CNC stands for Computer Numerical Control, a machine that can execute commands from computer programs and use tools to cut, shape, or drill materials as required. Depending on the type of CNC machine you own, it may be able to work with multiple axes – but what are the benefits? In this blog post, we’ll discuss how many axes a CNC machine can have and the advantages of having multi-axis capabilities.

First, let’s address how many axes a CNC machine can have. Generally speaking, most machines are three-axis machines, meaning they can move in three directions: X (lengthwise), Y (widthwise), and Z (up/down). This allows for basic cutting operations like drilling, milling, and turning. However, some machines feature extra axes – such as A (rotate) or B (tilt) – which gives them more flexibility during operation.

The main benefit of having multiple axes on your CNC machine is that it allows you to create complex parts easily. With additional axes, you can move around materials more easily, making detailed shapes or cuts that wouldn’t be possible with just three axes alone. For example, if you wanted to create a part with an angled surface or an intricate curve, then having an additional axis would allow you to accurately complete this task without any additional setup time or tooling changes. Additionally, having multiple axes can also help speed up production times by reducing set-up time and improving accuracy when machining multiple parts simultaneously due to its ability to repeat motions accurately across different dimensions.

Another advantage is that multi-axis machines are much more versatile than traditional 3-axis models when working with certain materials. This is especially true for composite materials such as plastics which often require special tools to achieve the desired finish or texture. Adding extra axes allows you to maneuver around such materials in ways that wouldn’t be possible otherwise. Furthermore, suppose you need to switch between different tasks within a single job. In that case, multi-axe machines make this much easier, too, since they can quickly adjust their positions according to varying requirements instead of wasting time changing tools each time something different needs to be done (e.g., drilling then milling).

Finally, something else worth noting is that most multi-axis CNC machines have built-in safety features which help reduce risk factors associated with using them – another great benefit! As these machines become more sophisticated, they’re equipped with sensors and other devices that monitor their movements and alert operators when anomalies arise so they can take appropriate action before any damage occurs.

Get the complete solution ↓

In conclusion, numerous benefits are associated with having multiple axes on your CNC machine, from increased efficiency and versatility when creating complex parts to improved safety features; there’s no denying these extra capabilities’ advantages! Whether you’re looking for better control over material manipulation or want faster production times to boost your bottom line, investing in one of these powerful multi-axes pieces of machinery could be exactly what you need!

How do you determine the number of axes needed for your project?

When it comes to CNC machines, there are many questions about how many axes can a CNC machine have. The answer depends on the type of machine being used and the project that needs to be done. Generally, a CNC machine can have anywhere from 3 to 5 axes, with some capable of handling up to 6 or 7. The number of axes needed is determined by the project’s complexity and the required features.

For example, 3-axis machines are generally used for simpler projects such as drilling and cutting. This setup uses the X-Y plane for movement while the Z-axis handles depth control. This type of system can produce parts with flat surfaces. Still, it is limited in its ability to produce complex shapes due to its limited number of rotational movements. Additional axes may be necessary for more complex projects requiring multiple types of movement and rotation.

4-axis systems add a rotational axis (A) to the X-Y-Z setup for improved flexibility when creating parts with three-dimensional shapes or form contours. These machines can also perform both milling and turning operations in one operation. Additionally, some 4-axis systems come with a fourth rotary axis at the tooling station, allowing for even more motion and flexibility when producing parts with curved surfaces or angled cuts.

Recommend reading:

5-axis machines use all five axes—X, Y, Z plus two additional rotary axes—to create complex parts with precise angles and finishes in fewer operations than traditional 4-axis systems can provide. The ability to tilt and rotate the workpiece during machining offers greater accuracy when intricate machining geometries such as molds or dies where maintaining precise angles is critical for success.

Finally, 6 & 7-axis machines have been developed recently for even greater flexibility when machining complex shapes in one operation without having to reposition or reset the part multiple times between operations. With six or seven axles available, these systems offer manufacturers unprecedented access to formerly impossible applications, such as manufacturing turbine blades from solid metal blocks using just one piece of equipment!

In conclusion, when determining how many axes your specific CNC project needs, it’s important to consider what type of material you’re working with and what kind of results you’re targeting before making your decision. For simple tasks like drilling and cutting, a 3-axis machine may do just fine, while more complicated jobs may require 4-, 5-, 6-, or even 7-axis models depending on what needs to be done! Knowing what you need ahead of time will help ensure that whatever type of CNC machine you choose will get your job done right!

What are some common applications for multiple axes on a CNC machine

Multiple axes on a CNC machine can be a great tool for many applications. Multi-axis machines produce components with complex shapes, such as curved and twisted parts, that would be difficult or even impossible to produce with traditional machining methods.

The most common type of multi-axis CNC machine is the 3-axis machine. These machines have three linear axes: X, Y, and Z. The X and Y axes are horizontal (or flat) movements, while the Z axis is vertical. With a 3-axis machine, you can cut 2D profiles such as pockets and contours in flat material.

However, there are CNC machines that offer more than three axes of movement—sometimes referred to as “multi-axis” or “5-axis” machines—which allow for more intricate cuts that would otherwise not be achievable on traditional 3-axis machines. A 5-axis machine consists of three linear axes (X, Y, and Z) plus two rotational axes (A and B). The extra two rotational axes provide access to more complex cutting angles than possible on a 3-axis model. This allows for more intricate pieces to be created with fewer setups since the material does not need to be repositioned each time the cut angle changes.

Multi-axis CNC machines are essential for industries like aerospace, where complex component shapes are commonplace. These machines can create turbine blades, airfoils, and other intricate parts needed in this industry. Other industries like automotive also use multi-axis CNC machines due to the complexity of some component shapes required in vehicle production. Similarly, these CNC machines can also help speed up processes in medical device manufacturing, where intricate components are often much quicker to produce using a multi-axis CNC machine than traditional machining methods.

Regarding capabilities, 5-axis machines typically offer better flexibility than 3-axis ones when producing complex parts with tight tolerances at high speeds. They can take full advantage of powerful CAD/CAM software that optimizes tool paths based on part geometry, offering great advantages over the manual operation when producing complicated parts due to shorter cycle times and improved quality control. It should also be noted that 5-axis milling centers require special programming knowledge since they must account for multiple cutting planes during operation, which adds another layer of complexity when setting up the program for machining operations. It is recommended that you get experienced help when setting up a 5-axis milling center program, as it may save time in the long run compared to trying it yourself if you already don’t have enough experience in this area.

Overall having a multi-axis CNC machine gives companies greater accuracy and repeatability when creating complex components compared to traditional manual machining processes while simultaneously allowing them to save time by optimizing cutting paths based on their part geometry which means faster turnaround times too! To summarize, How many axes can a CNC machine have? Depending on your application needs, you could go anywhere from 3 axes up to 5 or even 6 axes depending on your exact requirements,, but no matter what, one thing holds: having multiple Axes will give you greater flexibility with your designs which leads to improved accuracy, faster turnarounds, and ultimately better results!