[lwptoc]

What is a CNC machine, and what does it do?

A CNC machine is a computer numerical control tool that precisely cuts and shapes plastic, wood, metal, and other alloys. CNC machines are programmed using computer-aided design (CAD) software that inputs instructions for the machine to follow to complete its assigned task.

CNC machines have been around since the 1950s but have become an increasingly popular choice for manufacturers due to their endless possibilities and accuracy. They can quickly create complex shapes from various materials with minimal manual labor, making them ideal for mass production.

Defining your project goals is the first step in setting up a CNC machine. Once you’ve determined what to achieve with the machine, you must choose a suitable material and create a 3D model of your desired object in CAD software such as AutoCAD. You will then input this data into the CNC machine’s control panel, guiding it through the steps necessary to produce your product.

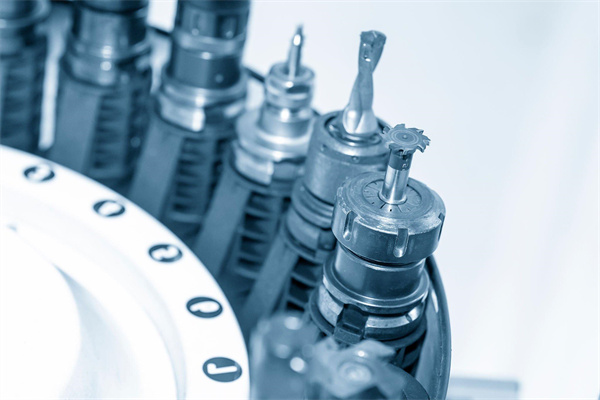

Once your object has been designed and loaded into the control panel of the CNC machine, you can start running it. Some devices may require different tools or processes depending on the cut material. For example, cutting aluminum may need a router head instead of a drill bit because it is more effective with softer metals like aluminum and brass.

Once everything has been set up correctly and all safety protocols are observed, operators can run tests on the machine before beginning production. Ensuring all settings are correct before starting production runs is essential to provide quality products at maximum efficiency levels.

CNC machines give manufacturers significant advantages, such as increased accuracy and precision when manufacturing parts compared to traditional methods like hand-cutting or milling machinery. The speed at which they operate also means that fewer workers are required during production runs which can help reduce overall labor costs while still maintaining high-quality standards across products produced by the company.

Overall, CNC machines offer unparalleled versatility in producing intricate parts in various materials quickly and efficiently without sacrificing accuracy or quality of artistry along the way! With proper setup and maintenance procedures in place, these tools can be highly beneficial for any business looking for efficient ways to increase their output without compromising product quality!

How do you set up a CNC machine in your shop or garage?

Setting up a CNC machine in your shop or garage can be intimidating for many. But with the proper knowledge and tools, you can have your computer numerical control (CNC) machine up and running quickly and easily. In this blog post, we’ll discuss setting up a CNC machine in your shop or garage, focusing on your needed tools and the most critical steps.

First, you’ll need to determine what type of CNC machine best suits your needs. Do you want a 3-axis or 4-axis machine? A router or milling machine? For hobbyists, 3-axis machines are often the most popular choice due to their simplicity and affordability. Milling machines are typically better for precise cutting work but are more expensive than routers.

Once you’ve chosen the type of CNC machine that’s best for you, it’s time to start setting it up. You’ll need some essential tools, including a socket wrench set with metric sockets, screwdrivers of various sizes, an Allen key set, pliers, and wire cutters/strippers if necessary. You may also want a soldering iron for making electrical connections when wiring the controller board on specific machines.

Next comes the assembly of the physical components: mounting the frame pieces together securely with screws and bolts; connecting the stepper motors; attaching power cables; and connecting other wires, such as limit switches if applicable. Depending on the model and type of CNC machine you purchased, instructions should come with it that will give step-by-step instructions on assembling it correctly—be sure to read through these instructions carefully!

Now that everything is assembled correctly, one of the most important steps is setting up software drivers. This step can be skipped if your CNC machine has installed software drivers. Otherwise, you’ll need to install them yourself before moving on to the setup of any accompanying CAM or CAD software required to operate your new CNC machine. Again, installation instructions should come with your particular model, so ensure those are followed closely during this step!

Finally (but certainly not least), calibrate your new CNC machine carefully before use so that everything is aligned perfectly for maximum accuracy when cutting materials later on. This includes leveling all axes properly using adjustable feet (if included); checking all belts are tight enough without being too close; making sure all stepper motors move freely in both directions without binding; double-checking all electrical connections; and verifying good contact between metal parts such as motor shafts during movement tests as well as ensuring correct thread engagement.

Setting up a CNC machine in your shop or garage doesn’t have to be complicated—with careful planning ahead of time plus following detailed instruction manuals supplied by manufacturers closely during assembly and setup afterward, anyone can get their computer numerical control (CNC) system working quickly and accurately in no time at all!

What are the benefits of using a CNC machine for DIY projects or business purposes?

Using CNC machines can be highly advantageous when completing DIY projects or running a business. CNC stands for “Computer Numerical Control” and refers to a machine that operates with instructions provided through digital code. This enables the device to automate tasks, meaning they can swiftly produce items with precision, accuracy, and repeatability. Setting up a CNC machine requires some knowledge and skill. Still, the benefits can be invaluable once you unthe benefits can be invaluable derstand how they work main advantage is that CNC machines can produce products with higher accuracy than other manual methods, such as dr, k, k,illing, or milling by hand. This is because the machine allows precise control over its movements due to its programming capabilities. With this increased accuracy, you can create products with exact measurements and fine details, which are difficult to achieve manually. Additionally, since CNC machines can execute intricate designs in shorter time-frames than other methods, this drastically reduces production costs and speeds up production times.

Another benefit is that CNC machines have excellent repeatability – meaning that once a program has been inputted into the system, it will consistently produce duplicates of the same item without any errors or variations in quality each time. This makes them ideal for creating multiple copies of complex pieces quickly and efficiently without worrying about inconsistencies between each product. Furthermore, CNC processes are safer than manual ones since they require less human interference throughout their operation, which helps reduce risks posed by potential accidents during manual labor operations.

CNC machines also offer immense versatility regarding what materials can be used – from plastics to metals, wood, and more – many different types of materials can be worked on using CNC technology with ease. Moreover, they provide less waste material due to their high precision cutting capabilities, making them much more cost-effective and allowing users to use all available resources during production runs instead of wasting excess material due to imprecise cuts from manual machinery or tools.

Overall, setting up a CNC machine may take some time, but the result offers an array of benefits for both DIY projects and business purposes alike; from greater accuracy and repeatability; reduced production costs; improved safety measures; a more comprehensive range of materials available for use; less waste material produced compared with other techniques – these all add up allowing businesses or individuals looking for an efficient way to manufacture parts or products an ideal solution at their fingertips!

What types of materials can be machined with a CNC machine?

When it comes to machining, a Computer Numerical Control (CNC) machine is a powerful tool for producing precision parts and components. This type of machine is used across multiple industries, from automotive to aerospace, because it provides high accuracy and repeatability in every job. But what kinds of materials can be machined with a CNC machine?

The answer depends on the type of CNC machine being used. For instance, some devices are better suited for milling metals, while others can animate designs into wood and other materials. CNC machines generally work with rigid materials such as aluminum, steel, brass, titanium, ABS plastic, etc.; they can also work with softer materials like foam or wax when using the right cutting tools.

In addition to the material, a CNC machine must consider several other factors. For example, the cutting speed must match the material type – cutting too quickly can cause heat buildup and damage the tool or material. At the same time, Cutt, ing too slowly will take longer than necessary and increase production time. The feed rate needs to be adjusted correctly as well; if it’s set too high, it can lead, d to poor quality or quality if i’; if, it can cause, see excessive wear on both the tool and material.

Tool selection is also important; essential tools generate different amounts of heat during operations, affecting fish, quality and cut depth accuracy. The flute length should also be considered based on material thickness; longer flutes allow for deeper cuts but require more power from the spindle motor which decr, which d, d,ecreasing the tool’s and machine’s life expectancy after all these considerations have been appropriately addressed. You’ll need to ensure that your CNC program is configured correctly, including items such as tolerances, finishing strategies (roughing vs. finishing .passes), tool paths, etc..… Once all … parameters are adjusted correctly; you should be ready to begin machining your project!

Overall, setting up a CNC Machine for any app requires careful planning and attention to detail without damaging the equipment or itself. It’s essential to keep in mind that not all materials will work with every kind of CNC Machine – depending on your project requirements you may be, ed specific settypeetup types of parameters for it to run smoothly, so always, double checdouble-checkrting job!

How to use CAD software to create designs for machining

Creating parts through machining is a precise process that requires a great deal of technical knowledge and skill. As such, using it to develop des develpsdevelop machining can be an invaluable tool, allowing experienced professionals to build coproducproducers more quickly and accurately than ever before.

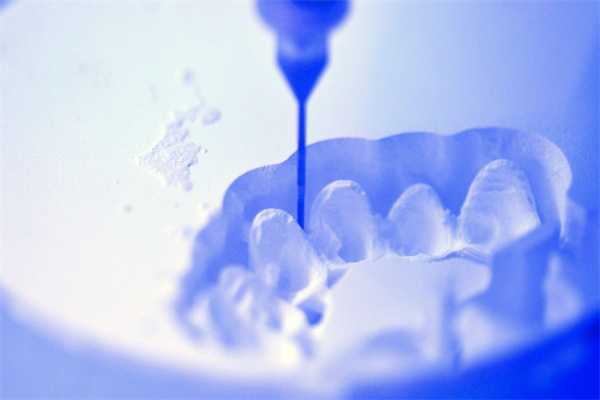

CAD software is essentially computer-aided design (CAD) software that helps users create 3D models and blueprints for manufacturing. This type of software allows users to design complex shapes, curves, and other features that would otherwise be impossible or time consumtime-consumingby hand. With advanced tools like parametric modeling, users can easily adjust their designs with just a few clicks of mouse clicking cred in CAD, and CNC maCNC machining operations can then be used to machine specialized computer-controlled machines used from metal or plastic blocks into custom shapes as specified by the designer’s digital design files. The digitized data is then sent directly to the CNC machine for production. This eliminates much of the guesswork involved in traditional manual machining operations and ensures that each part produced is identical to the original design.

Although some basic knowledge of CAD may be required before attempting to use this type of software for creating designs for CNC machining, most CAD packages come with comprehensive tutorials and guides on how to get started. Many packages also offer features such as si and si I simulations, which help users visualize how their designs will look once they are cut into parts by a CNC machine.

In addition, many online resources provide expert advice on using various CAD packages to create creative CNC machining operations. These resources often include step-by-step tutorials and hands and tricks on making the most out of specific CAD packages when designing components for CNC machines.

Ultimately, using CAD software has revolutionized how many manufacturers approach designing components for their projects, making creating complex parts easier than more accessibleccessible before. It enables experienced professionals to save both time and money by ensuring accuracy throughout their manufacturing processes while producing superior results every time.

Tips for troubleshooting common problems with CNC machines

As CNC (Computer Numerical Control) machines become more common across different industries, it’s important to understand how to set up and troubleshoot these powerful tools. Setting up a CNC machine can be a complex process that requires careful planning and attention to detail. However, it doesn’t have to be an intimidating task with the right know proper.

Understanding its physics is one of the essential criticisms of letting up a CNC machine. This includes becoming familiar with various com such as linear guides, ballscrews, motors, spindles, servos, and drives; once you know the mechanics of the machine, you can move on to programming the machine using G-code (the language of CNC machines).

It’s also important to make sure the tensureomponents of your CNC machine are properly ca adequately calibrating for the first time. This includes verifying that all axes are level and aligned with each other and ander lubrication in each joint and gear. Finally, double checdouble-checktions within your system before powering it up—even one faulty cable or wire could cause serious proseverseversevereown the line!

Once you have successfully set up your CNC machine, there will inevitably be times when something isn’t working correctly or needs maintenance. Troubleshooting can help identify potential causes for any issues that arise during operation. Common problems associated with Chinese include malfunctioning drives, motion errors due to misalignment or calibration issues, and wear and tear on various components over time.

No matter what problem you run into when troubleshooting a CNC issue, there are several steps you should take:

1) Verify that all necessary connections are secure

2) Check for any physical obstructions or loose parts near the affected area of your machine

3) Inspect any electrical wiring for signs of fraying or corrosion

4) Review any applicable error codes or diagnostic messages

5) Consult the manufacturer’s manual for specific instructions on how to resolve particular issues with your model CNC machine

Finally, if these measures do not solve your problem quickly and efficiently, contact technical support from your manufacturer; they may be able to offer additional guidance, which may prove invaluable in fixing any major problsignificantficantficantith your system swiftly and effectively.

In conclusion, setting p and troubleshooting a CNC machine requires thorough knowledge of its mechanics and attention to detail when programming and calibrating. Following the tips outlined above should help ensure that these complete tools remain reliable contributors to any production line!