In the present day, there are numerous industries that use CNC (computer numerically controlled) machines. The main aim of these machines is to carry out certain tasks quickly with accuracy without any human intervention. Here, in this blog, we take a close look at the CNC tools.

What Are the CNC Tools in Industrial Electronics?

CNC tools are used in industrial electronics. CNC stands for “Computer Numerical Control,” and the term refers to a method of controlling machines that allows for higher levels of automation than other methods. These tools are used in many different industries, including aerospace engineering and electronics manufacturing.

CNC tools include:

CNC machine tools: These are large machines used for cutting or milling materials with precision, often to exact specifications set prior to the start of a job. They can be used on metal, plastic, or wood, and they have multiple axes of motion so they can cut more than one surface at a time.

CNC routers: These machines use a router bit at high speed to carve out shapes from hard materials like metal or stone.

CNC lathes: Lathes turn metal into various shapes by spinning them against an abrasive surface in order to remove material from the outside of the piece being worked on until it reaches the desired shape.

Why Are CNC Tools Used?

CNC tools are used in a number of industries to help with production and manufacturing. CNC stands for Computer Numeric Control, and these machines can be used to create any type of product. The most common types of CNC tools are milling machines, lathes, and 3D printers.

CNC tools have been around since the 1950s when they were first used to create machine parts. Today, they’re used in almost every industry that involves manufacturing or creating products.

Why Are CNC Tools Used?

CNC tools are used to create a variety of different products including:

Machined parts – These can include things like gears and other mechanical parts that would require a lot of time if done manually.

Industrial electronics – With the advancement of technology, it’s now possible for CNC machines to create electronic circuit boards for various devices from computers to smartphones.

Automotive parts – This includes items such as engine blocks, transmission cases, and more which are often made from metal alloys that need to be cut into specific shapes using a milling machine or lathe.

How to Choose the Right CNC Machine Tools?

Choosing the right CNC machine tool is a big decision. It’s also an investment that will pay off over time as you use it to create products that are more accurate and consistent than those produced by manual methods.

There are a number of factors to consider when buying a new machine tool, but here are some questions you should ask yourself before making a final decision:

The first thing to consider when choosing a CNC machine tool is how much work you will be doing. If you are just starting out, or if you are looking for something for hobby use, then a smaller machine is probably best.

A smaller machine will be easier to learn on and cheaper to buy and maintain. However, if you know that you want to do more than just the occasional project, then it may be worth investing in a larger machine that can handle heavier loads and bigger projects.

If you are buying a used CNC machine, make sure that it has all of its original parts before committing to the purchase. The parts most likely to break down over time are the motors and the bearings. These items have been known to fail after just a few years of use if not properly maintained.

If buying new, ask about maintenance contracts when purchasing any CNC machine tools from someone other than an authorized dealer. This way you will get support when needed without having to pay full price upfront for service calls or replacement parts right away.

What Are the Uses of CNC Tools in Industrial Electronics?

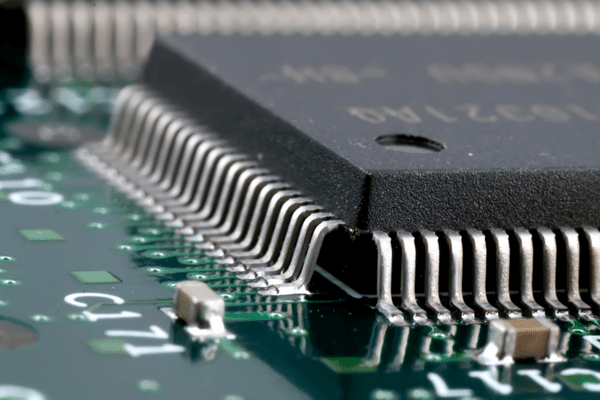

CNC tools, or computer numerical control tools, are used for industrial electronic manufacturing. A CNC tool consists of a workstation and all of the necessary hardware (sensors, motors, and controllers) that allows it to perform its assigned task. The workstation is made up of a computer or PLC (programmable logic controller) with a graphical user interface (GUI).

CNC tools are used to create parts for many different industries including:

Automotive: CNC tools are used in the automotive industry to create parts such as brake discs and pistons. They can also be used to manufacture other car parts such as engine blocks and transmissions.

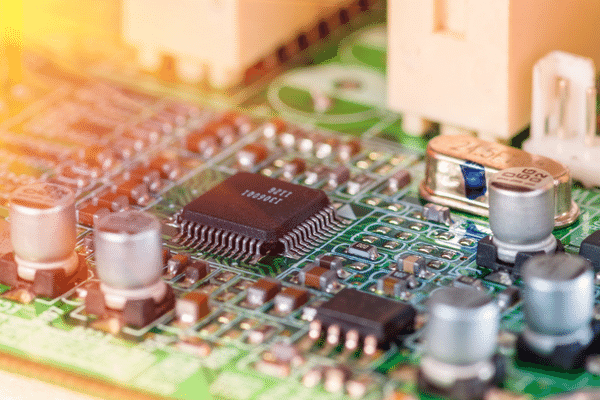

Electronics: CNC tools are commonly found in electronics manufacturing facilities where they manufacture circuit boards and other electronic components. These machines have been designed to create high-quality products with minimal errors.

Medical: CNC tools have been heavily used in the medical industry since their inception. These machines can be found in hospitals across the world performing tasks like sheet metal cutting, CNC Boring, and cnc machining screws.

What Are the Features of CNC Tools in Industrial Electronics?

CNC tools are used for industrial electronics. They can be used in the production of electronic products and devices such as computers, mobile phones, and other devices.

The CNC tools perform a number of functions that include cutting, drilling, milling, and more. This makes them very important in industrial electronics.

The following are some of the features of CNC tools in industrial electronics:

1. High accuracy: The high-precision machines have the ability to cut and drill with precision. The machine has been designed to ensure that it can perform tasks with high accuracy so as to ensure that any product that is manufactured using this tool is of high quality.

2. Durability: The machine is durable and will not break easily even after being used for many years without maintenance or repair work being done on it by an expert technician or engineer who knows how to use CNC machines well. You need not worry about having problems with the machine breaking down because it will always be there for you when you need it most!

3. Speed: A good machine should be able to cut or drill faster so as to reduce production costs and also save time which means you don’t have to wait a long time to get your product from the factory using these machines.

What is the Application of CNC Machine Tools in Edm Machining?

CNC machine tools are computerized machine tools that are used to produce items with a high degree of accuracy. The machines can be programmed to perform the same task over and over again, making them useful for mass production.

The CNC stands for computer numerical control and is used in the manufacturing industry to control the operation of CNC machine tools.

CNC machine tools are used for a variety of applications, including but not limited to:

-The production of parts for automobiles and other vehicles.

-Medical devices (such as pacemakers).

-Electronics (such as cell phones).

-Industrial equipment (such as turbines).