[lwptoc]

What is CNC machining, and what does it involve

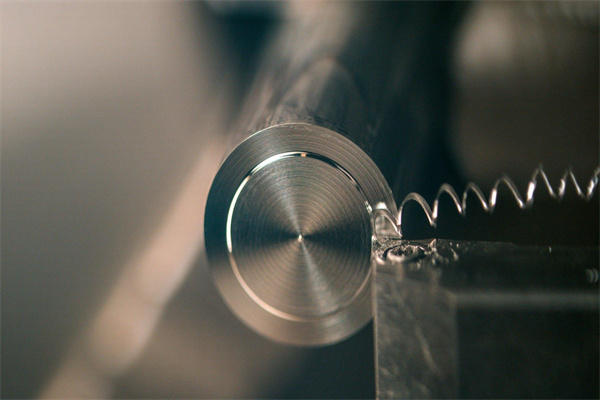

CNC machining is a manufacturing process that utilizes computer numerical control (CNC) machinery to shape, create and form products. Technology was introduced during the industrial revolution, allowing machines to be used more efficiently and accurately. CNC machining has become invaluable in many manufacturing industries, including aerospace, automotive, medical device, electronics, and many others. It can produce components of any complexity with great accuracy and repeatability.

So what exactly does CNC machining involve? In short, it involves two main steps: programming the machine to manufacture the product and running the program on the machine itself. Programming is done by entering instructions into a computer program that tells the machine how to move its tools around to cut or shape the material into precise shapes and dimensions as specified in the design. Once programmed correctly, this process can be repeated with great accuracy and repeatability.

The machining process involves various cutting tools, such as drills, lathes, mills, and routers. These are then used to cut away material from a workpiece to achieve a desired shape or size. These tools are usually attached to a robotic arm that allows for precise motion along three axes so that complex shapes can be achieved quickly and accurately. The time it takes for a given project depends on its complexity and factors such as feed rate (how fast material is being removed) and several passes (how many times a cutter is used).

When it comes down to it, CNC machining offers some incredible advantages compared with other forms of manufacturing processes; however, there are also some drawbacks associated with it too. For example, since all operations need to be pre-programmed manually before the machine can carry them out, this can lead to long setup times whenever changes have to be made, or new parts need to be produced, something is known to drive up costs significantly.

Additionally, high-precision results cannot always be ensured due to inherent limitations in both hardware & software components involved in these systems; This means certain tolerance levels still need to be considered when designing parts for CNC machines if maximum accuracy is expected without manual intervention afterward.

Despite these drawbacks, CNC machining remains one of the most popular manufacturing methods today thanks largely due its ability not only allow mass production but also customized designs at reasonable costs & rapid turnaround times, which makes it highly attractive for companies in various sectors that want good quality & reliable components delivered quickly & cost effectively across large volumes or batches of varying sizes!

Given all this information about what CNC machining involves – Is it a good career choice? Absolutely – although experience & knowledge of CAD/ CAM software may help too to get ahead – because demand for skilled professionals in this field continues to remain high & salaries tend to rise accordingly depending on experience level!

Furthermore, those interested should remember that opportunities exist everywhere, from small local workshops to mid-sized companies to international corporations – giving plenty of scopes when deciding where to invest their future professional development!

The education and training required to be a CNC machinist

If you’re looking for a career in manufacturing, becoming a CNC machinist could be a good fit. CNC stands for computer numerical control, the technology used to control machine tools through computer programming. This type of machining is used to create parts from raw materials such as metals and plastics. It is highly precise and can create complex shapes and designs with repeatable accuracy. But before becoming a CNC machinist, you’ll need to complete certain education and training requirements.

The first step towards becoming a CNC machinist is to obtain an associate’s degree or certificate in the field. Most community colleges offer courses related to CNC machining, usually in engineering technology programs or precision production programs. These courses will teach you the fundamentals of how computers control machines and how they are programmed and operated. You’ll also learn about the materials typically used in this type of work and safety considerations when working with these materials.

In addition to classroom instruction, hands-on experience is also important for prospective CNC machinists. Many schools offer internships where students can gain real-world experience at different companies in their local areas. If an internship isn’t available, consider seeking other opportunities, such as attending job fairs or apprenticeships, to gain further experience before entering into full-time employment as a CNC machinist. This experience will help you develop skills specific to your particular industry and make you more attractive in the job market.

Once you’ve completed your education, it’s time to start looking for employment opportunities as a CNC machinist. You may want to start by searching online job sites such as Indeed or Monster for vacancies occurring near your area. Alternatively, joining professional organizations such as The National Institute of Metalworking Skills (NIMS) could open up networking opportunities that could lead you directly into an open position without requiring further searching!

Is CNC Machining a Good Career? Absolutely! With technological advancements happening all around us daily, there continues to be an increased demand for skilled workers who can operate these machines effectively. Plus, since most companies prefer hiring experienced personnel over newbies, those who have received quality training from accredited programs stand out from the competition. Additionally, depending on your skill level, some states even offer certification programs that can open up doors for higher-paying positions!

The types of jobs a CNC machinist can do.

CNC machining is quickly becoming one of the most sought-after trades in the manufacturing industry, and for a good reason. With a CNC machinist career, you can be sure that you will find steady work with an excellent salary.

CNC machinists have many tasks, from producing parts and components to programming software and performing machine maintenance. This blog post will explore the types of jobs a CNC machinist can do and why it might be a good career choice for those looking to break into the manufacturing industry.

A CNC machine operator is responsible for setting up and maintaining computer-controlled machines used in precision metalworking. The job involves programming the CNC machine to cut metal into components with precise measurement accuracy at high speed. To ensure accuracy, the operator must read engineering drawings and use advanced measuring tools like calipers and micrometers to verify correct dimensions. Machines must also be kept clean and well maintained according to safety protocols or risk causing damage or injury to personnel or equipment.

In addition to machine operation, CNC machinists can also specialize in programming specific tasks within their shop or field. Programmers create code from scratch using various languages such as G-Code or CAM software packages that control how parts are manufactured from start to finish; they also update existing code when new products require different levels of refinement. This requires strong technical skills and knowledge of mathematics and engineering principles so that tolerances are met and customer expectations are achieved.

When deciding if CNC machining is a good career choice, potential applicants should consider both the pros and cons associated with this trade:

On the one hand, there is great job security as demand for qualified technicians remains high due to continued advancements in modern manufacturing technology; plus, wages tend to be higher than average in comparison to other manual labor jobs since operators have specialized knowledge of working with high-end industrial machinery. On the other hand, depending on where you live, there may not be many companies looking for experienced professionals in this field – making it difficult for those just starting; additionally, some employers require workers who can work long hours without any overtime pay involved – which may not appeal to everyone seeking full-time employment opportunities.

In conclusion, although some cons are associated with becoming a CNC machinist, overall, it’s still considered one of the more secure trades available today – offering excellent job security paired with meaningful wages that tend to be higher than average compared to other manual labor positions. Plus, by learning advanced programming skills in addition to machine operation, individuals can further their careers by becoming even more valuable assets within their particular industries – helping them achieve long-term stability and success.

The salary range for CNC machinists

Are you considering a career in CNC Machining? If so, it is important to know the salary range for this profession. It is also important to understand what a job in this field entails and whether it is right for you.

CNC machinists operate computer numerical control (CNC) machines to create precision parts. They are highly trained professionals who generally have a high school diploma and specialized training in machining technology. They use CNC tools such as lathes and mills to create components according to blueprints or other specifications. The job requires a good eye for detail, a steady hand, and excellent problem-solving skills.

The salary range for CNC machinists varies depending on experience level, geographic region, and type of employer. According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for CNC machinists was $39,690 in May 2019, with the lowest 10 percent earning less than $27,400 per year and the highest 10 percent earning more than $62,630 annually. The top-paying industries were aerospace products and parts manufacturing ($51,460 median annual wage), fabricated metal product manufacturing ($44,100 median annual wage), and computer and electronic product manufacturing ($42,880 median annual wage).

When looking at specific geographic regions within the U.S., BLS data shows that Alaska has the highest salary range at $50,170—$81,580 per year, followed by Hawaii at $46,050—$72,840; Connecticut at $45,080—$67 670; Massachusetts at $44 350—$71 170; New Jersey at $43 830—$69 290; and California at $42 040—$68 400 per year. Salaries tend to be higher with larger companies that offer competitive benefits packages such as 401(k) plans or health insurance plans.

In addition to an above-average salary potential compared to other types of jobs in manufacturing industries (such as assembly line workers or welders), there are also several advantages offered by working as a CNC machinery technician: job security due to demand for experienced personnel; opportunities for advancement within the company through additional training; flexible work environments since most shifts are during daytime hours Monday through Friday; and the possibility of overtime pay when needed by employers during peak production times throughout the year.

Is CNC Machining a Good Career? For those interested in entering this field with its solid earning potential combined with extensive job security benefits, then pursuing a career as a CNC Machinery technician may prove advantageous over other careers paths requiring similar levels of technical skill sets but without these same rewards being offered financially or personally within their career path trajectory opportunities.

Pros and cons of a career in CNC machining

A career in CNC machining has become increasingly popular in recent years as computer numerical control (CNC) machines have become more affordable and accessible. CNC machining offers a variety of advantages for those looking to pursue a career in the field, from job security to high salaries. Still, like any profession, it comes with its own set of drawbacks that potential CNC Machinists should consider before pursuing. In this post, we’ll be looking at the pros and cons of a career in CNC Machining so you can decide if it’s the right path for you.

The Pros of Pursuing a Career in CNC Machining

1. Job Security – CNC machining is used extensively across multiple industries. This means that there is likely to be a wide range of job opportunities available to those who specialize in this field. This job security level can help provide peace of mind when taking on such a specialized role.

2. High Salaries – Besides providing job security, experienced and skilled enough to take on advanced positions within the field often earn substantial salaries due to their expertise and experience within the industry.

3. Variety – Much like other manufacturing jobs, CNC machinists will often work on different projects daily, which can help keep them interested and engaged with their work by regularly providing new challenges.

4. Marketable Skills – As technology advances rapidly within manufacturing processes, skills related to these advanced techniques have become highly marketable in an ever-growing range of sectors outside traditional manufacturing roles, such as automotive or aerospace engineering.

The Cons of Pursuing a Career in CNC Machining

1. Potential for Injury – Working with heavy machinery is always dangerous; therefore, anyone considering a career in CNC machining should understand the risks associated with operating these types of machines and must exercise caution while doing so. It can also be physically demanding work, so those with existing injuries or medical conditions may not want to choose this route as a career option due to the potential for further complications due to overuse or strain injuries associated with manual labor involved in operating these machines safely and efficiently over long periods.

2. Initial Investment Costs – To get started within this sector requires considerable investment both financially as well as technically; Most entry-level positions require operators who possess sufficient knowledge on how best to utilize computer-aided design (CAD) software which requires training before attempting any practical implementations alongside various certifications which may need renewing periodically for higher levels positions within certain industries such as aerospace engineering which require very specific qualifications for legal compliance reasons that must be adhered too otherwise employers may face hefty fines from regulatory bodies within their respective industries.

3. Limited Opportunities – While larger organizations tend to focus on hiring people specifically trained up for their respective roles where safety and quality assurance protocols are strictly enforced, smaller organizations often go down routes other than investing in hiring properly qualified personnel where they might overlook important safety regulations when trying to stay competitively priced against larger companies who do invest into having professionally trained staff working on their premises; This could put some people off who would prefer working only within roles where safety procedures were adhered too properly at all times potentially limiting available opportunities depending on location and industry sector being considered.

Overall, it’s up to each person’s unique circumstances whether they feel pursuing a career in CNC machining is suitable. Each person needs to assess their situation carefully before making any financial commitments towards training or education courses required before getting started professionally.

On the one hand, there before positives associated with taking up such a position, including job security, high salaries, variety, and skill set transferability amongst multiple sectors; However, there are some dangers commonly associated when working with heavy machinery; initial investment costs may also prove prohibitive along limited opportunities depending on certain areas.

How to become a CNC machinist

Are you considering a career in CNC machining? If so, you’ve come to the right place. CNC machining is incredibly rewarding, with plenty of potential for growth and advancement. It requires dedication, skill, and precision – all of which can be cultivated through practice and experience. In this blog post, we’ll discuss what it takes to become a successful CNC machinist and why it could be your career choice.

To start, let’s define what CNC machining is. CNC stands for Computer Numerical Control and is a process through which machines are programmed to create parts with precise dimensions or specifications automatically. This process is used in various industries, including aerospace, automotive, and medical device manufacturing. The job of a CNC machinist is to program these machines according to customer needs, ensuring accuracy and quality control throughout the production process.

The first step to becoming a CNC machinist is obtaining the necessary education or training to understand how these machines work. Many schools offer certifications or degrees focusing on machine tool operation; however, many employers also prefer candidates with some technical knowledge or experience working with tools like lathes or mills.

Additionally, apprenticeships provide hands-on learning opportunities from experienced professionals in the field. Aspiring CNC machinists must understand basic mathematics and geometry to properly program and operate these machines since they rely heavily on calculations like angles, depths, lengths, etc., while making precise cuts into materials like metal or plastic.

Is CNC Machining A Good Career? Yes absolutely! Not only does it provide stable employment with competitive wages, but there are also many opportunities for advancement within the industry since it continues to advance rapidly due to increasing demand from various sectors such as aerospace and automotive.

This means there is always room for growth in your CNC machinist career due to its consistently high demand across multiple industries worldwide. Furthermore, because of its computer-aided nature combined with its automated process capabilities, there are fewer risks associated with this type of job than other manual labor jobs requiring intensive physical labor over long periods (i.e., welding).

CNC machinists must also possess excellent problem-solving skills coupled with good attention to detail to maintain accurate records throughout their worksite processes as well as troubleshoot any errors that may arise during operation overnight shifts may also be required depending on where someone is employed; however, overtime compensation usually makes up for any inconvenience caused by late hours spent at work! Lastly, communication skills are also essential as communication between team members ensures that all operations run smoothly both internally between employees/managers/etc., as well externally between customers/suppliers/etc。

In conclusion, if you’re looking for a rewarding career path that offers stability and plenty of room for growth, look no further than becoming a successful CNC Machinist! With just the right combination of technical knowledge & skill sets coupled with problem-solving abilities & attention to detail – anyone can become adept at utilizing pre-programmed tools & equipment necessary for precision part production in today’s modern world!