[lwptoc]

What is a CNC machine, and what can it do for your business

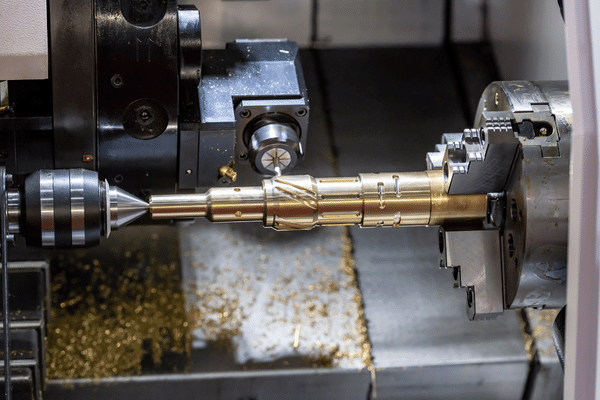

A CNC machine (Computer Numerical Control) is an automated piece of engineering equipment that can fabricate parts with high accuracy and precision. CNC machines often create components for various products, including automobiles, electronics, furniture, etc. CNC machines have become increasingly popular over the past few decades as manufacturers realize the benefits of this technology.

For businesses looking to streamline their production processes and increase efficiency, CNC machines offer several advantages. By automating the fabrication process with a computer-controlled system, businesses can save time and money while improving product quality. Additionally, CNC machines allow for increased flexibility in producing different parts. Businesses can quickly adapt their production strategy to meet changing customer needs without purchasing new machinery or hiring additional personnel.

The first step in using a CNC machine is programming it so that it can accurately fabricate components according to plans provided by the manufacturer. This process often involves CAD/CAM software and requires specialized knowledge to operate the machinery properly. Once programmed correctly. However, the machine can produce parts to the specifications provided by its users.

Another major benefit of using a CNC machine is its ability to reduce waste during production processes by ensuring accuracy and precision with each component. Since all parts are fabricated according to detailed plans, errors are less likely to occur, which helps eliminate wasteful materials used in production processes. Additionally, because all components produced have a high degree of accuracy and consistency, assembly times usually decrease significantly when utilizing a CNC machine compared to traditional manual methods.

The final benefit of using a CNC machine is its cost-effectiveness compared to traditional machinery or labor-intensive fabrication methods. By reducing overhead costs associated with extra personnel or inefficient machinery operations, businesses can keep their prices competitive while still producing quality products at scale. Additionally, since these machines require minimal maintenance compared to other manufacturing tools, they can provide long-term savings for any business looking to cut costs without sacrificing quality standards.

In conclusion, incorporating a CNC machine into your business can provide numerous advantages that help improve productivity and lower overhead costs associated with traditional manufacturing methods. From increased accuracy and precision during fabrication processes to reduced waste material due to fewer errors occurring – investing in this technology could be highly beneficial for any business looking for ways to maximize their efficiency while still providing superior product quality at competitive prices

The cost of a CNC machine and how to make the most of your investment

The CNC (Computer Numerical Control) machine has become an increasingly popular tool in modern manufacturing. It is an automated machine that can produce components with precision and accuracy. While these machines come with a hefty price tag, they are worth the investment if you want increased productivity and efficiency. This blog post will look at the cost of a CNC machine and how you can make the most out of your investment.

Cost of a CNC Machine

One of the biggest considerations anyone should make before purchasing a CNC machine is the cost. The price tag on these machines varies depending on the type and features included, but generally, they start at around USD 10,000. High-end models can range up to $100,000 or more. To calculate a more accurate estimate for your particular project needs, you should consider factors such as the size and complexity of parts machined, desired speed and accuracy, available space for operation, and setup time required for programming changes.

Increasing Productivity & Efficiency with Your Investment

Once you have factored in all associated costs and determined which type of CNC machine suits your needs, it’s time to consider maximizing your investment by increasing productivity and efficiency. Here are some tips to help you do just that:

• Utilize CAD/CAM software – Designing parts using Computer-Aided Design (CAD) software helps reduce errors during manufacturing, as most programs detect potential issues before production. Additionally, CAM software can generate G-code (the language used by CNC machines) quickly to minimize setup time between projects – resulting in higher efficiency overall.

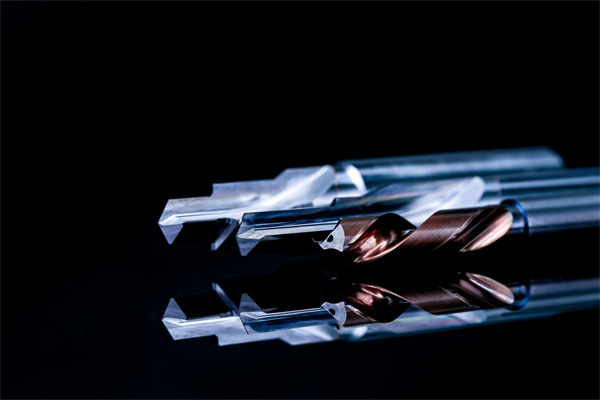

• Invest in Quality Tools – It is important not to skimp on tools when setting up your CNC machine since quality tools will last longer, which means fewer replacement costs over time. Additionally, well-made tools provide better surface finishes, improving product quality and aesthetics while avoiding costly repairs down the road due to damaged components from inferior cutting tools.

• Automate Where Possible – Many processes that involve manual labor can be automated with custom programming making it easier to manage large projects with tight deadlines without compromising on quality or accuracy due to human error or fatigue. Although this may require an initial investment in programming resources upfront, it will eventually lead to higher profits down the line due to increased efficiency from automation capabilities within your shop environment.

Overall, investing in a CNC machine is worth it if you understand what you need from it and then put strategies that enable you to maximize its potential by increasing productivity and efficiency within your shop environment. Although these machines come at high prices initially, their long-term value far outweighs their cost as they allow businesses to scale up quickly while reducing overhead costs due to their ability to automate processes that were traditionally performed manually.

Pros and cons of owning a CNC machine

Are you considering investing in a CNC machine for your business? CNC (Computer Numerical Control) machines are cutting-edge technologies that can help increase efficiency and accuracy in the manufacturing process. While there are numerous advantages to owning a CNC machine, there are also some downsides. In this blog post, we will discuss the pros and cons of owning a CNC machine so that you can determine if it’s worth the investment for your business.

Pros of Owning a CNC Machine

1. Increased Efficiency:

One of the biggest advantages of using a CNC machine is that it can significantly improve production speeds and reduce labor costs. A CNC machine cant faster speeds than human hands, capping more parts can be produced in less time. This not only increases output but reduces costs associated with labor as well.

2. Improved Precision:

Another advantage of using a CNC machine is its increased precision compared to manual machinery or tools. These machines can maintain consistent accuracy during the production process due to their use of computer-controlled commands instead of human operators. This means that parts produced with a CNC machine will be more precise and uniform than those made by hand, leading to improved quality control throughout the manufacturing process.

3. Reduced Material Waste:

Another benefit of owning a CNC machine is its ability to reduce waste when creating parts or products from raw materials. Since these machines have precise control over their movements, they can use all the material provided, reducing scrap loss and saving money on resources used in production processes.

Cons of Owning a CNC Machine

1. Initial Investment Cost:

One downside of purchasing a CNC machine is the initial cost involved with such an investment; these machines can be quite expensive depending on the model you choose and its capabilities. For many businesses, this high upfront cost may be too much for them to bear without seeing significant returns on their investments right away– something that may not happen until months or even years down the line when production has increased enough due to improved efficiency from the new equipment.

2 . Maintenance Costs:

Another disadvantage associated with owning a CNC machine is the need for regular maintenance; these machines require frequent calibrations and repairs to stay running properly, which can be quite costly over time if not taken care of properly by knowledgeable technicians or operators familiar with such machinery. Additionally, due to their complex nature, additional costs may be associated with training personnel who need to operate or repair these machines and any software needed for programming them correctly before use on production lines.

3 . Complicated Programming Processes:

Lastly, while modern technology has made programming processes easier than they used to be, they still can be quite complex at times which makes troubleshooting difficult without proper knowledge or experience working with such machinery beforehand; this could potentially lead to delays in production due to problems arising from poor coding practices unless employees are adequately trained beforehand how to correctly program these machines before use on actual projects or tasks requiring their services too often leading further delays in completing projects on schedule.

Conclusion :

Ultimately whether investing in purchasing one or several computer numerical control (CNC) machines is worth it depends largely upon your individual business needs as well as budget constraints amongst other factors like space available etc.; however, based on everything discussed above, one should also take into account both long term maintenance costs along with an experienced workforce whose knowledge regarding both hardware and software components being used will help ensure maximum productivity levels remain consistent throughout operations while mitigating any potential risks that may arise unexpectedly.

How to choose the right CNC machine for your needs

Choosing the right CNC (Computer Numerical Control) machine for your needs can be difficult and overwhelming. However, it is of great importance to select a machine that will best suit the needs of your particular job or project. Before selecting the most suitable CNC machine for you, it is essential to consider all factors, such as budget, space availability, accuracy and repeatability requirements, operation speed, and use complexity.

For starters, it is important to identify what kind of CNC machine will suit your specific needs. Each type has its benefits and drawbacks, which must be considered when making an informed decision. For example, while 3-axis machines are more affordable than 5-axis models, they are limited in the types of projects they can handle. On the other hand, 5-axis machines provide greater versatility but come at a higher price tag. Once you have decided on the type of CNC machine that fits your project requirements best, you should look into its capabilities, how fast it can run operations, and how accurately it can execute them.

When selecting one for your needs, it is also critical to consider the cost associated with operating a CNC machine. Purchasing a new or used CNC machine depends on many factors, including size and features; however, operational costs should never be overlooked as they could significantly affect your long-term returns from using this machinery. Operational costs include maintenance (such as replacing broken parts), energy consumption (electricity bills), labor costs (if any), and software licenses (if applicable).

Finally, various user interfaces are available for controlling CNC machines, depending on their capabilities and features. Some modern machines come with graphical LCD screens where commands can be input directly without needing any programming knowledge; these tend to be more user-friendly than traditional numerical control systems, which require users to enter commands through keypad-style input devices such as punch tapes or teletype keyboards. It is important to understand the complexities associated with each interface before selecting one since this may affect how quickly you learn how to operate it effectively.

Choosing the right CNC machine for your needs requires careful consideration of several factors, including budget constraints, space availability, accuracy/repeatability requirements, speed of operation required, the complexity of use, desired, and cost associated with operation. After considering these elements, you will be better equipped to make an informed decision about which CNC machine best fits your specific project requirements and budgetary restrictions—ultimately helping ensure that you get maximum value out of investing in such equipment in both short-term and long-term scenarios.

When considering whether or not investing in a CNC machine is worth it for you specifically, it goes without saying that different jobs have different needs & budgets. Hence, there isn’t a one size fits all answer here – however, if you have identified that certain tasks would be greatly improved by having access to precision machinery, then absolutely – investing in a CNC could open up new possibilities & increase output & efficiency significantly over time – Depending on your industry & application there are also many options available so make sure to research the market thoroughly before committing – When done correctly & within budget constraints investing in a good quality piece of machinery like this can pay off big time!

Tips for using a CNC machine in your business

A CNC machine can be an invaluable tool for businesses that need to produce high-quality parts quickly and accurately. Computer numerical control (CNC) machines use computer-controlled programs to cut, shape, and shape materials into specific shapes with high precision. This blog post will explore the benefits of using a CNC machine in your business operations and provide tips for getting the most out of your investment.

Many advantages come with investing in a CNC machine for your business. Automating the production process can increase productivity and accuracy while reducing operator fatigue and material waste. Additionally, when properly programmed, a CNC machine can produce identical components with consistent tolerances regardless of the size or complexity of the part. This means you will always have quality parts on hand whenever needed.

When deciding if a CNC machine is worth it for your business operations, there are a few important factors to consider. First and foremost, consider the costs associated with acquiring and operating one in comparison to other methods of manufacturing parts. If you plan on using it regularly, investing in one may be more cost-effective than paying someone else to manufacture parts on your behalf. It’s also important to remember that while initial startup costs can be high due to purchasing equipment and programming software, long-term savings can be realized through increased productivity and greater efficiency.

Once you’ve decided that investing in a CNC machine is right for your business operations, there are several steps you can take to ensure its success:

1. Invest in quality equipment:

You want reliable machinery that does not break down frequently or requires excessive maintenance downtime. Look for reputable suppliers offering warranties on their products, so you know they stand by their products.

2. Purchase compatible tools:

Ensure all of the tools used within your setup are compatible before making any purchases; otherwise, costly mistakes could occur when attempting operation or setting up procedures later on down the line.

3. Research manufacturers:

Take some time to research different manufacturers to decide which offers the best value and features for your needs. Consider compatibility with other machines and customer service ratings before committing to any particular model or brand-name product.

4 Train operators:

Proper training is essential when operating any machinery; errors made during operation can result in wasted materials and costly repairs down the line, so having adequately trained personnel is essential for successful operation. Additionally, certifications may also be required depending on what specific tasks the machine is being utilized for.

5 Maintain safety protocols :

Safety should always come first when dealing with heavy machinery like CNC machines; proper safety protocols help keep workers safe by minimizing potential risks associated with working around complex machinery. Regularly scheduled maintenance checks should also be conducted to ensure optimum performance.

In conclusion, investing in a CNC machine has numerous benefits – increased accuracy, consistency, reduced material waste, and operator fatigue – but it’s important to consider all aspects before taking the plunge. Ensure considerations such as cost, quality equipment, compatibility, training operators, and maintaining safety protocols have been considered before purchase. With careful consideration up front, you’ll find yourself reaping the rewards from y our investment far into the future!