Aluminum is one of the world’s most versatile materials. It can be used for many applications, including construction and automotive manufacturing.

Aluminum offers many advantages over other metals. It is lightweight, durable, non-corrosive, and easy to form and machine. Aluminum is also a recyclable material that’s easy to recycle.

However, aluminum is a reactive metal that can be difficult to work with in some situations. This article will review five methods you can use for aluminum parts manufacturing.

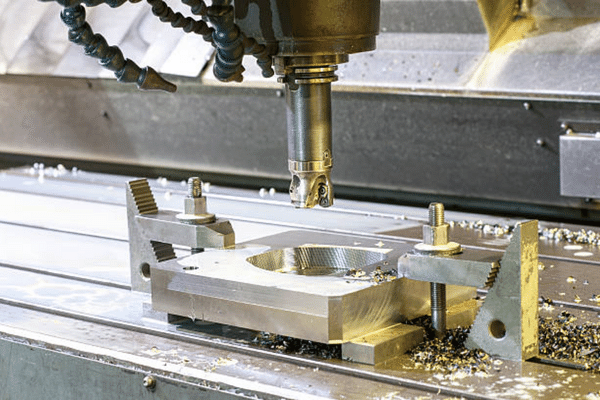

CNC machining

CNC machining aluminum parts is a very common practice among manufacturers. The reason for this is that aluminum is lightweight and easy to machine. It can be used in various applications, from aircraft and boat building to manufacturing automotive parts.

CNC machining aluminum parts offers several advantages over other methods of manufacturing. For example, it allows you to create complex shapes that are difficult or impossible to make using manual methods. In addition, it increases the accuracy of your parts because the computer-controlled machines can be programmed to cut with great precision. Finally, CNC machining offers high production rates with relatively low labor costs compared to other processes, such as forging or casting.

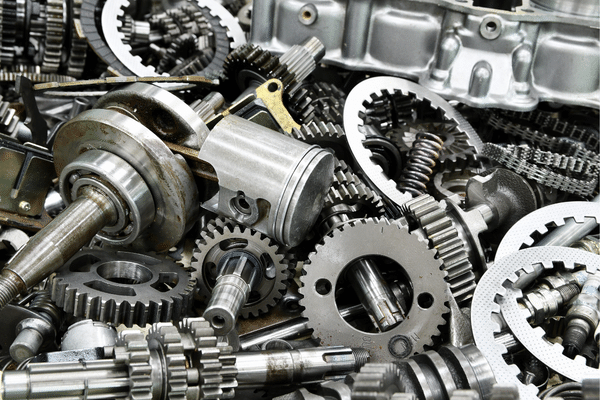

Casting

Casting is the most common form of aluminum parts manufacturing. Casting can be done with a variety of processes, including gravity die casting, pressure dies casting, centrifugal casting, and sand casting.

In gravity die casting, liquid metal is poured into a mold by gravity. Once the metal cools and hardens, the part is released from the mold. Gravity dies castings can be made in large volumes at low cost with good dimensional accuracy and surface finish.

Pressure die casting uses a high-pressure fluid to force molten metal into a mold cavity under pressure. This method produces more consistent flow than gravity dies casting and allows for greater tolerances on complex parts with thin walls or tight radii. Pressure die castings are used for engine blocks and cylinder heads in the automotive industry, as well as parts for other industries such as healthcare equipment manufacturing and small appliances like toothbrushes and hair dryers.

Forging

Forging is the process of shaping metal to form a part. In metal forging, the metal is heated to a high temperature and then shaped by force. The force can be applied manually or with the use of mechanical tools. Forging is used to create flat parts that are strong and rigid, such as engine blocks. Forged parts are more expensive than casted parts because they require more time and labor to make.

Forging is often done with aluminum alloys because these alloys are hard enough for the process but soft enough not to be damaged by them. Aluminum alloys have good mechanical properties (strength, stiffness, ductility) and can be work-hardened by cold working (heating then quenching in oil or water). They also have excellent corrosion resistance and high electrical conductivity, which makes them ideal materials for many applications, such as aircraft frames, body panels, and wheels.

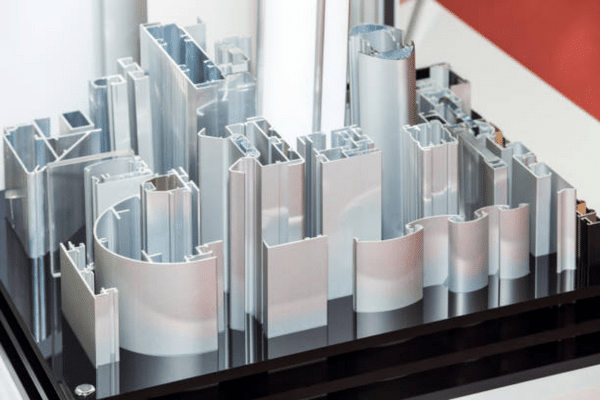

Extrusion forming

When it comes to aluminum parts manufacturing, there are many options available. Extrusion forming is one of the most widely used techniques for creating aluminum parts with complex shapes and high strength-to-weight ratios.

Extrusion forming can be done manually or with the aid of automation. Manual extrusion forming is a very labor-intensive process that requires trained workers and high levels of skill. Automated extrusion forming can produce more parts per hour and reduce overall costs.

Manual extrusion forming uses a die to shape the metal as it passes through it. The die creates a single part at a time. It requires skilled operators who must manually feed each piece into the die and then remove it once it has been formed.

Automated extrusion forming uses a series of dies arranged in a row to create multiple pieces simultaneously. Each die produces a single component, which is then fed into another die immediately after exiting the previous one. This process is repeated until all components have been produced.

Laser cutting

Laser cutting is a manufacturing process that uses a high-power laser beam to burn away materials. The laser beam can be controlled to create linear or contour patterns in a variety of materials. Laser cutting is used in aerospace, automotive, medical, electronic, and other industries to cut a wide range of materials, including aluminum alloys.

Laser cutting has several advantages over traditional machining processes such as milling and turning:

Precision: High-power lasers can cut to within microns (thousandths of an inch) of accuracy. This precision makes it possible to create parts that require complex geometries or have tight tolerances.

Speed: Laser cutting can be up to 100 times faster than traditional machining methods, such as milling or turning, which rely on mechanical cutting tools like carbide inserts or carbide end mills.

Cost: A laser cutter requires less setup and cleanup time than traditional machines do, so it’s more efficient overall, even though it costs more per part than conventional machining methods do.

Waterjet cutting

Waterjet cutting is a relatively new technology that has been gaining ground in the manufacturing industry for its ability to cut an almost unlimited number of materials with high precision.

Waterjet cutting is a type of industrial process that uses superheated water and abrasive particles to cut through materials such as aluminum, stainless steel, titanium, carbon fiber, glass, and more. The material being cut is placed in between two nozzles at opposite ends of the machine with a thick sheet of water between them. The nozzle on one end shoots out a high-pressure stream of water, while the nozzle on the other end shoots out abrasive particles that are used to cut through the material. When these two streams collide, they form a sort of plasma jet that cuts through most materials very quickly with little waste or debris left behind.

The advantage of using this method over traditional machining methods is that it uses less energy than traditional machining processes while still allowing you to achieve extremely high tolerances with great accuracy. Waterjet cutting machines can also be programmed to make many different shapes and forms that are impossible to make using conventional machining processes due to their ability to produce complex geometries.

Conclusion

Stylish aluminum parts look great, are inexpensive, and have multiple uses. However, designing for fabrication and assembly can be

challenging. The above steps will guide the creation of aluminum parts.