[lwptoc]

What is a CNC Milling Machine

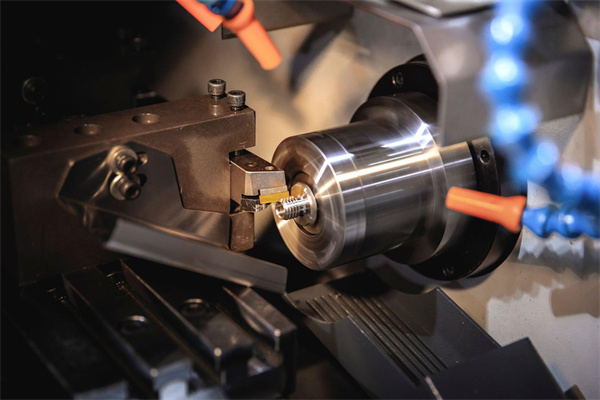

When it comes to manufacturing, CNC machining is a widely used production method. A CNC (Computer Numerical Control) milling machine is an automated and precise cutting machine that uses computer-controlled commands to fabricate objects with specific dimensions and features. This technology has been around for over 50 years, enabling manufacturers to produce highly complex parts more efficiently than ever before. But what can you make with a CNC milling machine?

CNC milling machines can produce components from any material, including steel, aluminum, brass, titanium, plastic, and composites. This means that the possibilities of what can be created are virtually endless! Everyday items made with CNCs include aircraft engine parts, automotive components such as wheels and chassis, medical instruments such as prosthetics and implants, and firearms components. Some examples of more complex products created using CNC milling machines include turbines for power plants and aerospace components.

One of the most significant benefits of using a CNC milling machine is its accuracy. With computer-controlled commands, makers have complete control over the exact shape and size they need their parts to be to ensure they match up perfectly with other components being added or removed during assembly. This precision also makes it possible to produce intricate 3D shapes that would otherwise not be achievable without having multiple separate pieces put together by hand or manually formed by other methods. Additionally, because no human hands are involved in the process, there’s less chance for mistakes, saving time and money during production.

Another advantage of using a CNC – especially compared to more traditional manufacturing processes – is how quickly things can get done. Once programmed with all the necessary commands, a CNC can finish producing parts in less time than it takes humans to do so; this speeds up lead times significantly, allowing for projects to get completed faster than ever before, giving companies an edge over their competition.

Whether you’re looking to create simple or complex objects from metal or plastic materials, a CNC milling machine is an invaluable tool for anyone involved in manufacturing or design work requiring precision down to 0.001 mm. With its ability to precisely cut 2D shapes and 3D forms at faster speeds than manual labor, it’s easy to understand why these machines have become so popular among engineers and makers alike in recent years!

How Does It Work

It’s no surprise that CNC milling machines are becoming increasingly popular in manufacturing. But what exactly are they, and how do they work? For many, these questions remain unanswered. So, if you’ve been wondering, “What can you make with a CNC milling machine?” this blog post is for you.

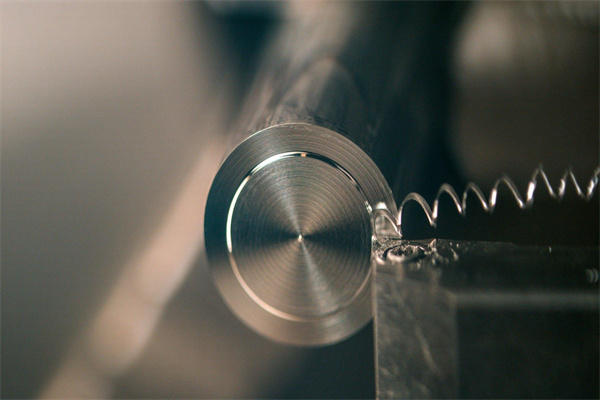

In its most basic form, a CNC milling machine is an automated cutting tool to shape materials like metals and plastics into desired shapes. This versatile machine can produce both 2D and 3D shapes – such as die stamps, orthopedic implants, and car parts – depending on the manufacturer’s or designer’s specific needs. The process begins when a computer-generated file (known as a G-code) is sent to the machine containing instructions on what kind of shape needs to be produced. The engine then uses a powerful spindle motor to turn its cutting tools at speeds up to 30,000 RPM to cut through material with incredible precision and accuracy every time.

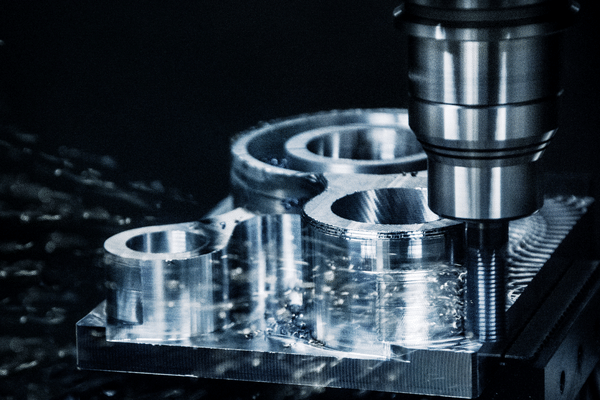

One of the main advantages of using a CNC milling machine over more traditional methods, such as manual machining, is its ability to produce complex shapes quickly and accurately without any manual intervention from an operator. This saves manufacturers money by reducing labor costs while improving product quality and consistency from batch to batch. Additionally, computer numerical control (CNC) technology has allowed designers or engineers to quickly create prototypes or test products before committing large amounts of resources to total components or parts production runs.

So what type of things can you make with a CNC milling machine? As mentioned above, CNC mills can produce nearly any 2D or 3D shape imaginable, including dieses stamps, orthopedic medical device implants, motorcycle parts, musical instruments, jewelry pieces, car body panels & engine components, electronic hardware enclosures & chassis plates – even cakes! Almost any product that requires multiple parts cut from different materials can benefit from being produced by a CNC milling machine instead of traditional methods like hand machining or stamping.

As more companies look for efficient ways to produce their goods without sacrificing quality or precision in terms of fitment and finish – it’s no wonder many have begun utilizing machines such as these in their operations today. The rise in popularity of Computer Numeric Control (CNC) technology has undoubtedly opened up an array of possibilities for manufacturers who seek greater control over their production processes and improved accuracy in results – all while reducing labor costs associated with manual machining methods. If you’ve ever asked yourself: “What can I make with a CNC milling machine?” now you know!

What Types of Materials Can Be Cut with a CNC Milling Machine

When it comes to CNC milling machines, the possibilities of what you can create using them are nearly infinite. From precision parts for medical instruments and aerospace components to large-scale sculptures and architectural pieces, CNC milling machines have revolutionized how we machine materials. So, what types of materials can be cut with a CNC milling machine?

The most common materials cut with a CNC milling machine include aluminum, steel, brass, copper, plastics, and composites. Aluminum is commonly used in the aerospace industry due to its lightweight yet durable properties. Steel is also popular due to its strength and ability to withstand extreme temperatures and high-stress levels. Brass and copper have excellent machinability, making them great for intricate parts with tight tolerances like plumbing fixtures or watch components. Plastics are fantastic for prototyping because they’re easy to shape using a CNC milling machine. Finally, composite materials such as fiberglass and carbon fiber are becoming increasingly popular in manufacturing due to their strength-to-weight ratio.

In addition to these more common materials, many out-of-the-box materials can be milled with a CNC machine. For example, some users have successfully milled plastic foam such as Styrofoam® or expanded polystyrene (EPS). This type of foam is often used in packaging products or as insulation material but can also be machined into interesting shapes with a CNC milling machine. Wood is another popular material for cutting on a CNC mill; softwoods such as pine or balsa work well, while harder woods such as maple require extra care when setting up the cutting parameters due to their ability to dull tools quickly if not machined correctly. Finally, certain types of stone can be cut on a CNC mill; from custom countertops made from quartz and marble to intricate inlaid stone floors that incorporate unique designs – just about any stone can be shaped using an adequately calibrated CNC milling machine!

No matter what you’re looking to make with your CNC milling machine, the range of available materials is nearly endless – so let your imagination run wild! With careful planning and attention to detail, you’ll soon find yourself creating beautiful works of art that previously would have been impossible without this revolutionary technology.

What Projects Can You Complete with a CNC Milling Machine

CNC milling machines are highly versatile and efficient tools for creating various products. From industrial components and automotive parts to custom jewelry and toys, CNC mills can do it all. This blog post will discuss projects you can complete with a CNC milling machine.

From precision metal parts to detailed wood carvings, the possibilities of what you can create with a CNC milling machine are endless. With our CNC software and modern technology, these machines have become even more powerful and precise. You can now easily make complex shapes with just a few clicks of a button. Here are some popular projects that you can make with a CNC mill:

1) Industrial parts: Various industrial factors can be created using CNC mills, such as machined shafts, gears, bearings, bushings, etc. These parts must be made very accurately to function correctly in the intended application. With the help of our high-grade software and advanced machinery, you can count on us to deliver accurate results each time.

2) Automotive Parts: From engine blocks and exhaust systems to pistons and crankshafts, CNC mills are used extensively in automobile manufacturing processes due to their accuracy and repeatability capabilities. The ergonomic design of these machines allows for easy operation and quick set-up times so that the production process remains efficient throughout the entire process.

3) Custom Jewelry: Creating intricate designs out of metals like gold or silver requires precision that only a CNC milling machine can provide. Our skilled artisans use these specialized tools to produce unique jewelry pieces that stand out from other traditional fragments in quality and design appeal. Whether it is earrings, necklaces, bracelets, or rings – we have you covered!

4) Toys & Models: If you’re looking for something fun yet challenging, why not try making your customized model cars or airplanes? These days most people prefer custom models over generic store-bought ones because they offer an opportunity for creativity that doesn’t exist elsewhere! Using our cutting-edge 3D printing technology combined with our experienced craftsmanship – creating intricate models has never been easier!

5) Wood Carvings: For those who enjoy working with wood – nothing beats the satisfaction of creating custom carvings using a CNC milling machine! These specialized tools allow us to carve complex shapes into different kinds of wood without any difficulty whatsoever. This means you can now access limitless possibilities when designing fine furniture pieces or even sculptures!

Overall, there’s no denying that CNC Milling Machines are potent tools capable of producing exact results each time they’re used correctly! From professional industrial components to custom jewelry pieces, the possibilities are endless when utilizing this type of machinery in your projects! So if you’re looking for something special – consider investing in one today – You won’t regret it!

The Advantages of Owning a CNC Milling Machine

You may have encountered CNC milling machines if you’re in the market for a new manufacturing tool. CNC stands for computer numerical control, and these tools are used to create precision components with accuracy and repeatability. They can be programmed to produce complex shapes in various materials, including metals and plastics. As such, CNC milling machines are becoming increasingly popular in many industries, from automotive manufacturing to aerospace engineering. But what can you make with a CNC milling machine?

The answer is practically anything! CNC milling machines can produce complex shapes that require precise dimensions, angles, and intricate patterns. This means that they can be used to create engine parts like pistons or crankshafts and medical equipment components like artificial joints and implants. Moreover, they can also be programmed to produce furniture parts like table legs or chair components. In addition, CNC milling machines are often used for prototyping and creating molds for injection molding processes. However, the advantages of owning a CNC milling machine don’t stop there. In addition to the wide range of products that can be created using this type of machinery, it also offers several other benefits. For starters, it allows manufacturers to save on labor costs since less workforce is needed when working with computer-controlled systems than when operating manual tools. Moreover, these machines also offer higher accuracy and consistency than manual tools, meaning that customers will receive better quality products every time. Additionally, these systems reduce lead times since they take less time to set up than manual machines; this makes them ideal for companies who need products quickly but still require high accuracy and precision in their workpieces.

Finally, owning a CNC milling machine offers flexibility—you can easily change your process parameters or switch from one material type to another without needing additional tools or retraining staff members on using different machinery. Plus, because these systems are so accurate and consistent in their production abilities, it’s easy for businesses to track precisely what’s been made at any given time—making inventory management more accessible than ever!

Overall, owning a CNC milling machine has many advantages over relying solely on traditional manufacturing methods: it offers higher precision and accuracy while saving time and money on labor costs; it provides flexibility in terms of switching between materials or changing process parameters; plus it makes inventory management simpler by allowing businesses to keep track of precisely what’s been produced at any given time. With all these benefits, there’s no wonder why more and more companies are turning to CNC milling machines when looking for ways to increase efficiency while still maintaining quality standards!

Get the complete solution. ↓