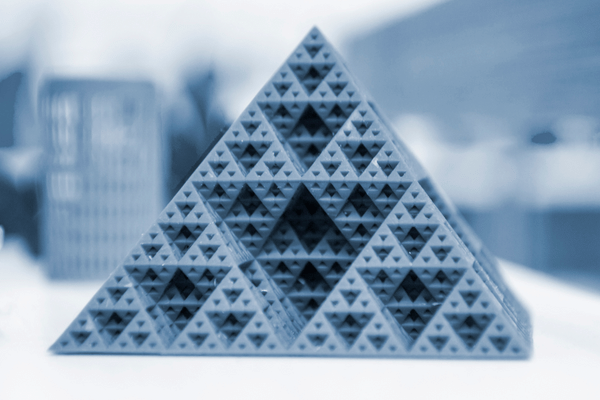

Stereolithography (SLA) is a rapid prototyping process to quickly and accurately create 3D models of parts and prototypes. Stereolithography is non-contact and creates objects with high accuracy, fine surface finish, and smooth features compared to other additive processes such as Fused Deposition Modeling (FDM).

What is Stereolithography (SLA)?

Stereolithography (SLA) is a type of 3D printing that uses a laser to solidify liquid resin layer by layer. The process can create parts with very fine details and smooth surfaces, and it’s used for prototyping, industrial design, and dental applications.

Since the technology was invented in 1986 by Chuck Hull of 3D Systems, SLA has been used to print parts in industries as varied as aerospace, automotive, and medical devices.

Advantages of SLA printers

SLA printers are an excellent choice for businesses that need to print models with high precision and detail. They are also suitable for those who want a professional-quality prototype with the ability to customize their prints and those who need a 3D printer with high resolution.

The following are some of the key advantages of SLA 3D printers:

High resolution – SLA technology allows you to print objects with high precision and detail. The layer thickness is only 25 microns or less, making it possible to create detailed models.

High-quality prints – SLA printers produce smooth surfaces with no visible lines or joints between layers. This makes them ideal for printing electronics enclosures and other parts with complex geometries that require smooth surfaces.

Customizable – You can use different materials in your SLA printer to create different colors, textures, or opacity levels on your prints. You can also use soluble supports in your prints so that they don’t need to be removed after printing is complete.

The SLA process

The SLA process is a 3D printing technology that uses photopolymers to create objects. This process can achieve extremely high resolution, with layer heights in the range of 0.025-0.4mm (or 0.001-0.016in) possible with some printers. The final model can be produced as a single piece or as multiple parts that are then glued together, depending on the user’s requirements.

The SLA printer uses a laser to solidify a liquid resin layer by layer until an object is formed. This process is known as stereolithography, hence the name ‘SLA.’

Stereolithography (SLA) printing materials

SLA printing materials are typically cured with UV light. However, many other types of materials and methods for curing them exist. Some of the most common include:

photopolymers: These are typically cured with light in a process called photopolymerization.

Thermoplastics: These are commonly cured at high temperatures in an oven. The result is a strong, durable plastic part with a matte finish.

Thermosets: Thermosetting plastics require chemical reactions to cure and create a rigid part that can’t be remelted or recycled.

Limitations of Stereolithography (SLA) printing

The main limitation of stereolithography is that it can only be used to create solid objects. This means that it cannot be used to print out hollow objects. However, this is not a problem as most objects that are printed using this technology are solid anyway.

Another limitation of stereolithography is that it can only produce parts with a maximum thickness of 0.5 inches. While this may seem like a significant limitation, most parts that can be printed using stereolithography are thinner than this anyway.