[lwptoc]

What is a CNC machine, and what does it do

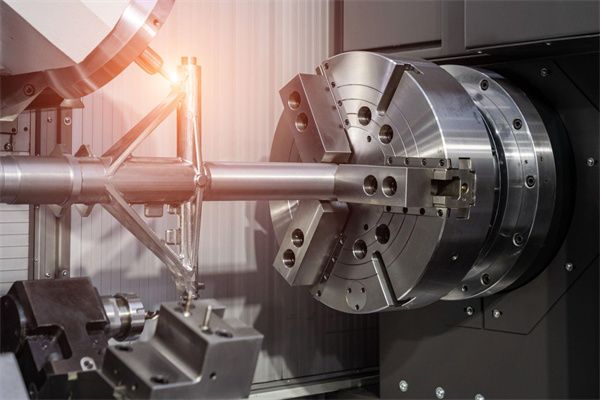

A CNC machine is a computer-controlled device that can automate any industrial process, including machining and cutting metals. Computer Numerical Control (CNC) machines are highly precise and accurate pieces of machinery capable of cutting, shaping, and drilling into materials with intricate precision. When it comes to metalworking, CNC machines have become an invaluable tool in manufacturing due to their ability to machine complex parts quickly and accurately. But just how versatile are these machines? Can a CNC machine cut metal?

The answer to this question is a resounding yes! CNC machines are indeed capable of cutting any metal. CNCs can accurately cut the stock into whatever shape or size you req, f, ire, from aluminum and stainless steel to copper and titanium alloys. The process begins by placing the raw material onto the bed or table of the CNC machine—this could be sheet stock, tube stock, or pre-shaped pieces. Once loaded onto the table, you’ll want to ensure that it has been properly aligned so as not to cause any damage during the machining process.

From there, you’ll want to program your CNC machine with a CAM (Computer Aided Machining) software package to create a code that will direct the head on how to move to achieve your desired results. This code will tell the head what type of tool needs to be used at each stage (spindle speed, feed rate), where it should move along its three axes X/Y/Z, and which direction it should run in – clockwise or counterclockwise. Once completed and checked over for accuracy by a technician, you’re ready for cutting!

Depending on your setup, this could be done manually using manual tool changeovers (MTC) or automatically using Automatic Tool Changeover (ATC). Manually changing tools allow for more control over each part while also reducing downtime between parts – perfect for those looking for faster production times, whereas automatic tool changeover allows for larger batches of parts with minimal operator intervention needed – great for those looking for large-scale production runs. Whatever approach you choose, however, one thing remains certain: with a modern-day CNC machine, you can cut most metals quickly and accurately with almost no margin for error!

In conclusion, when operated correctly by an experienced professional who knows exactly how their chosen machine works, a modern-day CNC machine can cut any metal quickly and precisely according to your specifications – making them an invaluable part of many industrial processes today!

How is a CNC machine different from other machines?

When considering the process of machining, one of the most important tools that a shop has at its disposal is a computer numerical control (CNC) machine. CNC machines are automated, programmable machines that can cut, mill, and shape metals and other materials into various shapes and sizes. They are used in many industries, from automotive and aerospace to medical device manufacturing and home hobbyist projects. While CNC machines have many similarities to traditional manual machining tools, some notable differences make them stand out.

One of the most significant differences between CNC machines and traditional manual machining tools is their level of precision. CNC machines are designed to produce parts with consistent uniformity, while manual machining tools require highly skilled operators to produce accurate results. This ensures that each part produced by a CNC machine will be the same as the last, making it an invaluable tool in mass production processes.

Another major difference between these two types of machining lies in the speed at which they operate. Traditional manual machining is typically slower than CNC due to its reliance on operator input for every process step. With a CNC machine, however, all steps can be programmed ahead of time so that once initiated, the machine can run at optimal speeds without needing additional human intervention or guidance. This allows for faster production times with fewer mistakes made along the way.

Finally, when it comes to cutting metal with either type of machine, there is a significant difference in their capabilities. Manual cutting tools require specialized operators. CNC machines offer precise control over depth and angle adjustments, allowing users to achieve high-quality results quickly and accurately regardless of material type or thickness. Additionally, because all parameters can be easily programmed ahead of time, users will have no issues adjusting their settings as needed for any changes required during production runs.

In conclusion, there are many differences between CNC machines and traditional manual machining tools regarding precision levels achieved during production runs, speed of operation, and ability to cut metal accurately and quickly. Using a modern CNC machine gives users access to higher levels of automation with improved accuracy rates compared to what could be achieved manually – making them an invaluable asset for any shop looking for reliable results from their projects every time!

What materials can a CNC machine cut?

Computer numerical control (CNC) machines are versatile tools that can cut and shape various materials. CNC machines are widely used to cut metals, wood, plastics, and other materials. So, what materials can a CNC machine cut?

When it comes to metal, CNC machines can cut aluminum, brass, copper, steel alloys, stainless steel, and titanium. They can also cut plastics such as acrylics, polycarbonates, and non-metallic materials like wood and foam.

CNC machines use a computer to control the movement of the cutting tool. The computer directs the cutting tool along predetermined paths at specific speeds and depths to create the desired shapes or features in the machined material. This process is highly precise since the cutting path is programmed into the computer before machining begins. With modern CNC machinery, complicated contours and geometries can be quickly produced with great accuracy.

The type of material that you will use with your CNC machine depends on the specific application you have in mind. For example, if you plan on making furniture out of wood or plastic parts out of plastic, then a CNC router will likely be your best bet since it has tools specifically designed for those applications. On the other hand, if you want to machine metal parts, you would need a different type of CNC machine, such as a milling machine or lathe, which has appropriate tools for machining metals more effectively.

As far as safety is concerned when dealing with metals and other hard materials, operators must take proper precautions when working with CNC machinery by wearing appropriate PPE (Personal Protective Equipment) while operating these machines to protect themselves from potential hazards such as debris flying off during operation due to high speeds or sharp edges created by machining processes.

Additionally, it is recommended that operators learn how to properly set up their CNC machines according to manufacturer instructions before running operations to minimize any risk posed by improper setup, which could lead to damage both on the machinery itself or surrounding objects/people due sharp edges from previously cut pieces, etc.

To sum up, a CNC machine can be used for cutting various materials such as metals (aluminum, brass, copper, etc.), woods (hardwoods, softwoods, plywood, MDF, etc.), plastics (acrylics, polycarbonates, etc.), and non-metallic materials like foam, rubber, cork, leather, etc. However, operators must select an appropriate tooling setup according to the material they intend to cut to ensure the best results while taking proper safety precautions to protect them from any potential hazards associated with operating these machines.

What are the benefits of using a CNC machine to cut metal?

A CNC machine is a computer-controlled device that cuts and shapes materials like metal, wood, plastics, and composites. CNC machines are an invaluable tool in the manufacturing industry; they allow for precise cuts with minimal waste and high production efficiency. CNC machines offer many advantages over traditional cutting techniques in the metalworking sector.

The most significant benefit of using a CNC machine to cut metal is accuracy. When operated properly, these machines can produce virtual replicas identical to their CAD design model. Traditional cutting techniques–such as stamping or sawing–can be prone to errors due to human error or inconsistencies in material properties that can lead to faulty parts. A CNC machine removes these potential sources of error by executing commands precisely and consistently with each cut. This means that parts are more consistent in size, shape, and finish quality than had been produced manually.

In addition to its accuracy benefits, using a CNC machine for metal fabrication also offers cost savings compared to manual methods. These machines can completely automate the cutting process, significantly reducing labor costs and increasing productivity. Furthermore, since it produces minimal scrap material due to its accuracy and precision, it can also help reduce waste costs associated with traditional manufacturing methods.

Finally, many modern CNC machines come with software packages that make programming easy and quick for novice operators. This eliminates the need for expensive programming specialists or machinists who may not always be available when needed – saving businesses time and money in the long run.

Overall, there are numerous benefits to using a CNC machine for cutting metal instead of traditional cutting methods. It provides greater accuracy and offers faster operation times and cost savings over manual processes while eliminating potential sources of human error, such as inconsistency in part sizes or shapes from operator fatigue or lack of experience with specific materials or tools. Thus if you’re looking for ways to save time and money while maximizing efficiency on your next project, then investing in a quality industrial-grade CNC machine may be just what you need!

How much does a CNC machine cost

CNC machines have been an invaluable tool for manufacturing and production businesses since their invention. However, one of the biggest questions people often have before investing in a CNC machine is, “How much does a CNC machine cost?” Before answering this question, it’s important to understand CNC machines and what they can do.

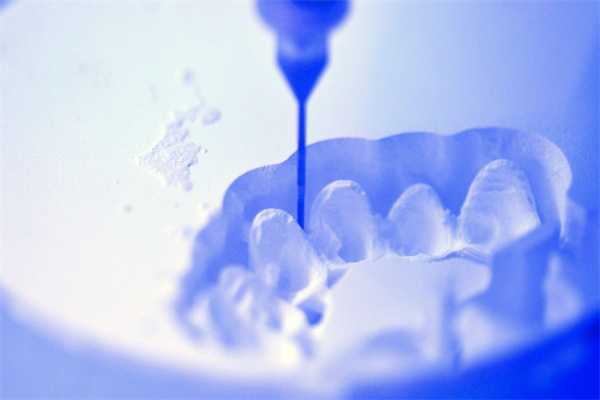

A CNC (Computer Numerical Control) machine is an automated metalworking system that uses computerized instructions to control various aspects of the manufacturing process. The instructions sent to the machine allow for precision cutting and drilling of metal components and other materials such as wood, plastic, and composite materials. CNC machines are used in many industries, including automotive, aerospace, and medical device manufacturing; they’re also used in 3D printing applications and prototyping processes.

When looking at the cost of a CNC machine, there are several factors to keep in mind. First, the type of material being cut plays a role in determining the cost of a CNC machine because different materials require different speeds or feed for optimal results. Additionally, each type of material has its specific requirements for cutting tools which adds to the overall cost of a CNC machine. Additionally, more complex projects may require specialized tools, increasing costs.

The size and complexity of the project also affect how much a CNC machine costs – larger projects will require more powerful machines with higher accuracy rates. In comparison, smaller projects may be able to use less expensive models with lower accuracy rates. Other factors that affect the cost include brand name recognition, years on the market selling similar machines, and after-sales support services offered by manufacturers or distributors.

Finally, when considering whether your business needs a CNC machine, one important thing to consider is whether or not it can cut metal specifically – Can a CNC Machine Cut Metal? The answer is yes – with proper setup. Any material can be cut using an industrial-grade CNC router or milling system, including metals like aluminum, steel, and titanium alloys and other materials such as wood composites and plastics. With proper programming, these machines can create complex parts with intricate details that would otherwise be impossible without manual labor or specialized equipment like grinding wheels or manual cutting tools.

In conclusion, when looking at how much a CNC machine costs, it depends on many factors, including the type of material being cut/drilled/machined, size/complexity of the project being worked on, as well as brand reputation/after-sale services offered by the manufacturer/distributor. Still, they can cut metal specifically when properly set up and programmed with great precision. Accuracy levels regardless of project size or complexity level desired outcome require.

Who should use a CNC machine to cut metal

CNC (Computer Numerical Control) machines are versatile and highly accurate tools used to cut metal precisely in industrial settings. CNC machines can be used by professionals and hobbyists alike, allowing for a wide range of applications from small-scale prototyping to large-scale production. So who should use a CNC machine to cut metal? Let’s look at the advantages of using a CNC machine and some of its applications.

The main advantage of using a CNC machine to cut metal is its accuracy and level of detail. A CNC machine is designed to follow precise instructions, meaning it can produce an intricate design with exact measurements down to the micron. A CNC machine can also save time when producing multiple parts, as the same instructions can be repeated repeatedly without making adjustments or reworking mistakes. This makes it an ideal choice for mass production and prototyping projects.

In terms of application, many industries use CNC machines for automotive. Manufacturing plants commonly use this technology to create car parts such as wheel hubs or exhaust systems. In contrast, aerospace engineers use them to produce aircraft components like engine cases or landing gear components. On top of this, there are many smaller-scale uses, including creating jewelry pieces, engraving trophies or awards, or prototyping architectural designs.

Due to its versatility, the CNC machine has become increasingly popular with hobbyists looking for an affordable way to get started with machining metals at home. While these machines require some knowledge and experience on how to operate them safely and effectively, advances in automation have made them more user-friendly than ever before. With some basic training and practice, anyone can learn how to set up and run their parts on a home workshop CNC mill or router.

Overall, it’s clear that the answer to “Can a CNC Machine Cut Metal” is yes! While professional technicians may be familiar with operating these machines for mass production purposes, affordable home workshop solutions have opened up incredible possibilities for hobbyists and DIY enthusiasts looking for an efficient way to prototype projects at home without sacrificing accurate results.