The Basics of Sheet Metal Workshop

Sheet metal is a thin layer of metal that can be cut, bent, and welded. Sheet metal is used in many different industries, including construction and manufacturing. Sheet metal workers are responsible for cutting, shaping, and welding this material into whatever form is needed.

Sheet metal workers use several different tools to perform their jobs. These include:

Cutting torch – This tool uses an arc of electricity to cut through the sheet metal. It can be used to cut large sheets or small pieces of sheet metal at once.

Bending brake – This tool can be used to bend large sheets of sheet metal into different shapes. It uses hydraulic pressure to force the material into place as it’s being bent by hand or by machine.

Welding gun – This tool uses electricity to melt pieces of steel together so they become one object instead of two separate pieces. The gun heats up the steel so that it melts when coming into contact with another piece of steel or other metals like aluminum or copper.”

What You Need to Know Before Starting Your Sheet Metal Workshop

If you’re looking to start a sheet metal workshop, you’re probably wondering how much it will cost. While this is a great question, it’s not the only one you should be asking yourself before getting started.

What do you need to know before starting your sheet metal workshop? Here are a few things to consider:

How much money do I need? This is the most important thing to consider when starting any business—how much money will I need in order to get started? You don’t want to run out of funds before you even begin working on your idea. If this happens, it can be devastating for your business and cause many other problems down the road.

How can I get funding and loans? If you don’t have enough money in your bank account or savings account, there are ways for you to get funding and loans so that you can start working on your project right away! There are many resources available online which offer free information about different types of financing options available today; however, these resources may not always be accurate so make sure that all information is verified before signing any documents with any lender/company offering these services.”

Working with Different Types of Sheet Metal in the Workshop

Working with different types of sheet metal in the workshop can be a challenge, but it’s important to remember that there are a few key things to keep in mind when you’re working with these materials.

First of all, you need to be aware of the weight and thickness of the sheet metal at all times. This is because if it’s too heavy or too thin, you won’t be able to handle it safely.

Second, make sure that your work surface is level and sturdy enough to support the sheet metal without buckling or cracking. If your table isn’t secure enough, you might end up with a broken piece that isn’t usable at all!

Third, make sure that your tools are sharpened before using them on any type of metal! Dull blades will cause more damage than good when trying to cut through thick pieces like these because they won’t cut through smoothly without causing friction which can lead to breakage later on down the road.”

How to Protect Yourself from the Hazards of a Sheet Metal Shop

In the work environment, it’s important to know how to protect yourself from the hazards of a sheet metal shop. Sheet metal is used in a wide variety of products, from cars to airplanes. Sheet metal workers are exposed to many different types of hazards, including noise and vibrations, extreme temperatures and humidity, repetitive motions, heavy lifting and carrying loads up to 50 pounds, electrical hazards such as electric shock or arc flash burns, and even chemical exposure from welding fumes.

Here are some tips for staying safe in a sheet metal shop:

1. Wear protective equipment at all times while working with sheet metal. This includes thick gloves that protect against cuts and punctures; hard hats with chin straps; goggles; ear protection devices; flame-resistant clothing; steel-toed boots or shoes; leather aprons; leather gloves; respirators (for welding); and dust masks with cartridges that filter out harmful particles in the air (like asbestos).

2. Wear proper clothing when working with sheet metals—this includes long pants (no shorts), sleeves rolled up above elbows, long-sleeved shirts/jackets (no short sleeves), and closed-toe shoes with thick soles so you don’t trip over things like nails sticking up out of boards on which you walk

Essential Tools for Operating a Successful Sheet Metal Workshop

Essential Tools for Operating a Successful Sheet Metal Workshop

Sheet metal is a versatile material that can be used to produce many different types of products. It is often used in the manufacturing of tools, appliances, and vehicles. However, it is important to remember that sheet metal is not actually a single type of material. Instead, it refers to a group of different types of materials that have been formed into sheets and other shapes by rolling or pressing them into place.

If you are looking to start your own sheet metal workshop then you will need some essential tools to get started. These tools will help you make sure that you have everything you need to succeed at your new business venture. Some of these tools include:

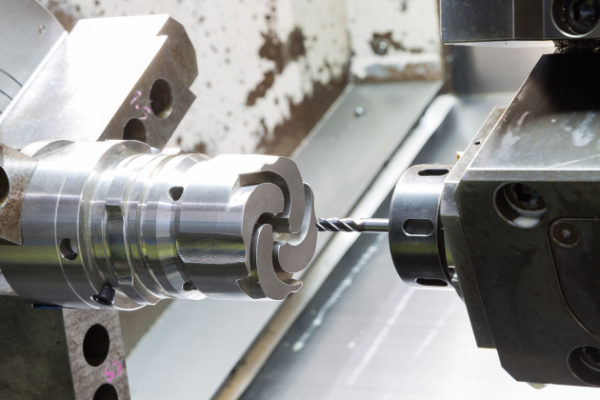

1) Cutting tools – Cutting tools such as shears and band saws are essential when working with sheet metal because they allow you to cut pieces into smaller parts without damaging the integrity of the piece itself. These cutting tools can also be used on other materials besides just sheet metal so they are quite versatile as well! Some examples include:

2) Welding equipment – Welding equipment such as torches and welding rods are also necessary when operating a successful sheet metal workshop because they allow you

Design Tips and Tricks for Crafting Intricate Sheet Metal Projects

Design Tips and Tricks for Crafting Intricate Sheet Metal Projects

Designing intricate sheet metal projects can be a great way to demonstrate your skills in the field of design. The important thing to remember when designing a project is that you need to make sure your project is easy to understand, even if it looks complex. If your design is too complicated, it will be difficult for people who are not familiar with the project to understand what’s happening.

One way to make sure that your design is easy to understand is by using simple shapes and lines. You can also use color to highlight important parts of the design so that it doesn’t get lost among other elements on the page or in an online document. Another option would be to use bold lettering at key points throughout the document so that people know where they should focus their attention when reading through documents related to your work.

If you’re working with a client who wants something more complicated than just basic shapes and lines, then consider adding icons or other visual elements as well as text descriptions that explain what each icon means within context of each other so that readers can easily understand what each icon means without having any prior knowledge about what each symbol represents before reading through your document(s).

Optimizing Your Equipment for Maximum Efficiency in Your Sheet Metal Shop

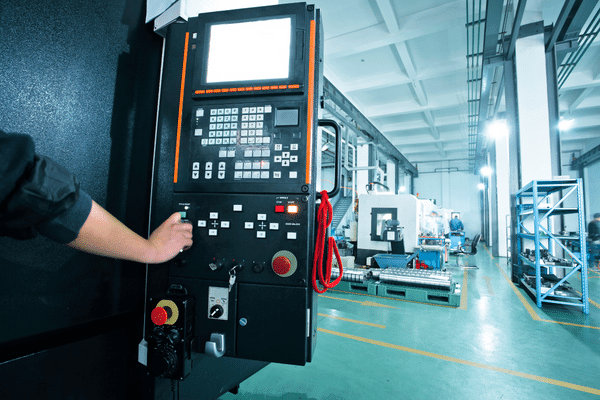

One of the most important aspects of running a sheet metal shop is ensuring that you are using your equipment to its fullest potential. This will not only help you save time and money, but it will also make it easier for you to provide quality work to your customers.

To optimize your equipment, you should first evaluate the processes that are used in the shop. This includes evaluating the number of production lines in use, as well as how many different types of work are done on each line. It is also important to consider how many employees are needed for each line and what their roles are.

Once these evaluations have been completed, it is time to make some changes! The first step is to figure out what needs improvement and how much time can be saved by implementing these changes. You should also take into account any other factors that may impact your business such as location or competitors who offer similar services.

Once these factors have been considered, there are many ways you can optimize your operations including: streamlining processes by eliminating waste; automating processes so they require less human labor; increasing efficiency through automation; reducing waste through recycling programs; increasing employee productivity through training programs; improving safety measures within the workplace; implementing technology such

Streamlining Your Processes to Increase Productivity in the Sheet Metal Workshop

To streamline your processes in the sheet metal workshop, you need to identify each step in the process and determine how it can be performed more efficiently. Then, you can develop a plan for implementing those changes.

The first thing to do is to create a list of all steps involved in completing a project. For example, if you’re making a part for a car, there will be many different steps that go into making that part: designing it, cutting it out of metal using a machine called a shear or press brake (if it’s flat), bending it by hand using another machine called an English wheel or C-brake (if it’s round), welding it together with other parts and so forth.

Next, you need to break down each step into smaller tasks and assign them to specific individuals or teams of people. Then you need to figure out how long each task should take based on past experience, calculate how long it will take for everyone working together all at once (this is called “work flow time”), and subtract that number from the total amount of time available between now and when the job must be completed (this is called “pull time”).

You’ll know whether or not your new system works when you compare pull times with work flow times

Safety Measures All Sheet Metal Workers Should Be Aware Of

All sheet metal workers should be aware of the safety measures they need to take to prevent serious injury. For example, they should wear protective gear at all times and avoid handling any materials that are hot or sharp. They should also ensure that their work area is well-lit and free of potential hazards, such as electrical wires or sharp objects.

Sheet metal workers may be exposed to a number of different hazards on the job, including:

· Burns from hot surfaces or molten metal

· Cuts from sharp edges

· Injuries due to falls off ladders or scaffolds

· Burns from cutting tools such as saws and drills

Troubleshooting Common Issues in the Sheet Metal Workshop

Troubleshooting Common Issues in the Sheet Metal Workshop

The sheet metal workshop is an essential tool for any manufacturing company. It is used to cut, bend, and shape metal into various shapes and sizes. However, there are many common issues that can occur while using this machine. The following list contains the most common issues that arise while using a sheet metal workshop and their solutions:

1. The first issue that can occur when using a sheet metal workshop is that it may not cut through the metal correctly. This problem can be solved by adjusting the blade depth so that it cuts through all layers of metal without any problems.

2. Another common issue with sheet metal workshops is that they do not cut straight lines due to having uneven pressure on both sides of the blade. This problem can be solved by adjusting both sides of the blade so they match each other equally in terms of pressure being applied to them during cutting operations (i.e., one should not be harder than another).

3. Another issue that arises when using a sheet metal workshop is having too much tension on one side of your material during cutting operations (i.e., causing only one side to get cut off instead). This problem can be fixed by loosening