[lwptoc]

What is a CNC machine, and what can it do

A CNC machine is a computer numerical control device that uses computers to control machine tools. In the manufacturing industry, they cut and shape materials such as metal, plastic, wood, and other substances into various products. CNC machines are becoming increasingly popular due to their accuracy and ease of use. So can you make money with a CNC machine? The answer is yes!

CNC machines are used in various industries, including automotive, aerospace, medical device manufacturing, electronics production, and 3D printing. With the proper training and knowledge of operating a CNC machine, you could make money with one in no time. CNC machinists are highly sought-after in the tech industry because of their ability to produce complex components quickly and accurately.

You have several options when it comes to making money with a CNC machine. One option is to become an independent contract machinist. This means you would market your services to businesses requiring parts or materials made using a CNC machine. Alternatively, you could find employment as a machinist in one of the many manufacturing firms that regularly use CNC machines for production jobs. The choice is ultimately yours, depending on what works best for your skillset and experience level.

As well as providing services as an independent contractor or employee in the manufacturing sector, there may also be opportunities available for experienced machinists within engineering outfits or design agencies who often require custom parts or specialized components which only a CNC machine can produce accurately.

No matter which routes you choose when making money with a CNC machine, plenty of opportunities will be available if you have the proper skill set and knowledge of how it all works. As a bonus having experience operating a CNC machine also looks great on your resume, so if you’re considering entering this field, now is the time!

Finally, it’s important to remember that when using any machinery, safety must always come first; make sure that all necessary training has been completed before attempting any work on a CNC machine to help ensure the best possible results without putting yourself at risk of any potential accidents or injury caused by incorrect use or operation of machinery.

The different types of CNC machines on the market

Investing in a CNC machine may be a wise decision if you want to start a business or expand your existing operations. CNC (computer numerical control) machines are automated cutting tools that can be programmed to rapidly and accurately produce precision parts and products. With the correct type of CNC machine, you can make money with various materials, including wood, plastic, metal, foam, and composite materials.

When choosing the suitable CNC machine for your business needs, several types are on the market today. One type is the milling machine which uses rotating cutters to remove material from a workpiece to create complex shapes. Milling machines have multiple axes and can handle horizontal and vertical machining tasks. It’s also possible to utilize end mills, drills, and other cutters with this machine.

Another popular type of CNC machine is the router which utilizes either spinning bits or lasers to cut shapes into any material, from foam to hardwood. Routers come in many sizes, from desktop versions to industrial-sized ones that can cut massive sheets of material quickly and precisely.

A lathe is a standard CNC machine that rotates workpieces against cutting tools to shape them into desired shapes, such as cylinders or cones. Lathes often miss spindles or threads on metal parts, turning wooden furniture into kitchen cabinets or bed posts.

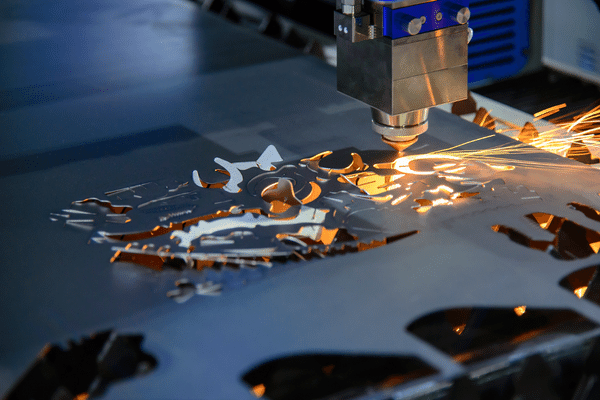

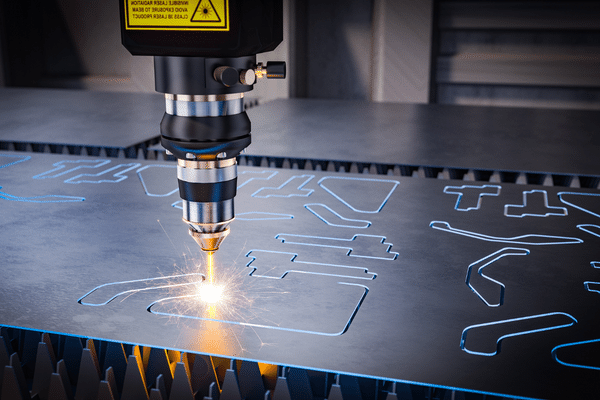

The fourth type of CNC machine is called a plasma cutter which uses an electric arc heated by an inert gas such as argon or helium to cut through conductive metals like steel and aluminum with incredible precision and speed compared to conventional methods such as saws or grinders.

Finally, 3D printers have revolutionized the concept of rapid prototyping by allowing users to print three-dimensional objects quickly and with great detail out of plastic filaments. Many modern 3D printers utilize open-source software like CAD (Computer Aided Design) programs so that users can easily customize their prints before printing them out layer by layer using special heated extruders.

No matter what your needs may be when it comes to producing high-quality parts at cost-adequate speeds, there is sure to be a suitable CNC machine available on the market that fits your budget while providing satisfactory results every time you use it. Investing in one may sound expensive initially, but if done wisely could prove invaluable over time, considering all the money that could be saved on labor costs alone! So if you’re looking for ways of making money quickly, investing in one of these incredible machines might be one option worth exploring further!

How to choose the suitable CNC machine for your needs

Are you looking to buy a CNC machine but unsure which type suits your needs? With so many options available, knowing which is the right choice for you can be difficult. While it may seem overwhelming, there are a few key factors to consider when deciding. In this blog post, we’ll explore how to choose the suitable CNC machine for your needs and if you can make money with a CNC machine.

First, you should consider the type of materials you plan on working with. If you plan on cutting steel or other metals, a milling machine will likely be your best option, as they are specifically designed for metalworking. A router would be more suitable for softer materials such as wood or plastic. You should also consider the size of the parts that need to be machined and whether the CNC machine can handle them. The last factor to consider is your budget; machines are available at all price points depending on your required features and capabilities.

When making money with a CNC machine, many opportunities are available depending on the type and quality of work you produce. As mentioned above, milling machines are optimized for metalworking applications. Hence, these are particularly good for creating custom products and components from metal that have high value in specific industries such as aerospace engineering, automotive manufacturing, and medical device manufacturing. Routers can also be used for more complex projects such as furniture or sculptures, and these tend to fetch higher prices than more basic components produced on milling machines.

Determining how much money you might make with a CNC machine depends mainly on the required work and the industry demand for that particular product or service. Generally speaking, though, it’s possible to generate significant revenues by investing in quality equipment; some users earn thousands per month just from machining jobs alone!

In short, when selecting a CNC machine, it’s important to remember what materials you’ll be working with, the size of parts needed, how much money you’re willing to spend, and if you’re looking at generating income from this venture. With this information in hand, it should make choosing the suitable model easier to improve results faster!

How to set up and use your CNC machine

CNC machines are versatile tools that create various products and parts from wood, metal, plastic, and other materials. They have been around for decades, but in recent years they have become increasingly popular with hobbyists, businesses, and even professionals alike. With their ease of use, accuracy, and ability to produce complex shapes quickly and efficiently, it is easy to see why CNC machines are so popular.

Using a CNC machine requires knowledge of the equipment, its operation, and basic computer skills such as CAD programs or g-code editing software. Setting up a CNC machine can be time-consuming, depending on the complexity of the job at hand. However, with time and effort, you can get your CNC machine up and running quickly with minimum fuss.

The first step when setting up your CNC machine is ensuring all the hardware is installed correctly. All necessary components should be attached securely according to the manufacturer’s instructions before powering up your machine. Additionally, ensuring all moving parts are adequately lubricated before operating your CNC machine is essential.

Once you have completed these steps, you’ll need to set up your software environment – this includes choosing a CAD program or G-Code editor to design or modify your projects with. These programs allow for precise control over the operations that will take place on your CNC machine and should be configured accordingly before use. After completing this step, you’ll need to calibrate your machine. Hence, it understands how it should respond during operations – this ensures that every output is accurate and precise each time you use your CNC machine.

Now that you know how to set up a CNC Machine, it’s time to think about how it can be used for more than just creating objects – Can You Make Money with a CNC Machine? The answer is yes! By utilizing online marketplaces such as Etsy or 3D Hubs, you can list customized pieces created using your own CNC machines for sale – perfect for those looking for unique gifts or personalized items for their home/office/businesses, etc.

You could also offer customization services such as engraving or milling services – perfect if there’s a demand in your local area from small businesses looking for someone who can fulfill orders quickly but accurately without sacrificing quality. Additionally, consider offering contract manufacturing services where companies outsource production tasks that would otherwise tie up resources – freeing them up to focus on other aspects of their business without compromising quality or performance.

Overall, setting up and using a CNC Machine doesn’t have to be daunting once you understand what needs doing and how each component works together as one system! Whether you plan on producing items as gifts or selling them online, there are many opportunities if you’re willing to invest in one!

The benefits of using a CNC machine

A CNC machine can benefit businesses and hobbyists in many ways, making it an invaluable tool. Whether you’re looking to make money with a CNC machine or want to get some projects done more quickly, there are definite advantages to using a CNC machine. Let’s look at the main benefits of using this type of technology.

First, one of the significant benefits of using a CNC machine is that it can help save you time. With computer numerical control (CNC) technology, you can program your machine to perform tasks without manually operating it ay. This means that once the program is set up, you don’t have to keep an eye on it while it runs – freeing up your time for other tasks or activities.

Second, another advantage of using a CNC machine is that it improves accuracy and precision. Since most CNC machines follow instructions precisely as programmed, they produce precise results every time – reducing the number of errors or irregularities in a finished project. This makes them ideal for industries that require highly accurate components, like automotive parts manufacturing and aerospace engineering.

Finally, investing in a CNC machine can be profitable if you use it correctly. You can easily make money from your creations by creating custom parts or products with your designs and then selling them online or through local businesses. Many companies use CNC machines to produce unique pieces, giving them an edge in product variety and quality over competitors who don’t use this technology.

These are just some of the main benefits of using a CNC machine for personal or business purposes. You will save time by programming one project instead of doing everything manually and increase accuracy and precision when producing parts or products – increasing customer satisfaction overall. Plus, if you think strategically about it, there are opportunities to make money with a CNC machine by selling custom designs and components online or through local businesses – giving you another source of income!

The drawbacks of using a CNC machine

If you’re considering adding a CNC machine to your shop, there are some drawbacks. Although they can be exact and efficient, some potential downsides could make them not the best choice for certain operations. In this blog post, we’ll examine some of the potential drawbacks of using a CNC machine, as well as whether or not you can make money with one.

The main issue that comes with a CNC machine is its cost. While it’s true that their cost has gone down considerably over recent years and prices continue to drop, they still require a significant investment in terms of initial outlay. This can be very difficult for smaller operations or those just starting to afford it. Additionally, CNC machines require maintenance and upkeep, which can add to their overall cost over time.

Another downside is that while these machines are exact, they require programming to use them effectively. This means having someone on staff who knows how to write code and operate the software associated with the machines. Without this knowledge, these machines will become expensive paperweights without any practical use in your shop. Additionally, training staff on the operation of the devices can be time-consuming and costly.

Finally, it’s important to note that while CNC machines are incredibly accurate when programmed correctly, mistakes made during programming or setup can lead to significant problems down the line when producing parts for customers. The cost of these mistakes regarding scrap material produced and customer dissatisfaction should also be considered when weighing the pros and cons of buying a CNC machine for your shop.

So can you make money with a CNC machine? The answer is yes – if used correctly and regularly maintained, they can produce excellent results for your business by providing precision parts at much faster speeds than would otherwise be possible by manual machining alone. However, it’s important to remember all the drawbacks discussed above before making such an investment to maximize its potential return on investment.