What is the purpose of the Cnc Milling Service China ?

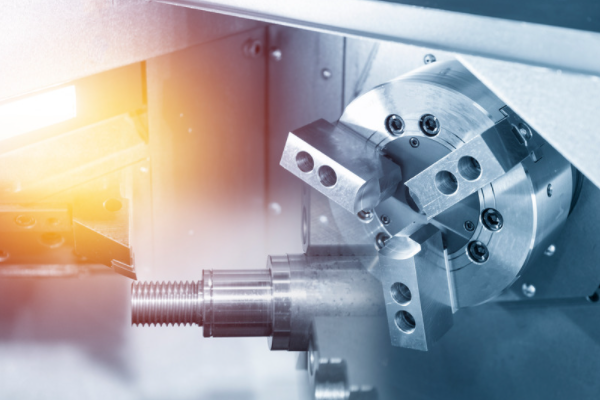

The CNC milling service China is a service that can be used to make various products. The process of making the product begins with the design of the product, then it is cut into digital tools that are used during the manufacturing process.

The general purpose of this service is to create complex shapes from metal, plastic or wood materials. CNC milling is also known as computer numerical control (CNC) machining, which refers to automated machine tools that use computers for their operation.

The main components of this process include: milling machine, software program and computer control system. In addition to this, there are many other important factors that need to be considered before using this type of tool such as: material type, tolerance requirements and so on. The process of CNC milling is an automated method for making a wide range of parts from metal and plastic. This technology is widely used in industries such as aerospace, automotive, medical, marine and construction.

CNC milling is also used extensively in the manufacture of small parts and complex structures. CNC machining is mainly used for producing components with precise geometry, high accuracy and close tolerances. This process can be used to produce both solid and hollow parts with different materials.

What materials will be machined by Cnc Milling Service China ?

What materials will be machined by Cnc Milling Service China ?

1. The main machine is used to mill the material, and the auxiliary machining equipment is selected according to the material and process requirements.

2. Select a good quality material for the workpiece. It should be processed under certain conditions, such as being ground or machined with other equipment.

3. Determine whether you need a dedicated line for each task or whether you can use an existing line.

4. Identify the finished product size and shape, as well as its tolerance range, so that it matches the requirements of your design drawing; if not, then ask your sales representative for advice on how to achieve your desired result with our Cnc Milling Service China products and services. 5. Decide whether you want to use an existing machine or have new machines built for your project.

6. Identify the type of material you want to use and the supplier from whom you will purchase it. 7. Create a detailed list of all materials required for your project; this will help ensure that everything is ready when needed and nothing is forgotten or overlooked at any stage.

What tolerances are required for the finished parts ?

When we make Cnc Milling Service China products, we have to ensure that they have the correct tolerances. This is because if the tolerances are too loose, then it can cause a lot of problems with the operation of the finished product. If they are too tight, then it will not be as effective or efficient as it could be.

The following steps should be taken:

1) Make sure that all parts of the product are measured and marked correctly before any cutting begins. This ensures that all dimensions are accurate and consistent throughout manufacture.

2) Once cutting has begun, check periodically to make sure that there are no errors in the measurements or marking process. If there are any issues with these processes at any point during manufacture, this should be reported immediately so that it can be corrected immediately before further damage occurs to other parts of your Cnc Milling Service China product line-up (this could include reduced efficiency from one piece not fitting properly into another).

3) Inspect each part carefully when finished manufacturing has been completed and make sure that all pieces fit together properly before shipment takes place; if there are any discrepancies between pieces (such as those mentioned above), they must be corrected before shipping takes place. 4) Make sure to create a detailed and accurate bill of materials for each part, so that you can keep track of which ones are missing or damaged during shipment and whether or not they were reported by your CNC machine before it left the warehouse.

5) When you receive the shipment back, check it thoroughly to make sure that all parts are accounted for and that they were not damaged during shipping. If there are any discrepancies between your inventory and the bill of materials, you must immediately report them to the manufacturer so that they may be corrected before sending out another shipment.

Are there any special features or requirements for the parts ?

Step 1:

The CNC milling service is a high-precision, automated process that uses computer-controlled cutting tools to remove small amounts of material from a workpiece. The CNC milling process uses a variety of tools, including end mills, drill bits and reamers to create an accurate and precise final product.

Step 2:

CNC milling is used for the production of many different parts, including engine blocks, camshafts and crankshafts. It can also be used in the creation of custom parts like molds or dies. CNC milling allows manufacturers to produce precise parts quickly and efficiently.

Step 3:

CNC milling is also used in production environments where there are many different parts being produced at once. In these situations, it may be necessary for all of the parts to have identical features or dimensions so they will all fit together properly when assembled into a final product. Step 4: CNC milling is used to create many different parts, including engine blocks and crankshafts. This process allows manufacturers to produce precise components quickly and efficiently. Step 5: CNC milling can also be used in production environments where there are many different parts being produced at once. In these situations, it may be necessary for all of the parts to have identical features or dimensions so that they will fit together properly when assembled into a final product.

Step 6: CNC milling is used to create many different parts, including engine blocks and crankshafts. This process allows manufacturers to produce precise components quickly and efficiently. Step 7: CNC milling can also be used in production environments where there are many different parts being produced at once. In these situations, it may be necessary for all of the parts to have identical features or dimensions so that they will fit together properly when assembled into a final product.

What delivery schedule is required ?

Cnc Milling Service China is a professional CNC milling service provider in China. We provide you with high quality products and professional services.

We have been providing CNC milling services for nearly two decades, and we are well known in the industry for our expertise and ability to meet deadlines. We have many satisfied clients who rely on us to deliver their parts on time, no matter how complex the project is or how tight the deadline is.

We are able to meet these demands because of our highly-trained workforce and state-of-the-art equipment. Our workers are experienced and skilled at what they do, which means that they can take on any job with ease. They have access to powerful tools that allow them to work quickly and efficiently without sacrificing quality or timeframes.

Our goal is always on time delivery of your project because it’s important that you receive your products as quickly as possible so that you can get back to business! Our commitment to quality is reflected in our products. We strive for perfection, which means that no matter what you order from us, it will be of the highest quality. We ensure this by using only the best materials and following strict guidelines during production so that every part is exactly what you need. Whether you need a few parts or hundreds of thousands of them, we have them ready for shipment within 48 hours!

We have the ability to manufacture parts with a variety of different materials, including plastic, metal and glass. This means that you can use us for any kind of project that requires custom-made parts! Our in-house design team is always available to help you choose the right material and style for your project. We work closely with our customers to ensure that they receive exactly what they need every time.

How many parts are needed in total ?

Step 1: The first step is to determine the number of parts that will be needed for your product. If you have a 3D model of the product, then you can use this to determine the number of pieces that must be cut out of material. If you do not have a 3D model, then you can measure each part by hand or use other methods such as a grid system or mathematical equations.

Step 2: Determine how many materials will be needed to make your product. This includes any parts which are made from metal, plastic or wood as well as any screws or other fasteners which may be required for assembly of these parts together later on down the line once they’ve been produced out of their own separate materials first before being joined together into one final product altogether (which would mean having these separate materials all glued together then glued onto something else altogether just like in some kind of assembly line process). For example: if there’s a wooden table with four legs on top plus three drawers underneath each one both below these legs plus one drawer on top underneath them also; then there’s going to be a lot of different parts needed for assembly in order to put this table together. These include the legs themselves plus their corresponding drawers on top underneath them (as well as any screws or other fasteners which may be required for assembly of these parts together later on down the line once they’ve been produced out of their own separate materials first before being joined together into one final product altogether (which would mean having these separate materials all glued together then glued onto something else altogether just like in some kind of assembly line process).

In order to make these tables, we need to know what all of the parts are going to be, how many of them there will be in total (as well as the size and weight of each one of them), what material they should be made out of (which would then determine just how durable this table is when it’s finished being assembled together with all its various parts), as well as any other information which may come up later on down the line once we get started with actually making this table ourselves or else having someone else do so instead.