[lwptoc]

What is a CNC machine shop?

A CNC machine shop is a manufacturing facility that operates Computer Numerical Control (CNC) machines. A CNC machine shop offers various services, including computer-aided design/computer-aided manufacturing (CAD/CAM), 3D printing, metal fabrication, and precision machining. As a result, CNC machine shops have become an integral part of modern manufacturing operations.

At its core, a CNC machine shop is a factory where machines are used to convert raw materials into industrial parts and components for use by manufacturers in their products. Traditional CNC operations include cutting, welding, grinding, and assembly—all of which are automated processes managed by computers. In recent years, technological advances have made it possible for CNC machines also to handle intricate tasks such as engraving and milling with greater ease and Accuracy than ever before.

Computer Numerical Control (CNC) machinery has revolutionized the production process by enabling rapid prototyping and producing complex parts with Accuracy and repeatability. Advanced programming software can create components with exact specifications without human intervention or manual labor. It also allows companies to quickly develop new products since they can make changes on the fly without resetting the machine each time. This helps manufacturers save money by reducing lead times associated with traditional production methods.

The benefits of using a CNC machine shop extend beyond cost savings; it also reduces costs associated with training staff on correctly operating the machinery. Since the software controls all aspects of the process from start to finish, operators only need basic knowledge of setting up and adjusting parameters to get the best performance out of their machines. Additionally, waste is significantly reduced as CNCs can produce consistent results regardless of operator skill level since outside influences such as hand tremors or other physical factors do not come into play when using these machines.

Overall, if you’re looyou’re re precision machining services that reduce waste while helping you optimize your production process, look no further than a CNC machine shop! Their advanced technology and capabilities provide an ideal solution for cost-compelling manufacturing needs.

What are the benefits of using a CNC machine shop?

Are you in the market for a reliable, cost-effective machine shop? Look no further than CNC machine shops! CNC stands for Computer Numerical Control, and these shops offer a wide range of services that can help you produce high-quality parts quickly and accurately. From milling to turning, these machines can have complex components with a high degree of Accuracy. While there are many benefits to using a CNC machine shop, here are five of the top advantages:

1. Increased Efficiency:

CNC machine shops can create precisely machined parts in less time. By using computerized tools that allow operators to program exact movements into the machinery, production time is significantly reduced while ensuring greater Accuracy.

2. Cost Savings:

When purchasing new equipment, CNC machines can save your business money in the long run. They require very little maintenance compared to traditional methods and often have a much longer lifespan. Additionally, CNC machines can increase efficiency, resulting in lower labor costs and suitable addition of wasted material due to precision cutting.

3. Greater Accuracy:

As previously mentioned, one of the most significant benefits of using a CNC machine shop is the ability to create precise parts with great Accuracy thanks to its computerized programming capabilities, as opposed to traditional methods that rely on human operators who may not be able to consistently maintain the same level of Accuracy as an automated system, trends such as robot automation have improved manufacturing operations drastically over recent years.

4. Safer Operations:

Traditional machining processes involve dangerous tools and materials that can cause potential safety risks if incorrectly handled due to their hazardous properties (such as heat, pressure, or sparks). However, the risk of human error has been eliminated thanks to computerized programming and automated operations, allowing operators to work more safely while still producing quality results quicker than ever!

5. Versatility:

Lastly, another benefit of using a CNC machine shop is their versatility in creating different components or parts from various materials such as metals (including aluminum alloys), plastics, or composites – making them suitable for almost any product development project!

When selecting an efficient and cost-effective solution for your upcoming machining projects – look no further than CNC Machine Shops! With greater Accuracy, increased safety measures, and improved efficiency – you’ll surely succeed with this type of you’ll’llion!

How does a CNC machine shop work

A CNC Machine Shop is a specialized manufacturing facility that utilizes computer numerical control (CNC) technology to produce parts and components. CNC machines are computer-controlled, highly accurate tools used in the machining process to create precision parts with complex shapes. Using CNC has revolutionized the manufacturing industry by dramatically reducing production time, accuracy, and labor costs.

At a CNC machine shop, trained operators use CAD/CAM software to program the machines with instructions for cutting and forming metal and other materials into desired shapes and sizes. The instructions are then sent to the device and carried out as programmed. This automation allows for greater precision than is possible with manual machining methods, with fewer errors due to human hand-eye coordination or fatigue.

CNC machines can produce many products, from significant industrial components to small consumer items. Typical applications include parts for cars, aircraft, medical equipment, firearms, and more. In addition to producing individual products from raw materials such as steel or aluminum, CNC machines can be used for multi-axis operations like milling or drilling multiple holes in one go. This makes it possible for even complex parts, such as turbine blades or airplane wings, to be manufactured quickly without sacrificing Accuracy.

The benefits of using a CNC machine shop extend beyond just cost savings; they help guarantee quality assurance in production because everything runs according to plan, thus avoiding costly mistakes that could lead to product defects or rework costs down the line. Moreover, they allow manufacturers to precisely adjust specific parameters, such as speed and feed rate, throughout the process so that no part is imperfectly produced due to accidents or negligence in the operator’s position. This ensures every product from a Coperator’sr is perfect every time!

The future looks bright for CNC technology; new developments make it increasingly easy to use while providing ultra-precise results. With its broad range of capabilities and safety features—not to mention its cost savings—it’s no wonder why many businesses are turning towards Cit’st’snology for their manufacturing needs!

What are the types of machines found in a CNC machine shop?

Are you curious to find out what a CNC machine shop is and the types of machines that can be found in such a facility? A CNC (computer numerical control) machine shop is an industrial workshop specializing in fabricating and machining components for other businesses on a contractual or job-order basis using computer numerical control (CNC) machines. This blog post will discuss the various types of devices typically found within these shops.

The most common type of machine used in a CNC machine shop is the vertical milling machine, which can be used to cut metal and plastic parts. The vertical milling machine uses a rotating cutting tool known as a spindle to shape the workpiece, which can then be modified with additional tools like endmills, drills, and reamers. Some shops also have special attachments allowing them to perform more complex operations such as boring holes or grinding surfaces.

Other popular CNC machines include lathes, horizontal mills, and 3D printers. Lathes are often used for creating complex shapes from metal or plastic material by turning it around its axis while applying cutting tools. Horizontal mills are commonly used for larger-scale machining jobs, while 3D printers allow for rapid prototyping of small and intricate parts with precision accuracy.

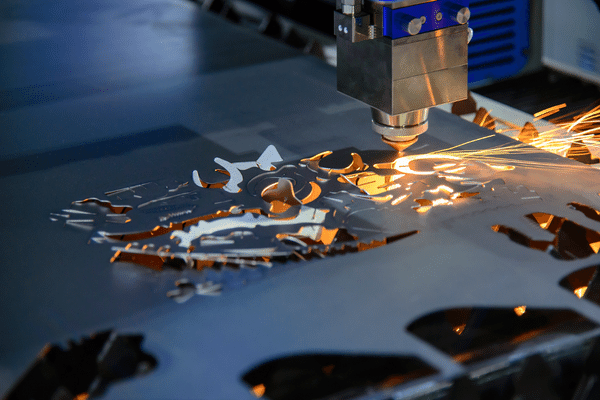

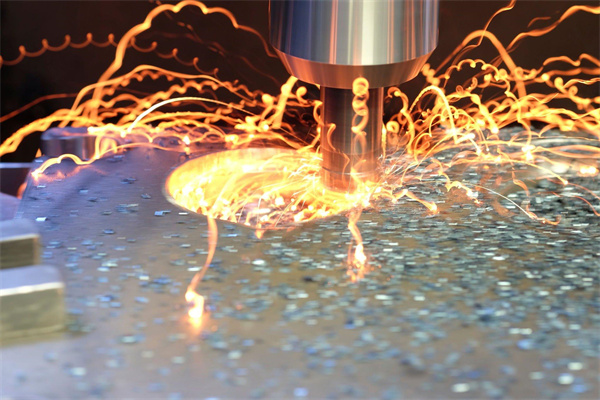

In addition to these standard equipment pieces, other specialized machinery types are available such as EDM (electrical discharge machining) systems, laser cutting systems, and waterjet cutters. EDM systems use electric sparks to cut metal parts without physical contact between the cutting tool and the material being cut; laser cutting systems utilize high-powered beams of light to make precise cuts; while waterjets use jets of pressurized water with abrasive particles suspended within it to slice through hard materials like steel or titanium with minimal heat affected zones (HAZ).

Before making any significant investments into these advanced pieces of equipment, however, it is essential to understand the needs of your business first and then make an informed decision on what type is right for you. This way, you can ensure you have all the necessary tools available so your shop can efficiently produce quality parts at competitive rates while still staying profitable.

To conclude, CNC machine shops are invaluable resources for businesses that need custom-made components produced quickly and accurately without costly delays or errors. Various machines are available in these workshops ranging from simple manual lathes to sophisticated EDM systems, each offering unique advantages depending on your specific production application needs. With proper training and operation knowledge, you can rest assured that your shop will be able to produce high-quality results every time!

The advantages of using computer numerical control for manufacturing

Today, the manufacturing industry has increasingly relied on computer numerical control (CNC) machines for production. CNC machining is a process that uses computer-controlled devices to shape and cut raw materials into products. This technology allows manufacturers to produce products quickly, accurately, and cost-effectively.

One of the most significant advantages of using CNC machining is its speed and precision. CNC machines can be programmed to execute complex commands with great Accuracy, allowing for consistent results that are difficult to achieve through manual fabrication methods such as drilling or cutting by hand. This precision is also helpful when creating complex shapes and components where minute details must be repeated precisely across multiple pieces. Furthermore, this automated process reduces the risk of human error, which can lead to costly reworks or even scrap parts in some cases.

Using CNC machines also enables companies to save time and money. Automating processes that were once manually performed significantly reduces labor costs as fewer workers are needed to manage the machinery during production runs. Furthermore, since these machines do not require rest periods between shifts as people do, they can operate nearly nonstop with little maintenance downtime needed in between changes. This allows manufacturers to maximize their output while keeping operating costs low at the same time.

Moreover, CNC technology allows manufacturers to create highly complex components with a wide range of materials, such as metals, plastics, composites, and more, without causing any damage or compromising product quality. With an automated system, there’s no need for manual adjustments or sanding down materiathere’ses after machining, which increases the efficiency of your production process even more.

What is a CNC Machine Shop? A CNC machine shop is a facility where machines controlled by computer numerical control (CNC) technology produce goods from raw materials such as metals, plastics, or composites according to customer specifications. Such shops typically feature tools such as lathes, milling machines, drill presses, and grinders – all equipped with sophisticated software and hardware for programming the exact cutting paths needed for each part produced in this facility. By having access to a well-equipped machine shop that offers high-precision services on short notice, you can quickly reduce your overhead costs while maintaining exceptional product quality at all times!

In conclusion, CNC machining has revolutionized modern manufacturing processes by providing efficient methods of producing highly accurate components quickly and cost-effectively compared with traditional fabrication techniques requiring manual labor input. As technology advances in this area, we will likely see even higher levels of efficiency attained through automated processes powered by CNC systems making them even more attractive options than they already are today!