[lwptoc]

What is a CNC machine, and what does it do?

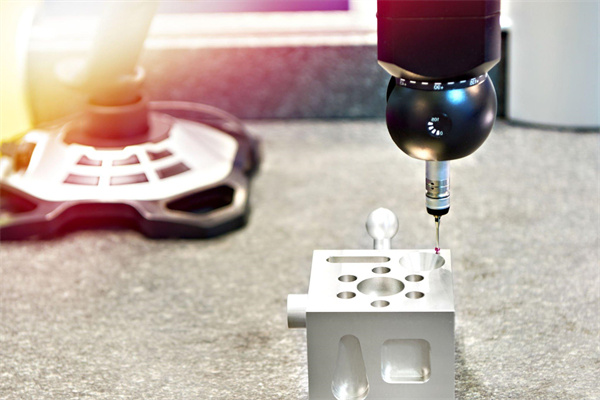

Modern manufacturing operations rely on Computer Numerical Control (CNC) machines to produce high-precision parts with extreme accuracy. CNC machines are programmable tools driven by computer software, allowing engineers and operators to create complex geometries easily. This article explores what a CNC machine is and how to operate it, making it the perfect reading for those looking to expand their knowledge in the field of manufacturing.

Simply put, a CNC machine is a machine tool run by a computer program designed to produce precise parts, usually metal or plastic components. These computers are programmed with commands that dictate the movements of machinery, such as cutting tools like drills, lathes, routers, and grinders. The CNC machine takes these commands from the software and executes them accordingly to create the desired product or component.

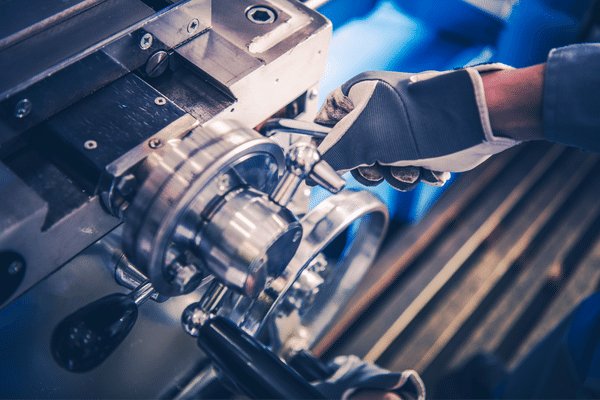

In terms of operation, a CNC machine can be operated manually or through computer-operated systems, depending on its size and complexity. For smaller applications such as hobbyists’ projects or small prototypes, manual control is possible through direct manipulation of buttons and switches on the machine itself or through interaction with an attached controller box that allows for more complex programming and control functions. On larger devices like industrial production lines, CNC machines must be operated by interfacing directly with a computer system. This process involves writing programs in code that tell the machine what commands to execute and how they should be performed – though this process can often be simplified by using CAD/CAM software explicitly designed for CNC machines. Once programmed correctly and tested thoroughly, these commands are sent to the CNC machining centers, where they can be executed automatically – producing accurate results every time without any human intervention required!

When operating a CNC machine, several safety measures must be considered. Due to their robust nature and fast operation speeds, it is essential to maintain a proper distance from the moving parts to avoid injury from contact with hot metal chips or other debris created during machining processes. It is also essential to ensure adequate ventilation due to dangerous fumes created during machining processes like welding – protective clothing should always be worn when operating any machinery to protect both personnel working in proximity and anyone located nearby from potential health risks caused by hazardous materials.

Overall, understanding how to operate a CNC machine is essential for anyone looking for success in modern manufacturing operations today! Its ability to produce precise parts over long periods without needing continuous human presence or intervention – combined with its proven efficiency compared to traditional machining methods – makes this technology an invaluable asset within any industry seeking advanced production capabilities at reasonable costs!

How to operate a CNC machine

Operating a CNC machine can be intimidating, but it doesn’t have to be. Working with a CNC Machine can become a seamless and straightforward process with the correct information and guidance. In this blog post, I will provide the information you need to understand how to operate a CNC machine correctly and safely.

What is a CNC Machine?

A Computer Numerical Control (CNC) machine is an automated tool that uses computer programming inputs to control various machining operations. It is widely used in industrial production for cutting and shaping metal and other materials with high precision and accuracy.

The Benefits of Using a CNC Machine

A CNC machine can save time and money compared to manual machining processes. It also provides greater precision and accuracy than manual machines, making it ideal for applications where precise measurements are essential. Additionally, CNC machines can handle complex shapes that are difficult or impossible to achieve with manual machining approaches.

How to Set Up a CNC Machine

When setting up your CNC machine, you must first decide which type of controller you want to use. This could either be a G-Code or M-code controller. Once you’ve chosen the controller type, follow the manufacturer’s instructions on setting up your specific machine model. This should include mounting the spindle motor, connecting motors and axis drives, and attaching accessories, such as coolant pumps or air compressors, if necessary. After all, components are connected, ensure that all software drivers are correctly installed before continuing with the operation of your CNC machine.

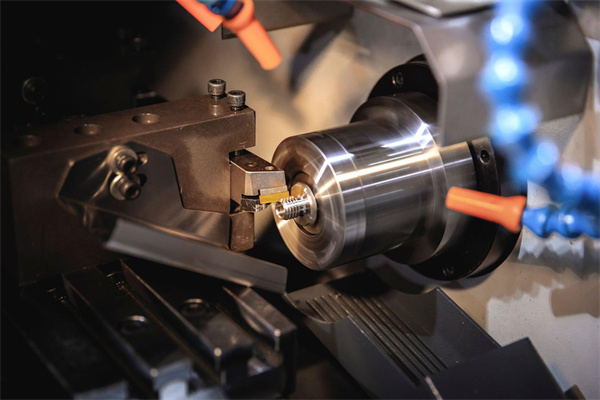

How Does A CNC Machine Work?

Once your machine is set up correctly, you must program the commands into the system using either G-code or M-code, depending on what type of controller you’re using (see above). This involves entering commands such as feed rate and spindle speed into the control panel to know how quickly or slowly it needs to move around each axis while cutting material. The controller then interprets these commands into electronic signals, instructing motors attached to each axis (x-axis, y-axis, and z-axis) on how quickly they should rotate for the spindle head (tool) to move appropriately when cutting or shaping material at hand.

Safety Considerations When Operating A CNC Machine

It is important to understand safety considerations when operating machinery, including a Computer Numerical Control (CNC) machine. These machines pose risks if not operated properly due to their nature of designing parts accurately at high speeds. Therefore operators must keep these safety considerations in mind when working with them:

• Wear protective clothing such as eye goggles/protective glasses when working near moving parts;

• Make sure that all safety guards are in place before starting operation;

• Ensure that tooling such as drill bits and end mills are compatible with the material being machined;

• Keep hands away from moving parts during operation;

• Always check feeds & speeds against manufacturer recommendations before running the job;

• Regularly inspect tools for wear & tear; replace worn tools immediately;

• Shut off the power immediately after the job has been completed;

• Disconnect the power source before making adjustments or cleaning the work area;

• Store tools safely after use until the next job session begins;

• Wear ear protection if noise levels exceed 85 decibels;

• If ever unsure about anything related to operating your particular model of CNC machine, contact the manufacturer for clarity on best practices for safe operation by available documentation provided by them or consult knowledgeable personnel who specialize in this area for advice on proper usage guidelines & procedures pertaining specifically towards larger industrial models like those found in factories etcetera.

Conclusion

In conclusion, understanding how to operate a Computer Numerical Control (CNC) machine correctly is essential for ensuring safety while achieving maximum efficiency from its usage within industrial production settings since its capabilities far exceed that which manual processes can produce regarding accuracy & repeatability when dealing with intricate shapes commonly found within those contexts due primarily towards its automation features thus making it a precious asset provided all available precautions associated towards its practical usage have been satisfied beforehand!

Tips for getting the most out of your CNC machine

Operating a CNC machine can be both complicated and time-consuming. However, the more you understand about the craft, the easier it becomes to leverage its full potential. To help you get the most out of your CNC machine, here are a few tips to keep in mind:

1. Learn the Basics

– Before operating your CNC machine, ensure you know how it works. Read the user manual carefully and learn the settings, features, and functions. Additionally, if possible, attend a class on basic programming to understand better how to use different types of software with your machine.

2. Develop an Operating Plan

– Create an operational plan for yourself so that you know exactly what steps must be taken to complete each job efficiently and accurately. Having a plan will also help prevent misunderstandings between workers and ensure that each job is completed correctly.

3. Use Quality Materials

– It’s essential to use quality materials when operating a CNC machine as they will help ensure that your work remains accurate and precise over time. Ensure to follow manufacturer instructions when selecting materials compatible with your specific type of CNC machine.

4. Know Your Limits

– While some machines may allow for more intricate designs than others, it’s important to remember not to push beyond what your specific machine can do to avoid mistakes or faulty parts down the line. Also, be aware of how much pressure can safely be applied when cutting through different materials, and do not exceed this amount during operation.

5. Stay Organized

– Keep your workspace organized and free from clutter to ensure everything runs smoothly during production. This includes ensuring all tools are safely stored away when not in use and keeping all safety equipment comfortably within reach should there ever be an emergency while working with your machine.

By following these tips for getting the most out of your CNC Machine, you’ll be able to produce higher-quality results faster and with greater accuracy—allowing for increased productivity overall! Keeping up with maintenance schedules on both the hardware and software side is critical for extending the life of any CNC Machine and ensuring accurate results for years to come, so don’t forget to check up on those too occasionally!

Common mistakes people make when operating a CNC machine

Operating a CNC machine is not a task that should be taken lightly. Despite their reputation for being precise and reliable, several common mistakes can still be made when operating these machines. In this blog post, we will outline the most common mistakes people make when using a CNC machine and provide helpful tips on avoiding them to ensure optimal performance and results.

The first mistake people often make when operating a CNC machine is failing to read the manual before beginning work. Many operators assume they can jump in and start working without understanding the safety guidelines or knowing how to operate the machine properly. This could lead to potentially dangerous situations or costly errors if done incorrectly. It’s essential for operators to thoroughly read through the manual before beginning any work on a CNC machine.

Another mistake people often make is not correctly securing the material or tools used with the CNC machine. Materials and devices must be appropriately guaranteed so they don’t become loose during operation, which could result in damage or injury. Additionally, operators should always double-check that all components are tightened correctly after each use, which can help prevent future problems.

In addition to reading the manual and properly securing materials and tools, operators should also pay close attention to their surroundings while working on any CNC machine. This means taking note of any nearby objects that could get in the way of operation and ensuring that no one else is standing too close while in use. It’s also essential to ensure that all moving parts have been turned off before starting any new job so as not to cause accidents or breakages due to unexpected movements from already running parts.

Finally, it’s essential for operators to regularly check for wear and tear on their machines and replace any worn components as necessary in smooth order operation at all times. Regularly lubricating moving parts can also help reduce wear and tear over time and extend the life of your CNC machine.

Understanding how your CNC machine operates is vital to avoiding potential mistakes while using it safely and effectively. Taking the time to read through manuals carefully, secure materials properly, pay attention to your surroundings, and regularly check for wear and tear will go a long way toward ensuring you understand how best to operate your machine while avoiding costly errors down the line.

Troubleshooting tips for common problems with CNC machines

CNC (Computer Numerically Controlled) machines are vital to many businesses and industries, allowing for precise and efficient manufacturing processes. Those operating a CNC machine must know how to troubleshoot common problems to get the most out of its benefits. In this blog post, we will provide some tips on diagnosing and solving some common issues with these machines.

The first step when troubleshooting a CNC machine is to understand what could be causing the problem. The issue can often be easily identified and corrected before any further maintenance or repair is required. Common causes of CNC machine issues include power issues, mechanical malfunctions, or software problems. Additionally, it is essential to look at the user manual or technical documents for your specific machine as they may contain information on potential faults that can occur with your particular model.

Once you have identified potential causes for the problem with your machine, you should begin by performing basic maintenance tasks such as cleaning and inspecting moving parts or replacing worn components. This ensures all features function correctly and may help prevent future problems. If these basic steps do not fix the issue, more complex repairs, such as realigning mechanical components or reprogramming software settings, may need to be carried out. In both cases, consulting an experienced service member familiar with CNC machines can provide invaluable advice on getting back up and running quickly and safely.

If more advanced repairs are needed, it is often beneficial to contact a local service center specializing in CNC machinery for further assistance and advice. These experts can carry out more complicated repairs using specialized tools and techniques that are unavailable under normal circumstances. Furthermore, they will also be able to provide valuable support in diagnostic testing if needed, which can help pinpoint the exact cause of any faults or malfunctions occurring with your machine.

Finally, it is essential to ensure regular maintenance checks are carried out on your CNC machine to keep it running at peak performance levels throughout its entire lifespan. This includes checking all internal components such as bearings, gears, belts, etc., and ensuring that all software settings remain up-to-date with all necessary updates applied when needed. Doing so helps keep costly repairs at bay and minimizes downtime, meaning operations run smoother for more extended periods without any hiccups on the way!

Overall, understanding how best to troubleshoot common problems associated with CNC machines can prove invaluable in keeping them running smoothly and efficiently over their lifetime – saving time, money, and effort in the long run! By following these simple guidelines outlined above, you should have no trouble finding success when working with these incredible pieces of technology – giving peace of mind while continuing day-to-day operations without interruption!