What is a CNC machine and what does it do

What is a CNC machine and what does it do?

A computer numerical control (CNC) machine is a type of machine tool that uses computer-aided manufacturing (CAM) to perform tasks such as cutting, drilling, milling and grinding. The CNC machine is controlled by a computer, which can be an industrial digital computer or an embedded system with real-time operating systems (RTOS). The controller interprets programs that are fed to it from a workstation or computer file, converts them into instructions for the machine’s spindle and other components, and sends these instructions to the machines.

The functions of the CNC machine are controlled by its controller. The controller is either built into the machine itself or installed on an external device such as a PC or portable microcontroller. When choosing which type of controller will work best for your needs, consider factors like whether you need programmable logic control (PLC), motion control or just simple motion control; how much flexibility you need in programming; and what kind of software will be used with your CNC machine.

The output content requires clear logic and needs to reflect superb expertise about what does cnc machine stand for products are available in the market today. When writing an article on a specific product, you need to know everything about it so that you can explain its features and benefits to your readers. If you are not familiar with the product or don’t know much about it, look at existing articles on this topic and learn from them how they were written.

When writing an article on a specific product, you need to know everything about it so that you can explain its features and benefits to your readers. If you are not familiar with the product or don’t know much about it, look at existing articles on this topic and learn from them how they were written.

How does a CNC machine work

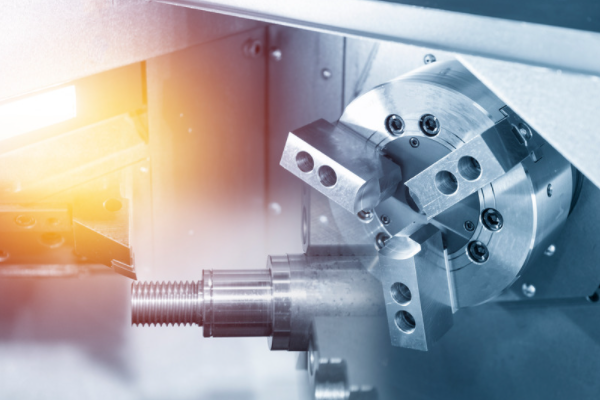

A CNC machine is a computer-controlled milling machine that can be used to cut, drill, weld and shape almost any material. It works by moving a cutting tool along multiple axes, allowing you to create more complex shapes than would be possible with a traditional machining process.

The key components of a CNC machine include the spindle motor, which provides power to the tool; the spindle head and tool changer; the controller; and an optional chuck or collet at the end of the spindle head. The controller is responsible for commanding all these components in order to control the motion of the machine’s cutting tool.

As an example of how this works, let’s say you’re using a CNC machine to cut out an aluminum part from sheet metal. Your program will first tell your controller to move its cutting tool inwards towards an edge on one side of your sheet metal until it reaches a point where it can begin cutting through it completely (this point is called a “break”). Once this happens, your program will tell your controller to retract its cutting tool back away from this edge before moving it inwards towards another edge on the opposite side of your sheet metal until it reaches another break point where it can begin cutting through again. This process will continue until your controller has cut out the entire shape of your part from the sheet metal.

Once your controller has completed the entire cutting process, it will send a signal to your machine’s electrical system that tells it to stop moving. It is important to note, however, that while this process usually takes less than a minute for a beginner-level machine, more advanced machines can take as long as 15 minutes or more depending on the complexity of the part being cut out.

The different types of CNC machines

CNC stands for Computer Numerical Control. It is used in the manufacturing industry to produce precision parts, components and assemblies. There are many different types of CNC machines that can be used to create a wide variety of shapes and forms.

The first type of CNC machine is a horizontal milling machine. This type of machine is able to cut, drill, grind and perform other functions using tools placed on its table. These machines are often used to make metal parts such as gears or bars.

The second type of CNC machine is a vertical milling machine. These machines are also able to perform many different functions but with less accuracy than horizontal milling machines because they only have one axis (the X-axis). They cannot move up and down like horizontal machines can so they can only cut along one plane at a time which makes them less flexible than their horizontal counterparts. However, they are still very good at making intricate cuts like holes or grooves into metal surfaces because they have more power than other types of machines which allows them to do things quickly without overheating (which would damage sensitive electronic parts).

The third type of CNC machine is known as a wire EDM machine (electrical discharge machining). These machines use electricity to cut through metal and are commonly used to make small-scale or intricate parts, like jewelry. They use a wire that is fed through an electrode into the material which causes it to melt at a specific point and creates the desired shape.

The fourth type of CNC machine is known as a laser cutting machine. These machines use a high-powered laser to cut through material, which allows them to make extremely precise cuts without damaging the surrounding area.

The benefits of using a CNC machine

The benefits of using a CNC machine

A CNC machine is an essential tool for any workshop or manufacturing facility. It’s a computer-controlled device that can be used to cut, drill and mill a variety of materials.

CNC machines are used in the manufacture of everything from furniture to cars and airplanes, as well as for home improvement projects like woodworking. They can also be used for precision cutting of stone surfaces and glass. CNC machines are also used during product design and development by creating prototypes from 3D models, allowing companies to test new designs before manufacturing them with traditional methods such as injection molding or die casting.

Here are some reasons why you should consider investing in a CNC machine:

1) Improved accuracy: Because the machine performs all steps automatically, it’s easier for operators to achieve consistently high quality results. This means less waste due to poor machining practices; therefore, lower production costs overall because there is less need for rework or replacement parts due to poor quality control measures on standard milling machines (which require constant manual intervention).

2) Increased productivity: Because they’re so versatile, these machines can do more than just mill products; they can also perform complex drilling operations (such as holes drilled through metal plates) which can be used to create holes in a variety of shapes (e.g., square, hexagonal, etc.) that are difficult or impossible for standard milling machines to achieve. This means manufacturers can produce more parts faster without increasing their labor force or purchasing additional equipment.

3) Reduced costs: The fact that these machines can do more than just mill products means manufacturers don’t have to purchase additional equipment. This means they save money on labor and maintenance costs, which in turn allows them to pass those savings on to their customers.

How to choose the right CNC machine for your needs

1. Determine your budget

Before you start shopping for a CNC machine, it’s important to know how much you’re willing to spend. This will help you narrow down your options and find the best product for your needs. If you have a tight budget, then you’ll want to look for a cheaper option that still has enough power and speed to get the job done.

2. Identify what materials you’ll be working with

The type of material that you’re cutting will determine which kind of machine is best for the job. If you’re working with soft materials like wood or foam, then a slower machine might work better because it won’t wear out as fast as a faster one would. However, if you need something more powerful that can cut through metal or stone then look into getting an industrial-grade machine instead!

3. Research reviews from other users

Reading reviews from other users is an important part of choosing any product online because it helps us understand how well it works in real life situations rather than just relying on marketing copy alone (which is always biased). You’ll want to check out what other people have said about their experience with this brand and model before making any decisions about buying one yourself.” 4. Check out how long the warranty is on the machine You’ll want to make sure that it’s a decent length of time, especially if you’re buying a commercial-grade one. Make sure that they offer at least a year of coverage in case something goes wrong with your purchase!

5. Check out the return policy You should also make sure that you can return a product if it’s not what you expected or doesn’t work well for you. There are a lot of different types of machines out there, which means there’s no guarantee that any one will be perfect for your needs.

The cost of owning and operating a CNC machine

What Does CNC Machine Stand For?

CNC stands for Computer Numerical Control. A CNC machine is a piece of equipment that can be used to create models, prototypes, and parts using a variety of materials.

CNC machines are often used by companies looking to manufacture a large amount of custom products in a short period of time. They can be very expensive and require a lot of training to use properly. It’s important for companies considering buying this type of machinery to understand exactly what they’re getting into before making the purchase.

Owning A CNC Machine: What You Need To Know

If you’re thinking about buying a CNC machine for your business, here’s what you need to know about owning one:

1) They’re Expensive – The first thing anyone should know about owning a CNC machine is that they cost quite a bit of money. If you’re thinking about purchasing one without knowing how much it costs or how much it will cost to operate over time, then you might want to rethink your plan because these machines aren’t cheap! The average price tag on these machines is around $20,000-$25,000 depending on which model you choose (and there are many). So if you don’t have the money to spend on a CNC machine, then you might want to think about getting another type of equipment instead. If money isn’t an issue for you, then that’s great! You can start looking at different models and brands so that you can make an informed decision.

The next thing you should think about is the cost of operating the machine. Just because it’s a CNC machine doesn’t mean that it’s going to be cheap to use! Some models require electricity and others don’t, but no matter what kind of CNC machine you buy, there will be ongoing costs associated with running it.