[lwptoc]

What is a 5-axis CNC machine, and what can it be used for

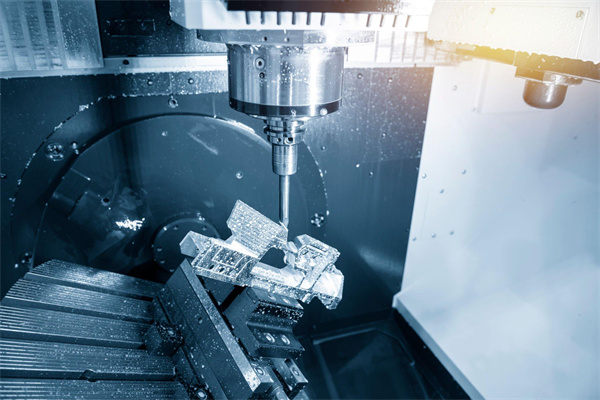

A 5-Axis CNC (Computer Numerical Control) machine is a machine tool that uses computer numerical control programming to move the five axes of a machine simultaneously. This allows for high accuracy and repeatability during machining operations, as well as allowing for complex 3D contouring. 5-axis CNC machines are used in the manufacturing industry for precision cutting, milling, drilling, and turning of metals and plastics into components that meet exact specifications.

5-axis CNC machines have become increasingly popular among manufacturers due to their ability to produce more complex parts in less time than with traditional machining methods. This reduction in processing time also translates into cost savings, which makes 5-axis CNC machines an attractive option for many production facilities. In addition to increased speed and efficiency, 5-axis CNC machines offer improved accuracy and surface finish compared to other metalworking machining processes.

The most common uses of 5-axis CNC machines are in the automotive and aerospace industries; They create components such as engine blocks, cylinder heads, pistons, gears, turbine blades, and other intricate parts requiring high precision tolerances. They can also be used in the medical industry to create implants or prosthetics with tight tolerances for fitment purposes. Other sectors, such as jewelry making, benefit from using 5-axis CNC machines because they allow for intricate designs with complex geometries that would otherwise be impossible or difficult to achieve by hand.

Now that you know what a 5-axis CNC machine is and what it can be used for, you may wonder how much these machines cost. The cost of a 5-axis CNC machine depends on several factors, including the size of the device itself (larger models typically cost more), the type of materials being used (i.e., aluminum vs. steel), the complexity of the parts being produced (more complex parts may require additional features) and finally any other software needed specific to your application (such as CAM software). On average, you can expect prices starting at around USD 25k up to several hundred thousand, depending on your needs.

Overall, investing in a 5-axis CNC machine provides manufacturers with increased accuracy, repeatability, efficiency, and cost savings, making them an attractive option in many industries today. Furthermore, advances in computer numerical control programming mean more excellent capabilities within these machines – including higher speed processes – further pushing their potential than before!

How much do they cost and where can you buy them

5-axis CNC (computer numerical control) machines are the gold standard for machining precision industrial parts. Though these machines can be expensive, they offer unparalleled accuracy and repeatability, enabling the production of high-quality components in a fraction of the time it would take with manual machining processes. This makes them an ideal choice for companies that need to produce intricate details quickly and cost-effectively. But how much does a 5-axis CNC machine cost?

The exact price of a 5-axis CNC machine will depend on its complexity, size, and features. Basic models may start around $30,000, while advanced models can reach hundreds of thousands of dollars. It’s also important to consider the cost of additional tools or software to operate your machine effectively. Generally speaking, though, the more you spend on a higher-end model upfront, the more you’ll save on time and labor costs.

No matter what type of 5-axis CNC machine you’re looking for, you can buy one in plenty of places. Online retailers like Amazon offer various new and used 5-axis machines at different prices. Alternatively, you can buy directly from manufacturers like Haas Automation or Mazak Corporation – two leading innovators in CNC manufacturing technology – who will likely have access to top-of-the-line models that aren’t available anywhere else. Local machine shops may also carry various types of CNC machines; however, their selection may be limited depending on their customer base and inventory availability.

Finally, sites like eBay are worth checking out if you’re looking for a great deal on a used 5-axis CNC machine or other related equipment such as routers or lathes. Here you’ll find listings from private sellers and dealers specializing in buying and selling used industrial equipment at bargain prices – perfect for those who want to get started without breaking the bank!

In conclusion, finding a good deal on a quality 5-axis CNC machine doesn’t have to be difficult if you know where to look. With so many options available online and off – from budget-friendly second-hand models to cutting-edge new machines – there’s sure to be something out there that fits your needs perfectly without breaking the bank. So don’t wait any longer: start shopping around today for the perfect 5-axis CNC machine for your business!

The benefits of owning a 5 axis cnc machine

Owning a 5-axis CNC machine can be an extremely beneficial addition to any business, as it provides precise and accurate cutting capabilities that can save time and money. With its ability to accurately produce complex parts from various materials such as plastics, metals, and composites, the 5-axis CNC machine is often the preferred choice for industrial production operations. But how much does a 5-axis CNC machine cost?

The price range of a 5-axis CNC machine can vary greatly depending on factors like size and features. Generally, you can expect to spend anywhere from $15,000 to over $500,000 for a top-of-the-line model. However, if you are looking for more budget-friendly options, plenty of lower-cost models are available that can still provide an acceptable level of performance. In addition to the machine’s base price, additional costs may include shipping charges, installation fees, and training expenses.

Aside from being more costly than traditional 3-axis machines due to their increased complexity and power requirements, the benefits of owning a 5-axis CNC machine far outweigh their costs. One significant benefit is their ability to produce complex shapes in one setup, which is especially useful for making difficult parts with tight tolerances quickly and accurately. This saves time and money compared to traditional machining processes because fewer setups are required per part, thus leading to increased productivity and reduced waste material.

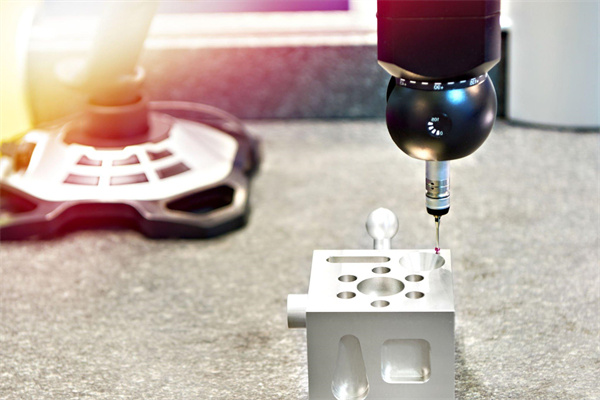

Another advantage is that these machines have excellent repeatability capabilities thanks to their advanced control systems, which allow them to consistently produce high-quality components every time they are used – making them ideal for mass production scenarios or operations requiring high-precision members over; they also offer users greater flexibility in terms of programming capabilities allowing users to create more intricate designs even when working with complex materials such as ceramic or glass composites. Finally, they also offer excellent surface finish results since all axes move simultaneously. They provide smoother cuts than traditional 3-axis machines, which only move two axes simultaneously, resulting in rougher surface finishes requiring further post-processing.

In conclusion, investing in a 5-axis CNC machine is not cheap. Still, it could pay off significantly in terms of efficiency gains over time due to its precision cutting capabilities coupled with its flexibility in terms of programming capabilities and ability to work with complex materials such as ceramic or glass composites. Therefore it’s essential for businesses considering acquiring one to weigh up their options before investing to ensure they get the best value for their money – particularly if mass production or high-precision components are needed regularly.

Things to consider before purchasing a 5 axis cnc machine

You’ve come to the right place if you’re in the market for a 5 Axis CNC Machine. Many factors should be considered when purchasing any device – and a 5 Axis CNC Machine is no different. This blog post will examine some of the critical considerations you should make before buying a 5 Axis CNC Machine.

The first thing to consider is cost. How much does a 5 Axis CNC Machine cost? The short answer is that it will depend on what type of machine you need and its features. Generally speaking, these machines range from around $15,000 up to several hundred thousand dollars depending on the size and capabilities of the device. You’ll also want to factor in additional costs such as installation fees, maintenance fees, and ongoing software updates or upgrades.

The second thing to consider is how much space you have for your machine. Depending on your project’s size or complexity, you may need more than one 5 Axis CNC Machine, so ensure you have enough room for them before making any purchases. Additionally, if space is limited, you might want to look into different types, such as desktop models, which are much more compact but can still get the job done just as effectively as their larger counterparts.

You’ll also want to consider what materials your machine will be working with. Most 4-axis CNC machines are designed specifically for woodworking projects, while 5-axis machines can handle almost anything, including plastics and metals, with relative ease. If you plan on cutting more complex materials such as aluminum, make sure that your chosen model has been designed for it; otherwise, it may not handle it properly or result in poor quality results overall.

When shopping around for a 5-axis CNC machine, carefully check out its features list. Some models may come with computer numerical control (CNC) capabilities while others do not, so ensure that your chosen model comes with the features and settings required for your application before committing to buy it, even if they are slightly more expensive than other models without those features, they will prove invaluable in the long run and save you money in terms of time spent on programming tasks that would otherwise need manual input instead.

Finally, once all other criteria have been met, make sure to do some research on potential manufacturers before placing an order as well; good customer service is vital when it comes to operating something like a 5-axis CNC machine since any issues can quickly become costly if left unresolved so having access to reliable technical support from knowledgeable personnel can help prevent unnecessary downtime due to problems arising from incorrect manufacturing processes or faulty components being installed during assembly etcetera. With all these things considered when looking at how much a 5-axis CNC machine costs, there should be no surprise when you receive your invoice at checkout!

How to use a 5 axis cnc machine

Are you looking to invest in a 5-axis CNC machine? If so, you’ve come to the right place. CNC machines are essential for any shop that manufactures custom parts or components. With a 5-axis CNC machine, you can create complex parts quickly and accurately, upping your production and increasing your profits. But how do you use a 5-axis CNC machine? This blog post will cover the basics of using one and discuss the costs of investing in one.

First, let’s discuss what makes a CNC (computer numerical control) machine different from a traditional milling or cutting system. A CNC machining center uses computer software to control its movements and process the raw material into finished parts or components. It is similar to other types of automated machinery like 3D printers but designed for higher precision and accuracy. It can also produce parts much faster than manual processes due to its automated movement control system.

Now that we have established what sets CNC machines apart from traditional manufacturing techniques let’s discuss how you use one. The most common type of CNC machine is the 3-axis which moves only along three axes – X, Y, and Z – meaning it can only move up/down, left/right, and forward/backward, respectively. A 5-axis machine adds two axes – A (swivel) and B (tilt) – which allow it to rotate the part being machined around two axes and move up/down, left/right, and forward/backward like a 3-axis machine. This expanded range of motion gives manufacturers more flexibility when making complex parts that require intricate angles or curves that would otherwise be difficult with just 3 axes of action available.

Now that we know how a 5-axis CNC works let’s discuss cost considerations when purchasing one for your business needs. The cost for a 5-axis machine will vary depending on the ‘device’s size and any additional features included, such as automation systems or tool changers that may increase efficiency in certain situations. Generally speaking, though, you should expect to spend anywhere from $50K-$200k for an entry-level model depending on specs and configuration options chosen if purchased new from an authorized dealer with full-service capabilities available nearby for maintenance purposes if needed down the road. Used models could be found at lower prices but lack support should problems arise during operation. Hence, it’s essential to consider all factors before deciding to ensure the best fit within the budget while meeting end goals regarding precision requirements, etc.

In conclusion, buying a 5-axis CNC machining center can be expensive but rewarding when used correctly, given its exact capabilities relative to other alternatives today. Contracts with authorized vendors offer greater security than going the used route, as they typically provide warranties on all their products ensuring high levels of quality assurance backed by years of expertise. Ultimately, each shop must decide what works best based on its unique needs. Keeping How Much Does a 5 Axis CNC Machine Cost in mind always so proper budgeting measures can be taken before purchase, thus preventing costly setup delays down the line caused by unexpected issues beyond initial estimates.