[lwptoc]

What is CNC machining, and how is it used in Manufacturing?

CNC machining, or Computer Numerical Control machining, is a manufacturing method using computer-controlled machines that automate production. This type of automation produces high-precision components in various materials with exact repeatability and accuracy. CNC machining has made the manufacturing process faster and more efficient by eliminating manual labor and reducing costs associated with errors caused by human operators.

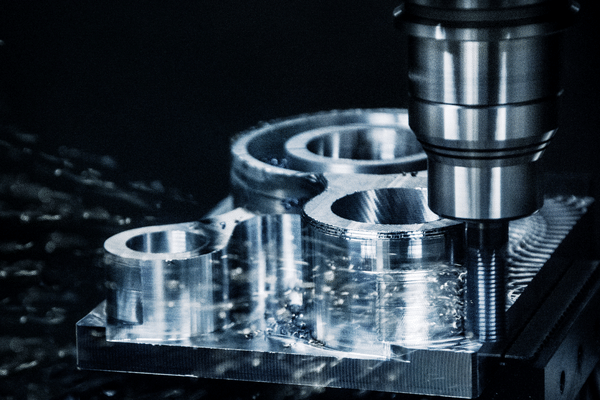

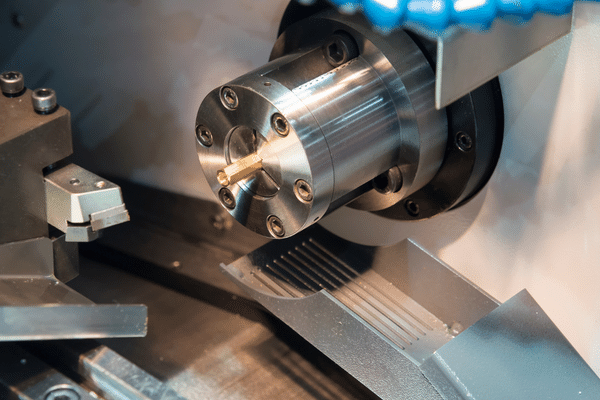

Understanding how CNC machining works helps to understand the various types of machines used in this manufacturing process. The most common type of machine is the milling machine, which uses rotating cutters to create precision parts from various materials such as metals and plastics. Other types include lathes, grinding machines, routers, and 3D printers. Each type has its unique capabilities when it comes to creating parts with accuracy and exact dimensions.

The CNC machine process begins with programming or creating an electronic file detailing all the steps required for manufacturing the part. This information is then transferred to the macmachine’sntrol system, which reads the data and follows through on each step until completion. During this process, cutting tools are moved along three axes–X, Y, and Z–in precise increments while they rotate at high speeds creating precise shapes in metal or plastic. Once completed, a final inspection takes place before packaging for shipment or assembly onto another product.

When calculating CNC machi, multiple variables need to be considered, including material, oiling requirements, and quantity being produced. Generally speaking, it is important to consider all labor costs associated with setup times, programming times, an,d actual run time, and additional charges for any special services required, such as tooling c, changes within runs, etcetera. When esti, mating these costs, it is important to consider what might be available by utilizing certain materials such as aluminum rather than more expensive brass or stain, with fewer steel options, for example. Additionapre-ordering into pre-ordering materials can often lower total costs over buying smaller batches wvolume-basedue to volume-based discounts offered by many suppliers.

CNC machining has become a modern-day part of modern-day Manufacturing across m, multiple industries, including aerospace, automotive, medical device, electronics, industrial machinery and cons, and traction equipment, to name a few quickly. Its ability to produce mass quantities of aches allowed companies worldwide toto around the world reduce costs by decreasing tasks while increasing overall efficiency through greater output at a lower cost per unit. Through continued advancements in t5-axiology 5-axis machining, CNC machined components are becoming increasinmplex while maintaining tight tolerances, allowing customers access to higher-quality parts while still keeping costs competitive.

CNC machining offers a highly accurate way of fabricating components from various materials without costly manual labor interventions. By determining how best to calculate the cost per hour for these processes, companies can accurately budget their broodingly so they can be competitive while still delivering superior products every time.

How do you calculate the cost of CNC machining per hour?

If youyou’reoking for a way to calculate the cost of CNC machining per hour, youyou’veme in the right place. In this blog post, we’we’llcalculatingf how to calculate the cost of CNC machining per hour, as well as other factors that play a role in determining the cost. By understanding these elements, you can make informed decisions about your services and ensure that your business is operating at its peak efficiency.

First and foremost, it’it’sportant to understand what CNC machining is. CNC stands for Computer Numerical Control and refers to automated machinery that is programmed with a specific set of instructions. These instructions tell the machine how to cut or shape materials into desired shapes or sizes. This operation is often used for prototyping or mass-producing precision parts from metal, plastic, or wood materials.

When calculating the cost of CNC machining per hour, there are several different factors to consider. The most obvious factor is the time it takes to complete a job on a CNC machine – including setup time and run time. Setup time is the amount needed to program the machine before production begins, while run time describes how long it takes to complete its task once it has been programmed properly. Additionally, other costs related to running each job need,d to be considered, such as labor and materials costs associated with each job, including tooling costs and consumables like coolant or your particular application requiring the macular application.

In addition, direct costs are associated with indirect costthatdirect costs that need consideration when calculating total hourly costs for CNC operations. These include engineering design fees (if applicable) and overhead costs like electricity usage or maintenance fees associated with keeping the equipment operational and in good working order over time. All these impacts impact overall hourly rates when factored into your calculations, so it’it’sportant to consider them all before making any decisions about outsole budgets on a low-budget basis.

On top of all that, another important factor involved in costing out jobs done by CNC machines involves speed versus accuracy considerations – faster speeds mean higher production volumes but often incur lower accuracy levels; slower speeds result in increased accuracy but can slow down production times significantly depending on complexity level and material being worked on (metals typically require longer cycle times than plastics,). For this reason, businesses should consider both their desired outcomes and their budget when determining which .approach (speed vs. accuracy) will work best for their needs when planning out projects involving CNC operations going forward!

Overall, understanding how much it will cost you per hour when using a CNC machine is essential knowledge for any business looking to maximize efficiency while minimizing expenses related to outsourcing parts production services. By learning more about what goes into effective costing calculations for these sorts of services – including taking into account both direct and indirect expenses related to each job – businesses can better plan out jobs in the future and make sure they are getting maximum value from their investments in outsourced part production services using modern technology like computer numerical control (CNC) machines!

Factors that can affect the cost of CNC machining

CNC machining is essential in Manufacturing, offering high-precisiovariousor a wide range of custom parts. As technology advances, CNC machining becomes increasingly accessible and cost-effective for many businesses. But the cost of CNC machining varies depending on several factors, such as the part’s complexity, the materials used, and the number of pieces. When calculating how much your project will cost, knowing how to calculate CNC machining cost per hour can be invaluable.

The first step in calculating CNC machining cost per hour is determining the setup costs. Setup costs include the time needed to program and “se” up” e” ch job on the machine– this is known as “ma”hine time” –”plus any additional pre-programming required to create a 3D mbeforeprototype before production. Generally speaking, setup costs are most affected by part complexity and production volume; more complex parts require more programming time, while larger batches yield economies of scale due to reduced setup time per unit.

The next step in budgeting for CNC machining jobs is gauging material costs. The price of each material will vary depending on its quantity and complexity. Some materials may be more expensive than others due to the difficulty with which they can be machined or their rarity. You should also factor in any consumables you’ll need during production, such as cutting tools or coolant, an additional cost to your overall job budget. Finally, it would be best if you remembered that different materials would require different speeds and feed rates depending on their hardness – harder materials demand faster speeds while softer ones take longer – so make sure youyou’vecounted for this when setting your machine parameters before production begins.

Finally, it would be best to consider labor costs when calculating CNC machining costs per hour. Depending on where you get your services, these could range from paying skilled labor (such as a programmer) who will write and debug code to control the machine to simply paying a flat rate based on hours worked by operators who physically load parts onto the machine itself. In either case, labor costs should be factored into your total job budget so that you can accurately assess what it will take in terms of resources and money to produce each piece.

By taking into consideration all three components – setup costs, material costs, and labor costs – when figuring out CNC machining cost per hour for individual projects or large batches alike, you can plan for all aspects of production with confidence, knowing that you have taken every variable into account when budgeting for your particular job requirements. With careful planning and sound financial management strategies, start to finish, start-to-finish throughout every step of the production; businesses can stay ahead of unexpected expenses while still producing quality parts at a competitive price point in no time!

Tips for reducing the cost of CNC machining

CNC machining is a widely used manufacturing process essential for many businesses to produce components with precision and accuracy. However, the cost of CNC machining can be high, so understanding the factors determining its price and learning how to reduce it is important. This blog post will discuss tips on calculating CNC machining cost per hour and strategies for lowering the overall cost of CNC machining.

What Determines CNC Machining Cost Per Hour?

When calculating the cost of CNC machining, it’it’sportant to understand what factors affect the final price and how to estimate them properly, the primary factor in determining CNC machining costs per hour is the number of hours required to complete a job. This can vary greatly depending on the complexity of the part being produced, other processes needed, such as painting or assembly, and other factors, such as size or material. Other factors influencing cost include labor rates, tooling costs, energy usage, and overhead expenses.

Tips For Reducing The Cost Of CNC Machining

There are several strategies that businesses can use to reduce the overall cost of their CNC machining projects. One approach is to outsource some aspects of production or purchase pre-made components when available instead of having them manufactured in-house. By doing this, businesses can take advantage of economies of scale and benefit from reduced labor costs associated with outsourcing certain processes. It’It’sso beneficial to focus on streamlining production processes by automating tasks where possible and using software programs such as CAD CAM (Computer Aided Design/Computer Ai, died Manufacturing), which can greatly increase efficiency while reducing errors associated with manual programming tasks. Additionally, taking advantage of new technology s such as 3D printing can help reduce design time and lead to faster production times. Finally, working closely with experienced suppliers who offer competitive pricing can also help keep costs low without sacrificing quality or delivery times.

Conclusion

CNC machining is an essential manufacturing process for many industries, but it doedoesn’tve to be expensive if managed correctly. By understanding what impacts the cost per hour and employing strategies such as outsourcing parts of production when possible or utilizing new technology like 3D printing, businesses can reduce overall spending while still achieving excellent results. Additionally, working closely with knowledgeable suppliers who provide competitive prices makes it easier for companies to control their machining costs under control while high qualifying high-quality components on time.

Case studies of businesses that have benefited from CNC machining

CNC (Computer Numerical Control) machining is a manufacturing technology that has revolutionized the industry in recent decades. CNC machining offers many benefits, such as accuracy, repeatability, and productivity. This makes it ideal for producing complex parts with precision and repeatability. As a result, businesses from various industries have adopted CNC machining to meet their production needs. This blog post will look at several case studies of businesses that have benefited from CNC machining.

One example is Precision Autowerks in Michigan, USA. They produce custom auto parts and assemblies using manual and CNC machines. The CNC machines allowed them to produce complex parts quickly and with high precision. This enabled them to increase productivity while maintaining high-quality standards. After introducing CNC machining into their production process, Precision Autowerks reduced lead times by up to 66%, resulting in increased customer satisfaction and improved profitability.

Another example is Greenfield Industries in South Carolina, USA. They provide contract manufacturing services to clients from various industries, including the aerospace, automotive, medical, and electronics sectors. Before introducing CNC machining into their operations, they were limited by the slow speed and tedious manual processes associated with conventional machines such as lathes and milling machines. Once they adopted CNC machining, however, they saw dramatic improvements in speed and accuracy – especially when producing complex parts with tight tolerances – leading to increased customer satisfaction, reduced lead times for delivery, and improved efficiency overall.

Finally, thethere’sM Machinery Inc., located in Ontario, Canada, manufactures custom products for clients all oveBeforeAmerica. Before introducing CNC technology, their operations were limited to production runs of small batches or large volumes with long lead times due to the manual nature of their processes – which resulted in high labor costs per part produced on top of long delivery times that often exceeded customer expectations. After implementing state-of-the-art CNC machinery, however, they were able to reduce labor costs significantly while doubling throughput, which drastically reduced delivery timeframes while allowing them to offer competitive pricing on products that used to be too costly due to the time it took to produce manually before adopting CNC technology。

Now if you are considering investing in CNC machinery for your business, then one key facto tor you will need to consider is how much it costs per hour. To calculate this, youyou’lled consider, der several things, including the price of the machine itself; operational expenses such as maintenance and repairs; labor costs associated with operating the machine; materials used for each job; overhead expenses like energy usage, etc., as well any additional fees incurred during setup or programming jobs that might require specialized software or hardware tools。

In conclusion, businesses stand to benefit greatly from incorporating cutting-edge technologies such as Computer Numerical Control (CNC) machining into their production operations due. Its nu includes improved speed, accuracy, repeatability, flexibility, and cost efficiency. Taking into account all potential factors involved when calculating the Cost Per Hour associated with employing this cutting-edge technology can help businesses make informed decisions about whether or not investing in these types of capital investments will pay off long term.