3D printers are becoming increasingly popular and affordable, but using the machines remains a complex process. For example, most hobbyists will find it challenging to keep their 3D printers free from humidity and at the ideal temperature. Many might also struggle to comprehend if their filament requires a certain temperature or humidity level before printing. Considering that printer last longer when used at proper temperatures and humidities, 3D printers can enjoy greater control of their devices by using temperature and humidity monitoring and control equipment in the first place. Well, here’s how you can realize temperature and humidity monitoring and control in 3D printing to raise the life span of your device.

Overview Of 3D Printing Technology

1. Origin

3D printing is a manufacturing process that builds objects layer by layer. Traditional 3D printing uses plastic or other materials to create the object. But researchers are now developing ways to use liquid metal and food as a base material for 3D printing.

3D printing was once considered cutting-edge technology, but it has become so inexpensive and ubiquitous that it’s now used as a way to make prototypes for new products. It can also be used to make one-of-a-kind objects for art displays or personal use.

History of 3D printing

The first patent for stereolithography was filed in 1986 by Charles Hull, who worked at 3M (MMM). Hull was inspired by an article about inkjet printers and their ability to spray tiny droplets onto paper, leaving patterns behind them as they dried. He wondered if it would be possible to do something similar with ultraviolet light instead of ink, which led him down the path of inventing stereolithography.

Hull’s invention wasn’t commercially successful until 2008, when Stratasys acquired MakerBot Industries (MBTI) and began marketing its 3D printers under Fortus 900mc.

2. Application

.

3D printing technology is the process of making three-dimensional solid objects from a digital file. This technology is used for many applications in the medical industry, construction, aerospace, and many more.

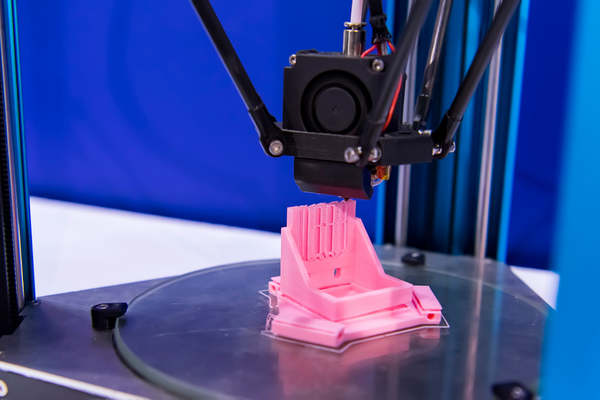

The most common method of 3D printing is called Fused Deposition Modeling (FDM). FDM uses an extrusion head that melts polymers (plastics) and deposits them layer by layer until a complete object is formed. The next step is to cool these layers with water or air, so they harden and bond together.

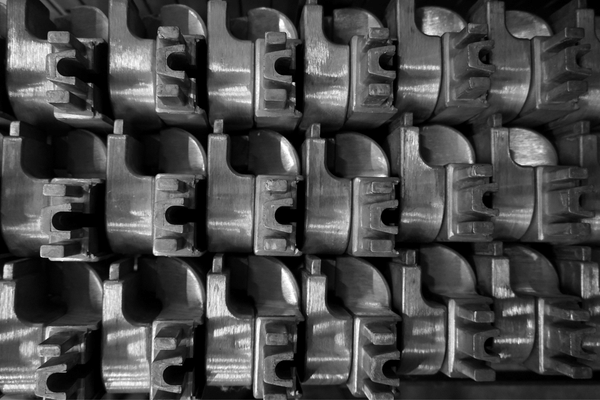

3D printing technology has been around since the 1980s, but it wasn’t until recently that it became affordable enough for most people to use at home or work. Today, hundreds of companies manufacture 3D printers ranging from small desktop units to large industrial systems that can produce thousands of parts daily!

Temperature Control Of 3D Printer

1. Heat transfer

Heat transfer is one of the most important parts of any 3D printer. Most materials used in 3D printing rely on heat to solidify them into their final state. This can be accomplished in several ways.

ABS plastic, for example, is heated up until it melts and then cooled down until it hardens into its final form. Other materials like nylon will not melt at room temperature but soften when heated to a certain temperature range. This process is called annealing and allows manufacturers to create parts with more flexibility than if they were printed from solid plastic or metal.

2. Temperature sensor

3D printing is a manufacturing process that builds three-dimensional solid objects from a digital file. 3D printers create prototypes and products in both commercial and consumer applications.

Technology has been used to produce everything from prosthetic limbs to human organs, which could significantly impact how we manufacture things in the future.

But how does it work? Here’s an overview of how 3D printing works:

1. Computer-aided design (CAD) software creates a digital model of the object you want to print. This model can be created by scanning an existing object or drawing something from scratch with CAD software.

2. The CAD file is then sent to the printer, which converts it into instructions for creating a physical object layer by layer using materials like plastic or metal powders or resins. The printer can build objects up to 12 inches cubed in size and with resolutions down to 0.001 millimeters thick for metal materials and 0.01mm for plastic materials.

3. Closed loop temperature control system

A closed loop temperature control system is a type of thermoplastic 3D printing technology that has become increasingly popular over the past few years. It uses a feedback loop to regulate the temperature of the extruder head and the build plate. This ensures that the printing material remains within its optimal printing range at all times, which improves print quality, reduces print time, and increases efficiency.

The closed-loop control system is generally combined with an open or semi-open loop system to achieve optimal results. This means that the printer can read the temperature of both the build plate and the extruder head at all times but only adjust them when necessary (i.e., when they go out of their optimal ranges).

Closed loop systems are also sometimes referred to as “smart” or “intelligent” systems because they allow users to adjust parameters such as temperatures in real-time based on feedback from sensors and other sources (e.g., humidity sensors).、

Conclusion

Based on the previous analysis, there are two major ways to deal with these problems: thermal management and humidity control. For thermal management, we can use an appropriate heat sink to improve the cooling performance of heat zones. This can achieve the goal of preventing excessive temperature rise within a 3D printer, especially around a nozzle region. As to humidification control, we can increase the dew concentration in the interior space air by adding some weather-controlled humidifiers that work on air conditioning systems or steam condenser principles.