[lwptoc]

What materials can a CNC machine cut

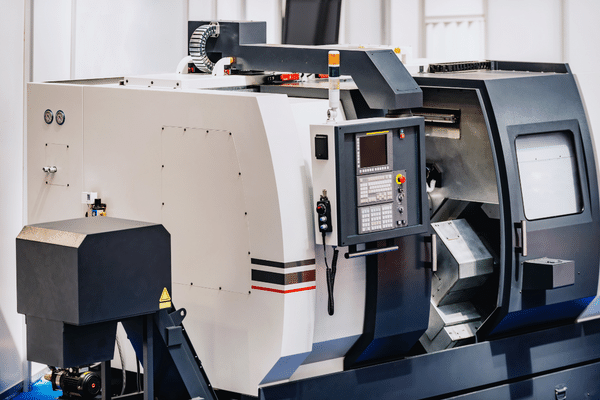

A Computer Numerical Control (CNC) machine is an automated tool used to cut and shape materials with precision and accuracy. CNC machines are commonly used in the manufacturing and engineering industries for various applications, such as producing parts for aircraft or automobiles, creating molds and dies, and fabricating components from composite materials. While the types of materials that can be cut with a CNC machine vary depending on the size and complexity of the project, there are many common materials that this type of tool can successfully machine.

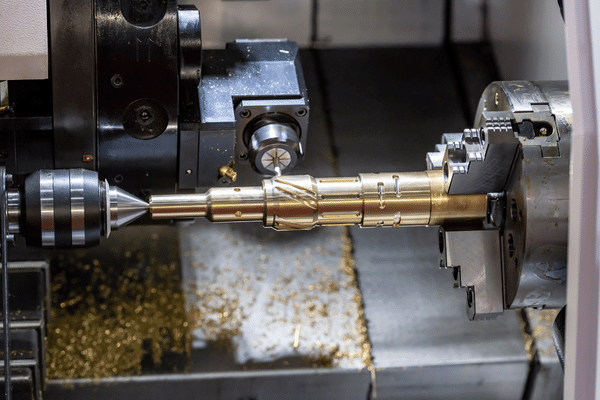

Metal is one of the most popular materials to cut by a CNC machine. Metal is strong, durable, and relatively easy to shape using a CNC machine’s numerical control system. Aluminum is an especially popular material for machines due to its malleability and ability to retain its form when exposed to heat or pressure. Steel is also frequently machined using CNC machines since it retains its shape after being cut or molded. With these two metals combined, almost any component imaginable can be crafted using a CNC machine.

The other prevalent material used in CNC machining is wood. Wood comes in many forms: hardwood, softwood, plywood, MDF board, etc., all of which can be effectively shaped using a CNC router. The advantage of woodworking with a CNC machine over traditional methods like sawing or sanding is that the edges come out much smoother with fewer chances for human error or inconsistencies in the overall product design. For furniture makers especially, this makes it easier to achieve desired results in terms of both looks and feel than would otherwise be possible by hand-crafting each piece separately.

In addition to metal and wood components, CNC machines can handle various plastic materials such as acrylics, polycarbonates, and even nylon composites. Of these three materials, acrylics offer exceptional clarity. At the same time, nylon composites provide superior strength without sacrificing flexibility—an ideal combination for prototyping parts like blades or gears where durability and lightness are important factors. Lastly, polycarbonate plastics are highly resistant to impact, so they’re popularly used in projects involving impact-sensitive objects like medical instruments or phone cases.

In conclusion, no matter what kind of project you’re planning on taking on—from prototyping mechanical components to creating custom furniture—a Computer Numerical Control (CNC) machine will likely give you the best results when cutting metal, wood, or plastic materials alike! With their precision cutting capabilities, speed, and accuracy compared to manual tools, it’s no wonder why more manufacturers have started relying on these automated tools for industrial-level projects.

The benefits of using a CNC machine to cut materials

The use of CNC machines in material cutting has become increasingly popular in recent years due to the many benefits they offer. In this blog post, we’ll explore the advantages of using a CNC machine for cutting materials and discuss what materials can be cut with it.

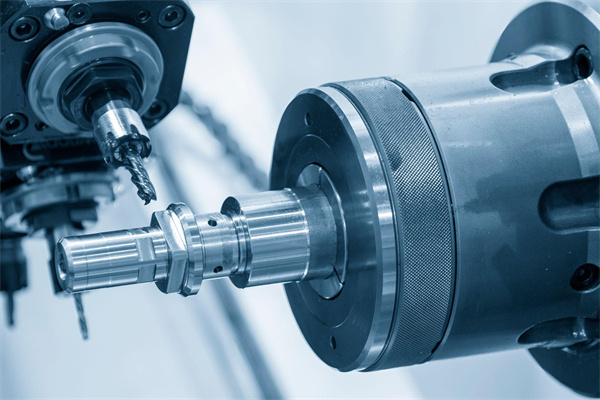

CNC stands for Computer Numerical Control, meaning that the machine is controlled by a computer using numerical commands. This allows for accuracy and precision when cutting materials, one of the main advantages of using a CNC machine. With its advanced technology, CNC machines can make cuts with extreme precision while providing more consistency than manual methods. This makes them ideal for applications where high precision and repeatability are essential, such as aerospace or automotive manufacturing.

Another advantage of using a CNC machine for cutting materials is its versatility. It can be used to cut materials of different shapes and sizes without needing to be adjusted. The machine can also easily handle complex geometries, allowing manufacturers to quickly and accurately create intricate patterns on parts or components quickly and accurately. Additionally, some modern CNC machines have been equipped with automated tools that allow them to switch from one material to another without needing manual intervention.

When it comes to what materials can be cut with a CNC machine, the answer is almost any material imaginable. From metal alloys like aluminum and steel to plastics such as polyethylene and PVC (polyvinyl chloride), CNC machines can process a variety of different materials in both thick and thin forms. Additionally, many modern machines support soft metals such as copper and brass and hardwoods like oak and cherry wood.

In conclusion, there are many benefits to using a CNC machine for cutting materials due to its high accuracy and precision and its versatility in processing different types of material. Its automated features make it easy to switch between different types of material quickly while remaining precise in operation throughout the entire process, making it ideal for industries such as aerospace engineering or automotive manufacturing where accuracy is key.. Whether you are looking for high levels of accuracy or speed when processing your material, using a CNC machine will help you achieve your goals faster than ever before!

How to choose the right material for your CNC project

Choosing the right material for a CNC project is one of the most important decisions in the manufacturing process. By selecting the appropriate material, you can ensure that your CNC projects are high-quality and safe. The type of material you choose will depend on what you want to achieve with your CNC project – whether a prototype, a production item, or even an art piece.

Before selecting the right material for your CNC machine, there are several factors to consider: cost, availability, and compatibility with your software and hardware tools. It’s also important to know what materials a CNC machine can cut. With so many choices available, it’s easy to get overwhelmed by all the options available. To make things easier, we’ve outlined some commonly used materials and their ideal applications below.

Wood

Wood is one of the most popular materials used in CNC projects because it is relatively inexpensive and easy to work with. Wood is perfect for making prototypes or sculptures as it can be machined precisely with minimal sanding and finishing required after completion. You can use softwoods (such as pine) and hardwoods (such as walnut) with a CNC machine, but remember that hardwoods are more difficult to cut than softwoods due to their greater hardness level. Common woods, such as cherry, maple, and oak, can easily be machined with a CNC router or spindle tool.

Plastic

Plastic is another commonly used material in CNC projects because of its strength and durability when machined properly. Various types of plastics can be used in various applications – from signs to models – depending on their strength and appearance requirements. Some examples include acrylics (PMMA), polycarbonates (PC), polypropylene (PP), and PVC foam board Sheet materials for laser cutting & laser engraving, etc., which come in different shapes and sizes according to individual projects needs; these plastics have excellent cutting characteristics which helps hold intricate detail during the machining process。

Metal (Aluminum/Stainless steel / Titanium )

Metals such as aluminum, stainless steel, or titanium are often used in CNC projects due to their strength and durability when machined properly. They require more powerful tools than other materials but offer great results if done correctly. Metal parts produced using a CNC machine have precise dimensions, which are extremely helpful when creating precise prototypes or production parts。 Aluminum is lightweight while stainless steel has better corrosion resistance, and titanium offers excellent rigidity yet lightweight properties; Each metal provides different features suitable for different applications, so understanding what each metal offers before selecting one is important。

Recommend reading:

Foam(Foam Core & Polystyrene Foam Board)

Foam core board is popularly used as well when producing artwork, especially those involving intricate details such as logos or designs。 It’s lightweight yet strong enough when cut correctly by hand tools or machines, which means minimal post-processing is needed after cutting。 Polystyrene foam boards provide good insulation properties due its low thermal conductivity, making them an excellent choices for prototyping architectural models etc。 Both these foams are easy to work with but produce dust particles during the cutting process, making cleaning up afterward an essential task。

Glass

Glass may not always be considered the first option when deciding on a material for Machining, but its characteristics make it a practical choice, especially where strength, transparency, etc., .is required。 With correct tools like diamond-coated drill bits, glass can also easily be machined without worrying about cracking due to excessive heat build-up during the drilling process、Glass parts produced using CNC machines help designers create stunning art pieces combining both light refraction effect along beauty precision cutting allows achieving。

Ceramic

Ceramic is increasingly being used more often in creative works thanks to its unique characteristics allowing the creation of beautiful art pieces; however, they require very specialized equipment like a diamond-coated saw blade, etc ..to achieve desired results without damaging ceramic itself since ceramic cannot tolerate temperature changes related sudden stops during cuts process、Using cnc mills also very useful technique producing highly accurate parts makes preferred ceramic choice many designers who are looking something special.

Choosing the right material for your project involves carefully considering factors such as cost, availability, and compatibility with your software/hardware tools – all while keeping in mind what materials a CNC machine can cut precisely without wasting time or resources! Each project will require different materials depending on its purpose – from functional items made out of wood or metal to artistic creations made from plastic foam glass ceramics. As long you understand each material’s capabilities and limitations, it’s possible to create amazing pieces using CNC technology while ensuring safety throughout the entire process.

Examples of projects that can be made with a CNC machine

The CNC machine is a powerful tool used across many industries, from carpentry to manufacturing. It offers tremendous value and versatility when it comes to producing a variety of products. Using Computer Numerical Control (CNC) technology, the operator can quickly create a precise output without extensive manual labor.

When looking at examples of projects that can be made with a CNC machine, there’s no limit to what you can do. From complex aircraft components to intricate wooden sculptures, CNC machines can produce high-quality results on various materials. This makes them ideal for creating prototypes or production runs in various industries, including automotive, aerospace, medical devices, and more.

One of the most important decisions you need to make when considering which projects to make with your CNC machine is what materials can be cut with it. While some materials are easily cut by CNC machines (e.g., aluminum and mild steel), others may require additional steps or even specialized tools for the best results. Common materials that can be cut or machined include plastics, wood, composites, brass, and titanium alloys. Different end mills may be required for optimal performance depending on the type of material you are working with; if in doubt, consult an expert or manufacturer recommendations before beginning any project.

In addition to understanding the types of materials your CNC machine can cut, it is also important to consider its accuracy and repeatability when planning any project. This information should be readily available in the product documentation provided by the manufacturer; if not, it is worth asking an expert to ensure that your desired outcomes are achievable with the available equipment. An example could be trying to produce intricate carvings on softwood – even though this material is relatively easy for a CNC machine to handle, it will require careful setup and regular maintenance for accurate results every time.

Finally, when creating projects with a CNC machine, safety should always come first; ensure you have installed proper guards and read up on safety precautions before starting any job, as mistakes could seriously injure or even kill an operator if precautions are not taken seriously! Always wear protective gear such as gloves and goggles while operating any machinery – no matter how small – as loose clothing or jewelry could easily get caught in moving parts resulting in serious injury or death.

In conclusion, understanding what materials can be cut by your CNC machine is key when deciding which projects you want to take on using this powerful tool – whether it’s producing car parts or small home goods like wooden sculptures – the possibilities are truly limitless! With the right setup and knowledge base, you’ll be able to safely turn out high-quality products quickly and efficiently every time – so why not put your newfound wisdom into action today?

Tips for working with different types of materials

Working with different materials can be daunting for many makers and designers. Knowing which materials you should use for a project and how to ensure that your projects are of the highest quality can be difficult to figure out. Fortunately, CNC machines can make this process much easier. With their precision cutting ability, these machines can easily cut through a wide range of materials, allowing you to quickly and accurately create the desired results without worrying about mistakes or substandard artistry.

So, what materials can a CNC machine cut? The answer is more than you might think! CNC machines can cut through wood, metal, plastic, foam, and many other materials. For example, suppose you’re looking to produce aluminum or steel sheet metal parts. In that case, CNC milling is ideal as it allows you to achieve detailed shapes that would otherwise be impossible using more traditional methods. Similarly, CNC routers provide the accuracy required for intricate designs and complex curves that would otherwise be impossible when working with wood or other softer materials like foam or plastic.

Get the complete solution. ↓

When working with any material on a CNC machine, selecting the right type of tooling for the job is important to ensure successful results. For instance, when cutting metals such as aluminum or stainless steel, high-speed steel (HSS) end mills are typically used for their durability and ability to maintain accurate dimensions at high speeds. On the other hand, softer materials like plastics or wood carbide-tipped tools are often recommended due to their lower cutting forces, allowing them to produce cleaner cuts with greater accuracy at faster feed rates than traditional HSS tools.

In addition to selecting the right type of tooling, it’s important to consider your material selection carefully, depending on what results you require from your project. While most metals can be cut with relative ease on a CNC machine, there are some limitations depending on its size and configuration; too thick a metal plate may require additional supports so it does not buckle during machining operations, while thinner sheets may need additional rigidity provided by a backing board to avoid warping under pressure from the tooling. Selecting the wrong type of material could lead to issues during Machinings, such as chatter marks or breakage. Hence, it’s always important to research beforehandmine what material is best suited for your project before beginning work on your design in CAD software, such as Fusion 360 or Autodesk Inventor.

Finally, when setting up your material for machining, all edges must be deburred before to avoid snagging during cutting operations which could cause unwanted damage not only to the part being machined but also potentially harm both the operator and machine alike! To deburr correctly, use either an abrasive wheel such as those found on bench grinders/deburring machines, or, fine sandpaper wrapped around smooth flat blocks will also suffice. However, this method may take longer than its mechanical counterpart depending on how much burring needs doing – professional operators recommend taking care here as trying rush jobs could result in unsatisfactory results!

Overall, understanding what materials can be cut using CNC machines makes creating complex shapes quicker and easier than ever! Whether you’re making parts out of aluminum sheet metal or intricate wooden models, they will always deliver precise results without fail, allowing designers & makers everywhere to bring even their wildest ideas into reality!