When buying a CNC machine for auto parts, you should always choose a manufacturer with a good reputation. These manufacturers can provide you with high-quality auto parts at an affordable rate. Purchasing these parts will help you maintain the quality of your car’s engine. These manufacturers can use CAD/CAM software to create your designs. Also, they can offer you high-fidelity components.

CAD/CAM software

If you’re interested in designing auto parts for CNC machines, you should use the right CAD/CAM software. There are several options for these programs. One of the most popular is MasterCAM, which integrates a powerful CAM solution with full 3D CAD modeling. You can easily change the CAD design without losing the original CAD file. You can also reprogram G-Codes from the software.

CAD/CAM software can vary; some are more versatile than others. You must select the right one for your needs and be aware of the limitations of each one. The software must be capable of working with various file types, and it should be able to import and export files from other applications.

You can also try out free CNC control software. Openbuilds offers machine kits and free CAD/CAM software. Openbuilds’ free software is an open-source alternative. It can import G-code from CAD/CAM software and run CNC machines. It has a clean interface and supports different control boards. It’s also compatible with Windows, macOS, Linux, and other platforms.

Openbuilds is an open-source CNC software with an active community of users. Using it is free and comes with excellent support. It’s a good choice for hobbyists and people who value simplicity. Openbuilds generates G-code and feeds it into an interface between the control board and the computer. A CNC controller board reads this G-code to produce the parts.

HyperMill is another CAD/CAM software package that can be used to create auto parts CNC machines. It has seven modules that can support everything from simple 2D milling to advanced multi-axis machining operations. The software also has a library of post-processing programs. These programs can reduce programming time dramatically.

5-axis CNC machine

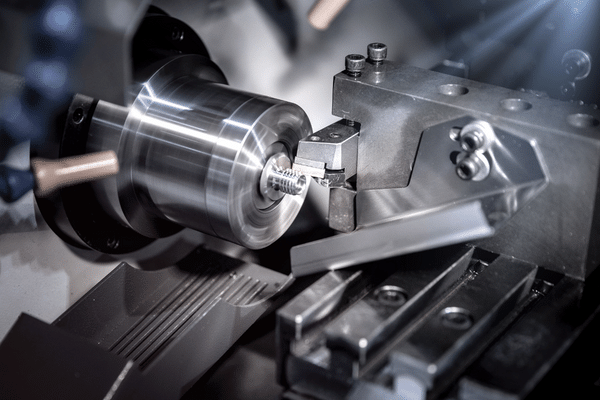

A 5-axis CNC machine is the way to go if you want to upgrade your machining processes. These machines can machine nearly every surface on a part, and they can eliminate the need for multiple setups and special features. The cutting head and extra rotational axes allow them to reach five sides of a part simultaneously, meaning fewer setups and re-fixturing. A 5-axis machine also reduces waste, resulting in lower labor costs.

A 5-axis CNC machine is ideal for producing parts in high-volume production. It can be used for many different applications, from aerospace to the automotive industry. In these industries, precision is essential, and parts need to meet tight tolerance requirements. Additionally, a 5-Axis machine can handle parts with complex shapes and high volume.

This type of machine is also capable of producing custom robotic parts. It can also produce customized jigs and effectors. With recent technological advancements, the applications of these machines are becoming more sophisticated. And if you’re in the market for one, don’t hesitate to call us. We’ll be happy to answer any questions you have about precision 5-axis machining.

A 5-axis CNC machine requires intricate programming. It must accurately calculate a cutting tool’s trajectory and ensure its movement’s accuracy. Additionally, it requires highly skilled labor to perform this process. Because of this, 5-axis machines require professional maintenance and training. However, the good news is that most 5-axis CNC machines come with maintenance contracts. Otherwise, they can turn into expensive paperweights.

A 5-axis CNC machine is ideal for the production of complex geometries. It allows for better accuracy than traditional machining methods. It’s important to note that a 5-axis machine will require more space in your workshop. However, a 5-axis machine can also be used to replace dual setup operations.

High-fidelity components

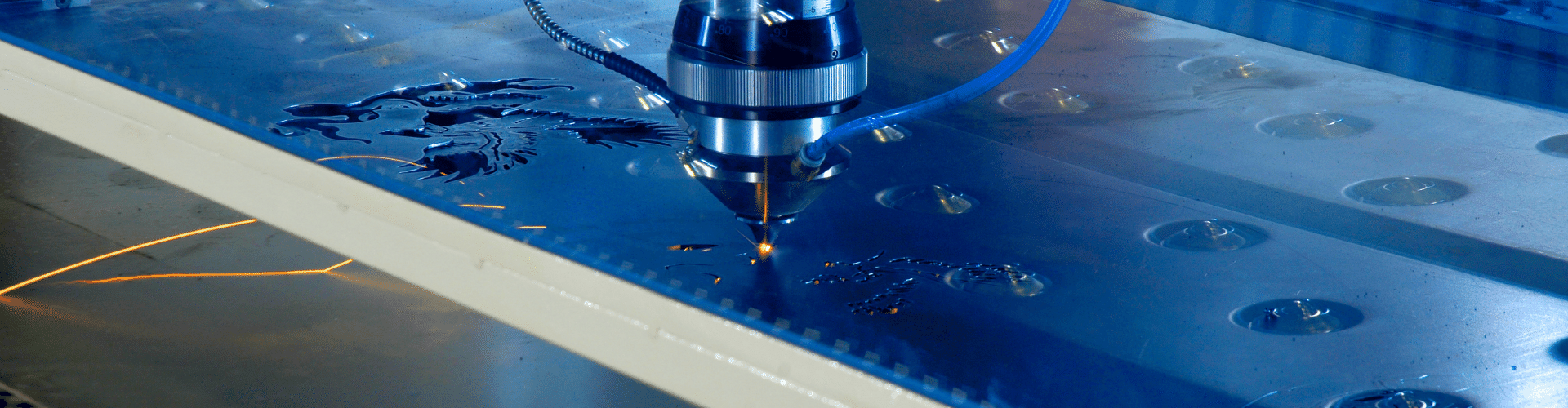

CNC machines are used to fabricate automotive parts in an automated process. This process allows for greater precision than manual labor and allows car manufacturers to manufacture custom parts with high accuracy. These machines can produce high-fidelity prototypes for various components, from the smallest detail to the largest part. In the automotive industry, high-fidelity prototypes are essential to ensure the driver’s highest level of performance and safety.

High-fidelity prototypes allow engineers to test their ideas before they produce the parts. Because high-fidelity prototypes are more accurate, it is easier to determine how well the parts fit and function. One of the most common ways to create prototypes is through 3D printing. With this method, detailed plastic parts can be created quickly. They can then be tested in real-world environments.

A good CNC machine shop should incorporate quality control into the prototyping process. This is essential to ensure high-fidelity components are produced promptly. They should also provide zero error tolerance and ensure that the finished products meet design specifications. Finding a CNC shop that communicates well with designers and customers is also important.

The automotive industry has used CNC machines to fabricate cylinder and engine blocks. These engine parts serve two important functions in the vehicle. The cylinder blocks are made of metal, and the heads are made of plastic. Cylinder blocks are usually built of aluminum, which is highly conductive. Aluminum cylinder heads, in particular, expel a lot of heat from the combustion chamber.

Artificial Intelligence

Using AI in CNC machines for auto parts production can reduce machine downtime by improving fault detection and repair. With this technology, a CNC machine can detect and repair faults automatically, saving operators countless hours of troubleshooting time. Additionally, it can diagnose machine faults more accurately, increasing machine productivity and reducing costs.

AI enables better machine efficiency by analyzing data from many different sources. It can optimize production processes and schedule downtime by analyzing usage rates and determining how to maximize productivity. It can also help machine maintenance teams by analyzing diagnostic and prescriptive data. It can relay this data to machine operators and suggest performance and timing changes.

Machines equipped with AI can also assist in the design of feedback mechanisms that will help self-driving cars. For instance, a precision CNC program can shut down a car when it detects its owner has left it running. This shutoff code is generated with AI-assisted CNC automotive.

Using AI in CNC machines for auto parts is crucial for the future of self-driving cars. With these autonomous vehicles, CNC machines will need to produce more accurate and faster parts. They can also monitor the quality of the end product and make adjustments automatically. This will help improve these machines’ performance and the cars’ quality.

While the use of AI in CNC machines is still in the early stages, it has already changed the world of manufacturing and technology. For instance, AI-powered machines can respond to voice commands and make decisions on repetitive tasks. This will lead to improved quality and production for manufacturers and buyers alike. Machine learning can also improve production capacity and cut costs per unit.

Need quality cnc machining service in China

As a full-service precision machining house, ETCN has been offering CNC machining to customers with precision machining and high quality service.