Introduction

Nylon is a high-strength polymer that’s both lightweight and flexible. It’s used in various industries, including manufacturing, aerospace, construction, and medicine. Nylon CNC machining is the process of using computer-controlled tools to shape nylon powders into components or products.

Why choose custom part services for nylon CNC machining?

We have the experience and expertise in machining many grades of nylon and can help you with your next project. We can help reduce your costs by utilizing our advanced machines and tools that will get your parts done faster than other methods, such as molding or injection molding, might be able to do! You’ll also benefit from our low price guarantee when ordering any custom part service at CustomPartServicesOnline! Our team works closely with clients every step of the way so we can ensure quality service at an affordable price point.”

What is Nylon CNC Machining?

Nylon CNC machining is a process that uses computer-controlled machines to cut, shape and mold raw materials. The process is used to create parts using a variety of materials. Some common examples include:

- Metal

- Plastic

- Wood

The process of nylon CNC machining involves creating the design for your part on a computer, then sending the data to a machine that will cut it out for you.

The benefits of using this process are that you can create complex parts in a very short amount of time. You also can make small or large batches of parts, depending on your needs.

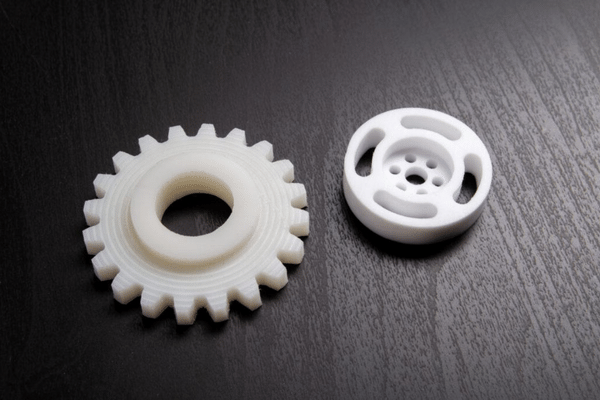

Additive Manufacturing with Nylon Material

Nylon is a material that can be used in 3D printing. It is commonly used in functional parts, such as gears and connectors. Nylon can be manufactured with different materials and processes, including powder bed fusion 3D printing.

If you want to manufacture nylon parts using additive manufacturing methods, you first need to know what these processes are and how they work. The second thing you should know about nylon manufacturing is its many benefits and limitations. These will help you determine if using nylon for your part production process will be beneficial or not.

Benefits of Nylon CNC Machining

Nylon is a strong, lightweight material that can be used in various industries. It’s easy to machine, and machining. It is one-way manufacturers can save time and money.

This is because nylon machines at a lower temperature than other materials like aluminum or steel, which means it doesn’t need as much energy to get through the material. This makes for faster sanding times, less heat build-up on your CNC milling cutter head, and less expensive electricity bills!

Why Choose Custom Part Services for Nylon CNC Machining?

- We have the experience and expertise in machining many grades of nylon.

- We can help you with your next project, whether it’s for prototyping or production.

- Our wide range of materials includes polyamide 66, 42, and 6 and polycarbonate (PC).

- We have many machines available—from vertical lathes to CNC mills and grinders.

- Our design team will help you ensure that your part fits your needs perfectly before we start manufacturing it.

We have the experience and expertise in machining many grades of nylon and can help you with your next project.

We have the experience and expertise in machining many grades of nylon and can help you with your next project.

We have been in business for over 20 years, and we’ve built a reputation for providing high-quality machined parts delivered on time and within budget. We are family owned and operated, which allows us to provide personalized service to every customer.

Our machine shop is one of the best-equipped facilities in Ohio, with state-of-the-art CNC equipment that includes:

- Haas VF-1 Vertical Machining Center

- Mazak VMC’s – 3 Mazak Integrex 300 machines & 1 Mazak Integrex 480 (with 5-axis capabilities)

- Mori Seiki Vertical Milling Machine (2 Axis)

What Are the Different Types of Nylon?

You may wonder, “What are the different types of nylon?” The answer to that question lies in understanding how nylon is manufactured. All types of nylon are derived from petroleum and have a polymer chain consisting of amide groups. These amide groups allow them to form into long-chain polymers that can be used in many applications.

Nylon comes in many forms,, such as fibers, films, and molded parts. Each type has its unique properties which make it useful for specific applications:

- Nylon 6: This polyamide resin has good flexibility and strength while maintaining high abrasion resistance. It’s also resistant to heat like boiling water or hot oil when applied correctly due to its unique chemical composition—the addition of sulfur during manufacturing helps improve strength properties while reducing brittleness or cracking issues seen with other types such as cellulose acetate.

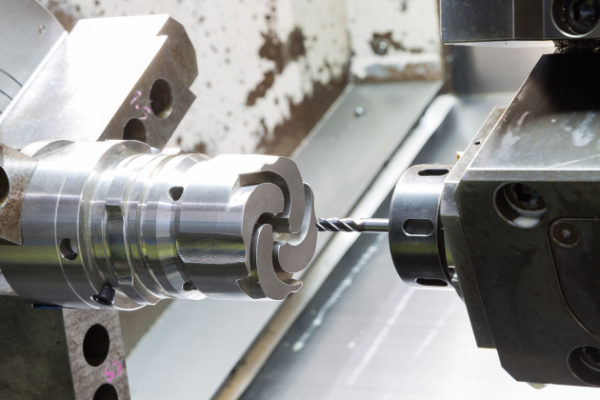

How Does CNC Machining Work?

CNC machining is a process in which a computer controls the movement of a machine tool to produce parts. The computer program is designed to cut or form the piece, and the CNC machine then uses this program to control its motion. This can be a lathe, milling machine, drilling machine, or any other machine tool that has been converted into a CNC for your project.

CNC machining tools are very precise because they do not require human input or supervision throughout production; however, it also means that every part produced needs to get specific instructions from you via CAD before they can begin work on your project (which means more planning). You will also need access to software with which you can create your design files if you want them done professionally instead of using manual methods like hand-carving clay models yourself!

How Much Does CNC Machining Cost?

CNC machining is a process that has been around for decades, but it is still one of the most popular ways to produce parts. The cost of nylon CNC machining will depend on the type and quantity of parts you need, but this process tends to be less expensive than machining other materials like metal or plastic.

Prices are based on material and quantity. To get an idea of what your project might cost, use our price calculator below:

Our price calculator is an easy way to get an estimate based on the dimensions of your part, material type, quantity, and any additional features. It will also help you determine if other manufacturing processes might be more cost-effective for your parts.

Conclusion

We are committed to helping you with your next project at Custom Part Services. Whether you’re looking for an affordable solution or something more complex, we have the experience and expertise in machining many grades of nylon that will help make your project successful. If you have questions about our services or want to learn more about CNC machining, please contact us today!