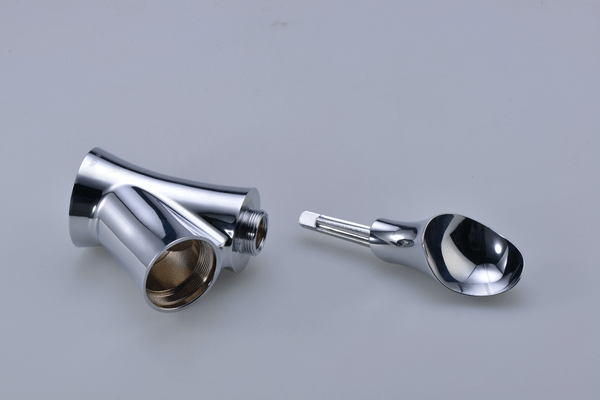

Teflon is a popular material used in manufacturing. This type of material is easy to clean and maintain. It also exhibits excellent electrical properties. These include high insulation resistance and low dielectric constant. These properties make Teflon machined parts a good choice for liquids applications.

PTFE

Teflon is a highly resistant polymer that is often used for fabricated parts. This substance is used to protect against wear and tear, staining, and corrosion, and it is FDA approved. It is also used in food packaging and manufacturing. Despite its use in manufacturing, Teflon and PTFE are still not entirely toxic to humans.

The US EPA has registered PFOA as a known hazard in air and water, and is conducting toxicity assessments for PFOA-coated items. Several US States have also listed PFOA as a known toxin, and have limited corporate contamination with the substance. Furthermore, the United Nations Chemical Review Committee has recommended adding PFOA to the list of banned chemicals.

Exposure to PTFE fumes is potentially toxic, and inhalation of the PTFE gas is associated with polymer fume fever, or “Teflon flu,” which is characterized by chills and sore throat. Luckily, polymer fume fever is relatively short-lived and typically resolves on its own. However, polymer fumes can lead to more serious conditions, including pulmonary edema.

The company behind PTFE has faced lawsuits claiming illegal dumping of toxic chemicals. The company recently agreed to pay $671 million to resolve 3,550 personal injury lawsuits. The plaintiffs in these cases were exposed to PFOA through their drinking water. This is because PFOAs are found in drinking water as far as 413 miles from the plant.

Despite PFOA being banned, the chemical remains in the environment, and is found in wastewater and industrial waste. Furthermore, it is found in household dust and microwave popcorn bags.

PFOA

The chemical PFOA is a very common ingredient in everyday consumer products. However, it has some very serious side effects and is toxic to humans. The chemical is a persistent organic solvent and has the potential to get into the air, water, and soil. It is also known to accumulate in the bloodstream of people who are exposed to it.

PFOA was originally used to create non-stick kitchenware, paints, and firefighting foams. But due to contamination concerns, the industry has phased out the chemical in favour of other PFAS chemicals. Although ‘new’ PFAS chemicals were presented as safer, a number of recent studies indicate that the chemicals in these products are still harmful to humans.

PFOA has been linked to various health conditions, including kidney, testicular, and bladder cancer. Moreover, PFOA does not break down very well by natural processes, so it persists in the environment for a very long time. This has led to the EPA to classify PFOA as a probable carcinogen and urged companies to phase out its use by 2015.

PFOA has been found in food, drink, and water. PFOA can be stored in the body for long periods of time, affecting organs such as the thyroid, liver, and immune system. It can even adversely affect the health of pregnant women and their infants. It is not known whether PFOA causes cancer, but the American Cancer Society has reported that there is a link between PFOA exposure and kidney cancer.

While the chemical is toxic, its use is strictly prohibited in many countries. In the past, manufacturers used it to apply non-stick coatings to cookware. The amount of PFOA found in the finished product was so small, it could be undetectable.

PTFE deforms under extreme pressure

The phase transition temperature of PTFE is related to its reversible deformation. The two processes are related to each other and have the same mechanism. The temperature at which the phase transition occurs is also correlated to its critical strains. PTFE exhibits a wide range of phase transition temperatures, which are related to their corresponding mechanical properties.

The mechanical behavior of PTFE under high and low strain rates has been studied. It has bilinear dependences on the logarithms of strain rates and increases yield strength with higher strain rates. At high strain, PTFE’s critical strain is reduced. This behavior is described by a modified constitutive model. The predictions are compatible with the experimental results.

This new family of products was developed by Industrial Plastics & Machine. The resulting product features enhanced wear resistance, fair chemical resistance, and good compression resistance. It also offers self-cleaning capabilities. This reduces maintenance costs. Further, it reduces the downtime of manufacturing operations.

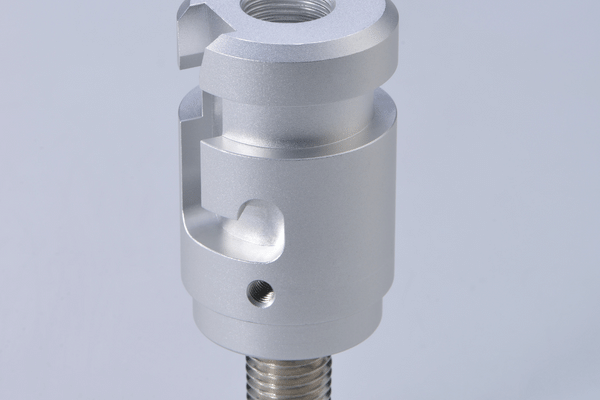

PTFE is a versatile material that has many applications. It is resistant to high temperatures and chemicals, and it has low friction. It is available in opaque black or white and comes in many different surface finishes. In addition, it can be machined with tight tolerances and small radii.

PTFE is an excellent material for temperature probes because of its dielectric strength of 48KV/mm and volume resistance of 1018 Wcm. This property means that PTFE thermometers will not take up as much energy as a steel probe. Further, PTFE probes have good looks and clean lines, which are comparable to metallic probes.

PTFE is a slippery polymer substance

PTFE is a slippery polymer that has a high melting point and is resistant to heat, chemicals, and sunlight. PTFE has one of the lowest coefficients of friction of any substance known. It also has a high abrasion resistance and high tensile strength. Despite its low friction, PTFE is still very slippery to the touch.

One of the most common uses for PTFE is in insulating computer and aerospace components. Its low coefficient of friction and high resistance to high temperatures and chemicals make it a perfect material for insulating components. PTFE has a number of applications, from kitchen utensils to high-tech medical equipment and implants.

PTFE is manufactured by making pellets. The pellets are then processed into many shapes, such as billets or precasts. During this process, the PTFE is heated to temperatures in excess of 680 degrees Fahrenheit or 360 degrees Celsius. This transforms the powder into a gel-like substance. Once this process is complete, the pellets are shipped to a dealer for cutting into desired shapes.

The process for manufacturing PTFE begins with a chemical reaction in a reaction chamber. In the reaction chamber, the chemical reacts with the initiator and the reaction agent. The PTFE begins to polymerize. As the polymerization process proceeds, it produces heat, and this heat can be absorbed by the reaction chamber. To prevent this heat buildup, the reaction chamber is circulated with coolant around its outsides.

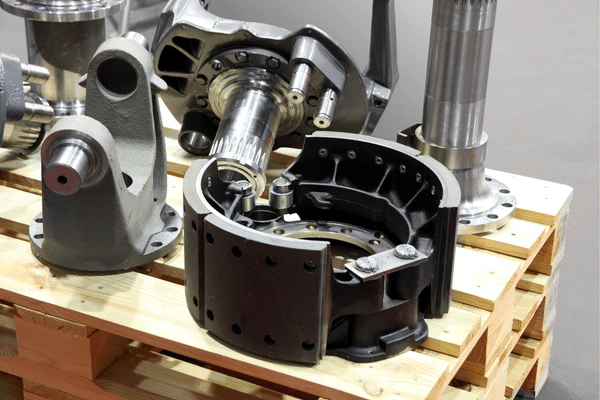

PTFE is a versatile substance that is widely used in manufacturing. It is commonly used for coating pipes, tanks, and pumps. It is also used in insulated coaxial cables used by data providers. Its high melting temperature and high dielectric properties make it a suitable material for insulating cables and connector assemblies. It is also used for filtration and is highly resistant to harsh conditions.

PTFE is a subgroup of PFOA

Teflon is made of a compound known as polytetrafluoroethylene (PTFE). PTFE is a high-molecular-weight polymer made from carbon and fluorine. Its high friction coefficient, low electrical polarizability, and excellent dielectric properties make it useful for many applications. Moreover, it is very durable and can be mass produced.

PFOA is considered highly toxic, and the Environmental Working Group has published a report stating that it is linked with cancer and other health problems in humans. EPA data shows that more than 110 million Americans may have been exposed to it at some point in their life. The EPA and many US State governments have imposed restrictions on manufacturers’ use of this chemical, and the EPA has even ordered them to stop dumping it into our public water systems. In addition, PFOA has been phased out of cookware manufacturing. In recent years, a more safe substitute, known as GenX, has been introduced into the market.

Studies have shown that PFOA has been detected in industrial waste, house dust, and microwave popcorn bags. The compound has also been found in water and food, and has been linked to liver and kidney damage in animals and humans. Researchers have also linked PFOA exposure to various types of cancer, including testicular, kidney, prostate, and bladder cancer.

While PFOAs, including PTFE, are becoming increasingly controversial, the availability of safer substitutes for these compounds is a positive sign for the PFAS industry. However, we should remain vigilant when it comes to identifying false advertising claims about PFOA or PTFE as safe.