[lwptoc]

What is a CNC machine, and what does it do

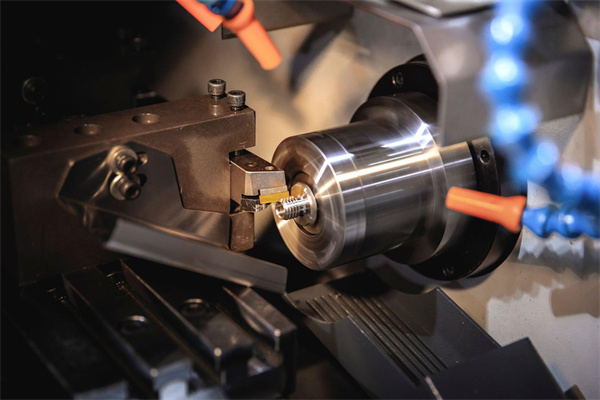

A CNC machine is a computer numerically controlled machine that can be programmed to move materials and components according to specific instructions. It is an automated machine used in many manufacturing processes, such as cutting, shaping, drilling, and milling. CNC machines have become integral to the manufacturing industry because they provide accuracy and repeatability while increasing production speed.

CNC machines can be operated either manually or automatically. Manual operation requires a skilled operator to enter code into the machine’s control panel that specifies the movements of its axes and the other parameters of its function. Most modern CNC machines are computer-controlled and use specialized software for generating tool paths. This allows for greater flexibility in operations since any changes made to the program will immediately affect how the machine operates.

CNC machines are known for their accuracy and repeatability because each job’s parameters are programmed into the machine itself instead of done manually by an operator. This eliminates human error, which could potentially lead to poor-quality artistry and costly mistakes. Additionally, CNC technology allows jobs that would have previously taken hours or days to complete, such as complex 3D machining operations, to be completed in much shorter periods – often in minutes or seconds!

So how do you operate a CNC machine? As mentioned, most modern CNC machines are computer-controlled, using specialized software, allowing operators to create tool paths quickly and accurately with minimal effort. The programming language used may vary depending on the model and manufacturer, but all typically involve entering commands into a text-based or graphical user interface (GUI). Once programmed into the machine’s memory, these commands will be executed when instructed by an operator or automated process within the control system.

Before operating any CNC machine, it is essential to understand basic safety precautions, such as not wearing loose clothing around moving parts or interacting with tools while they are driving. Additionally, operators should always wear protective gear such as safety glasses when working with a CNC machine and read through the manufacturer’s instructions before attempting any programming or setup work. Finally, operators should always check their work carefully before initiating any machining operations to ensure accurate results every time!

How do you operate a CNC machine?

Operating a CNC machine can be daunting, especially for someone with limited experience. However, once you understand the basics, the process is relatively simple. This blog post will review the steps to successfully operate a CNC machine to produce high-quality precision components quickly and efficiently.

First and foremost, you must create a computer-aided design (CAD) file that includes all of the specifications for your desired product. This will be used as input in the CNC machine’s software protocols, so it needs to be as detailed and accurate as possible. Once you have your CAD file ready, it’s time to move on to the actual operation of the CNC machine itself.

The first step is to ensure all safety protocols are met. This means wearing appropriate protective equipment such as gloves and eye protection while operating the machine, keeping an eye out for any loose items that could interfere with its function or cause damage during operation, and never leaving it unattended while running.

Once safety precautions have been taken, you can begin laying your project on the machining table by securely positioning material clamps around it. These clamps help keep your material in place during operations so that cuts are made accurately along intended paths or planes of motion. If necessary, due to size or weight constraints, multiple pieces of material may need to be clamped together for secure machining operations.

Next comes programming your CNC machine with instructions from your CAD file, which includes information such as cutting directions, tool selection (drill bit sizes or other cutting tools required), feed rate (how fast the device moves across the material surface), depth of cut (distance through material), coolant settings (if applicable) and more depending on individual applications being machined. Generally speaking, this programming is done before machines are set up but may need adjusting depending on project requirements – though if using pre-programmed files, proper setup should not require further adjustments aside from perhaps starting/stopping points and speeds/feed rates when appropriate.

Following the programming adjustment steps are completed, it’s time to enter run mode – which allows machines to take over their operations based on programmed instructions without needing direct human intervention – once again ensuring everything goes according to plan without having any issues while machining complex shapes into materials! And now that everything has been set up correctly, all there’s left to do is monitor progress moving forward by checking periodically for any errors that might indicate problems within either software or hardware system before finally shutting down once complete – completing successful machining operations!

To conclude, operating a CNC machine does involve some complexity; still, with an understanding of setup processes and safety measures, one can safely carry out precision machining projects quickly and efficiently! Of course, there will always be cases where more advanced techniques may need implementing, but with practice, anyone can become an expert at running these machines quickly!

The benefits of using a CNC machine

CNC machines are an invaluable tool for manufacturers looking to create complex parts quickly and accurately. Not only can they be used to reduce costs and improve efficiency, but they can also help you achieve higher precision than ever before. But how do you operate a CNC machine?

The first step in learning to operate a CNC machine is understanding its essential components and functions. A typical CNC machine consists of three main parts: the controller, the mechanical system, and the software. The controller is the interface between the operator and the machine itself; it takes commands from the operator and translates them into instructions that the machine understands. The mechanical system consists of motors, servos, drive systems, linear actuators, etc., which move axes in a linear and rotary motion to complete a task. Finally, software programs interpret instructions from the controller and send them to the mechanical system so that it can meet its job accurately.

Once you understand these components and their functions, you can learn how to interact with them. This will involve manual controls via buttons or dials and computer control via a G-code programming language. Manual control allows operators to move parts manually. In contrast, computer control utilizes code written in a specific programming language, such as G-code, that tells the machine what steps must be taken to complete a particular task. Many CNC machines come with their proprietary software for writing code, but there are also several open-source solutions, such as LinuxCNC or GRBL.

Learning how to program a CNC machine properly involves understanding CAM (computer-aided manufacturing) software packages and design elements such as 2D drawings or 3D models to accurately create patterns or parts according to specifications set by an engineer or CAD designer. Once an appropriate CAD/CAM program has been chosen for your particular job, you must learn how to write proper code, considering things like tool paths, feeds & speeds, so your finished product meets all desired specifications.

For those who may not have any previous experience with CNC programming languages, many online tutorials on sites like YouTube provide clear step-by-step instructions on how best to approach programming a CNC machine, depending on what type of job needs doing. Additionally, plenty of books on Amazon or other booksellers explain more complex topics explicitly related to different types of machines or programs used within industry settings, such as Mastercam or Autodesk Fusion 360, in detail, a few examples.

Overall operating a CNC machine requires careful attention and knowledge concerning both hardware components and proper programming techniques; taking some time upfront before diving into production is highly recommended if one wishes for excellent results each time!

Things to keep in mind when using a CNC machine

Using a CNC machine can be intimidating, especially for those just starting. Fortunately, with the proper instructions and practice, CNC machines are reasonably easy to use. In this blog post, we’ll go over some essential things to remember when operating a CNC machine so you can get the most out of your experience.

First, it’s essential to understand what a CNC machine is. CNC stands for Computer Numerical Control, which means that all operations are guided by programming rather than manual control. This allows precision cutting and drilling on metal and other materials without manually operating each process step. To use a CNC machine correctly, it’s essential that you first understand how it works before getting started.

Next, reviewing safety protocols when operating a CNC machine is essential. Many risks are associated with using these machines, and understanding how to use them safely is critical. Ensure you are familiar with the safety and emergency procedures outlined in the manual before starting. Additionally, wear appropriate protective gear such as eye protection, hearing protection, and full-length clothing when operating the machine to avoid any danger or injury while working.

Another critical factor when using a CNC machine is correctly setting up parts to achieve optimal results from the job at hand. All setup procedures should be carefully reviewed before beginning any work on the machine, as they will need to be followed precisely for the job to turn out correctly. Additionally, all tools and accessories used during setup must be compatible with your particular CNC machine model; otherwise, they may not function properly or cause damage during operation.

Finally, regular maintenance is crucial for optimal performance over time when using a CNC machine. This includes cleaning off debris from moving parts after every shift and regularly checking levels of lubrication oil on various components, as stated in your manufacturer’s manual. It is also essential to inspect all bolts and nuts periodically for any signs of loosening or wear and tear so that any issues with loose connections can be addressed quickly before they result in further damage or accidents during operation.

Following these guidelines when operating your CNC machine ensures optimal performance throughout its lifetime to continue creating high-quality projects without issue or interruption! So remember: always review safety protocols before operation; set up parts correctly; use compatible tools; and maintain your machinery regularly – these simple steps will help keep your projects running smoothly!

Tips for getting the most out of your CNC machine

CNC machines are an excellent tool for those needing the precision and accuracy of automated machining. CNC (Computer-Numeric Controlled) machines can create intricate parts, components, and products with absolute accuracy and repeatability. But how do you operate a CNC machine? In this blog, we’ll discuss tips to get the most out of your machine and ensure it runs smoothly and efficiently.

The first tip is to familiarize yourself with the machine’s software and controls. Learning how to program a CNC machine is essential for getting the most out of it. If you don’t have experience in programming them, consider taking a class or using online resources to become proficient in this task. Understanding the safety protocols associated with operating the machine and any environmental regulations that may apply in your area is also essential. Knowing these things will help you manage your CNC machine correctly and safely whenever you use it.

The second tip for getting the most out of your CNC machine is to use high-quality materials when creating your components or products. Cheap materials can cause defects in your finished product, which will require more work and cost more money. Investing in top-notch materials upfront will ensure that you get a quality product every time without paying additional costs later on down the line.

You should also ensure your workspace is clean and organized before running any jobs on your CNC machine. Clutter can lead to accidents or errors while working with the machinery, so keep everything tidy before starting a career! Additionally, inspect all tools before loading them into the machine so that they are functioning correctly; this will help prevent issues from arising during operation time.

Finally, always follow maintenance protocols for keeping up with regular cleaning and lubrication schedules for your CNC machine if available from its manufacturer. This will maintain its performance over time by preventing rust buildup or other damages from occurring due to neglectful upkeep practices. Furthermore, having scheduled maintenance checks done by qualified technicians can catch any potential problems early on before they become serious issues that require expensive repairs or replacements.

These are just some tips for getting the most out of your CNC machine; however, plenty of others are available online, depending on your type of machinery. With proper planning, preparation, and maintenance protocols followed regularly, you can ensure smooth operations throughout your lifetime!