In this blog, we will discuss the requirements of wire EDM machining and a few basic steps to get started in CNC wire EDM machining. Here are a few things you need to know about Wire EDM Machining.

1. Analyze and review drawings

Before starting EDM machining, you must ensure that the drawing has been done correctly. This is an important step because it will help prevent any mistakes from occurring later in the process. It is also important to ensure that the part will be produced promptly, which requires having all of the information about the job at hand.

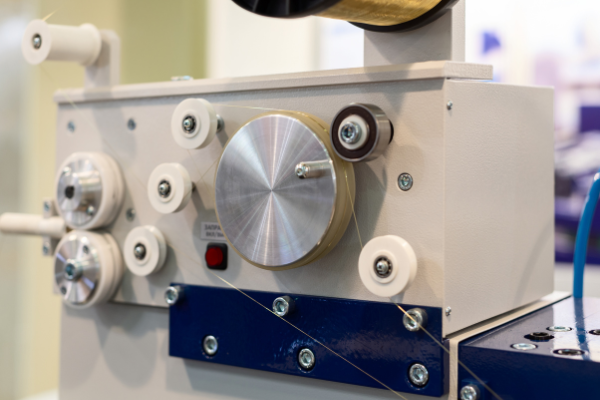

2. Set up your machine

Once you have analyzed and reviewed the drawings, it is time to set up your machine. This involves setting up all the tools and equipment needed for EDM machining. This includes everything from power supplies to water cooling systems and vacuum pumps. You should also check all of the settings on your machine before starting work on any parts so that everything runs smoothly during production.

3. Prepare your part for EDM machining

Before cutting into your part with an EDM machine, you must prepare it for this process by sandblasting or etching off any scale or rust from its surface using an abrasive blast media such as silicon carbide or aluminum oxide grits at low pressures (less than 500 psi). This will help ensure that there are no impurities left on the part’s surface after being cut into by

Programming Considerations

1. Determination of mold clearance and transition circle radius

One of the first things that must be determined when programming a part is how much room there is between the cutter and the part being cut (mold clearance). If there isn’t enough room between the cutter and the part being cut, there may be damage to either or both pieces of equipment. This would require them to be repaired or replaced before further work on your project.

The transition circle radius is another consideration when determining whether or not enough room exists for safe operation during CNC machining operations. A transition circle radius is an arc that extends from one point on an object to another point on an object with a specified radius.

2. Calculate and compile the processing program

This is the first step in CNC programming. You need to calculate all the necessary information, including feed rates, speeds, tool paths, etc., to create a program that can be compiled onto your machine. This can be time-consuming, but it’s important because it ensures that the end product will have little variation from what was planned by you as the programmer.

3. Threading process paper tape and proofreading paper tape

Threading Process Paper Tape

Threading process paper tape is made from a special type of paper that a computer system can read. The computer reads the patterns on the tape and inputs them into its system. The pattern on the threading process paper has been specially designed for this purpose. Each pattern represents instructions for cutting parts or performing other functions within a computerized machine tool or another piece of hardware.

Proofreading Paper Tape

Proofreading paper tape has no special design or pattern and does not contain information about how to operate a specific piece of hardware. However, it does have clear markings so that you can see where each line starts and stops to verify that all instructions were entered correctly into your program file without any mistakes being made during this process.

How To Reduce The Human Error In Wire EDM Machining

Human error in wire EDM machining is one of the most common problems in this field. The reason behind this is the fact that it is a very manual process and requires a lot of attention and concentration.

The best way to reduce human error in wire EDM machining is by following some simple procedures:

Step 1: Always work with a checklist or make sure you know what you are supposed to do before starting work on any particular project. This will help you avoid mistakes and increase productivity as well.

Step 2: Always use the same tool for all operations. For example, if you use a grinding wheel to shape the tip, always use only one grinding wheel for all operations. This will help avoid any mistakes or accidents during the process.

Step 3: Use a microscope when needed for greater precision and accuracy when working on small parts where it is difficult to see clearly without magnification. It can also be used for checking dimensions during machining operations to ensure they are within tolerances before proceeding further with other steps of the production process. This will also reduce human error in wire EDM machining by ensuring that all parts meet specifications before proceeding further with other steps of the production process.

Conclusion

Wire EDM is one of the most widely used and accepted metal cutting processes in industries and manufacturing companies in different sectors. The process being used for years for metal part designing, forming, and deforming. Wire EDM is an effective method for working on parts that cannot be produced with conventional machining processes; in this article, you’ll learn about the top benefits of Wire EDM. Hope you’ll be satisfied with our answer.