[lwptoc]

1. What is aluminum milling?

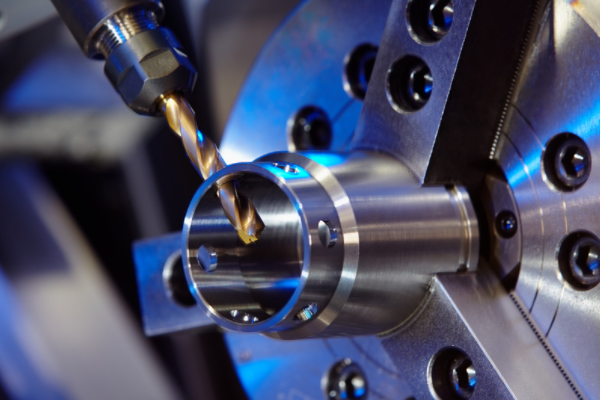

Aluminum milling is the process of shaping aluminum by removing metal with a cutting tool. The process can be done manually or mechanically, and involves a number of different tools.

Hand-milling is the most common form of aluminum milling, and it’s often used to create decorative items like sculptures and furniture. When hand-milling, you will use a drill press to hold your work while you cut it; this keeps the piece steady while you are working on it. To perform hand-milling, you will need an assortment of files, saws, and other tools that help you shape your material into its desired form.

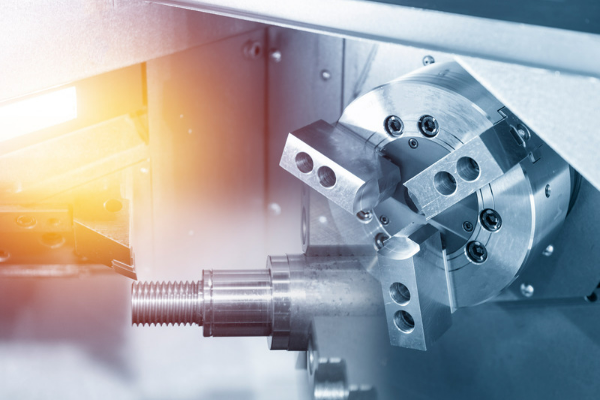

Machine milling is done using a machine called a lathe; this machine allows for more precise cuts than hand-milling does because it has specialized tools that make it easier for you to create complex shapes out of small pieces of material without sacrificing quality or finish,”

2. What types of aluminum can be milled?

The types of aluminum that can be milled depend on the type of milling machine being used. If you have a special type of milling machine, you’ll be able to mill many different types of aluminum. However, if you have just a standard milling machine, then it won’t work for every kind of aluminum.

There are two main types of mills: manual and automated. Manual mills are those in which the operator manually controls the movement of the tool while it’s in use; automated mills are those that are controlled by computers that allow for more precise movements. The most common type of manual mill is called a horizontal mill because it looks like an elongated table with a circular hole in it where the part is placed into so that it can be machined. Automated mills tend to be vertical rotary or vertical spindle; these machines use rotating tools instead of rotating parts like their horizontal counterparts do because they’re more efficient at cutting through metal than they are at grinding away material from one side at a time (which is what this style does).

3. What are the benefits of aluminum milling?

Aluminum milling is a process that uses a milling machine to shape the metal. It is used to create custom parts for all sorts of applications, including medical devices, food processing equipment, and aircraft components.

The benefits of aluminum milling include:

-Improved accuracy and surface quality – The milling process creates smooth, flat surfaces with minimal burrs or rough edges. This means that your part will be more attractive and easier to assemble than parts that have been created by other methods.

-Lower tool costs – Milling machines are very precise and can produce many different types of shapes and sizes for less money than other tools would cost you. For example, if you need to produce 100 parts at once, your cost per piece will be less if each part is milled rather than cast or molded.

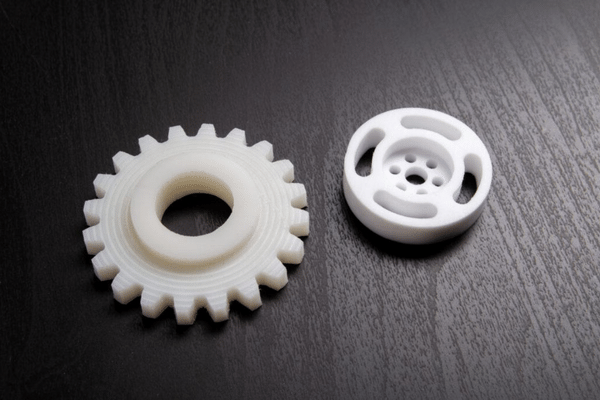

-Rapid prototyping – Because milling can be done quickly, it’s easy to use as a way to prototype products before mass production begins. You can use the same design files over and over again until you’re ready to move forward with full production.

4. What types of tools are used for aluminum milling?

Aluminum milling tools are manufactured using a variety of materials, including carbide, cobalt steel and tungsten carbide. The choice of material is based on the specific process being used and the type of aluminum being milled. The tool will be designed with a specific shape or geometry to provide the desired cut quality and surface finish.

Carbide tools are used for materials that are difficult to machine, such as hardened steels and high-strength alloys. These tools can be made from either cemented or solid carbide. Solid carbide tools contain more tungsten than cemented carbide, so they offer higher strength at higher temperatures than cemented carbide.

Cobalt steel tools are used for aluminum alloys with high strength and hardness values because they have good wear resistance and toughness characteristics at elevated temperatures. Cobalt steel tools offer great durability due to their ability to resist fatigue under heavy loads when compared to other types of milling tools used for milling aluminum alloys.

5. What is the typical turnaround time for an aluminum milling service?

The turnaround time for an aluminum milling service depends on the process that you need to be done. The most common services are:

1. Aluminium Grinding Services (Aluminium Crusher)

2. Aluminium CNC Machining Services (Aluminium Milling)

3. Aluminium Turning Services (Aluminium Lathe)

4. Aluminium Drilling and Milling Services (Aluminium Boring)

5. Aluminium Welding Services (Aluminum Welding)

6. What is the cost of an aluminum milling service?

The cost of an aluminum milling service is dependent on a variety of factors. Some of these include the size, shape, and complexity of the piece being milled; whether the milling service is being performed in-house or at a third-party facility; and whether there are any special materials that need to be used during the process.

For example, if you are looking to have a complicated part cut out of aluminum, then it will cost more than if you were trying to have something simple done. If you want your parts done locally, then it will cost less than if you want them done at an outside facility. Additionally, if you want them done with a specific material (like stainless steel), then that will also increase the price tag.

7. Are there any special considerations when milling aluminum?

Yes, there are a few special considerations when milling aluminum.

First, it’s important to use carbide tooling, as this will ensure that you get the best possible results. Carbide is much harder than the aluminum itself, so it can withstand the rigors of machining without being damaged. It also has better durability and longevity than high-speed steel or cobalt steel, which means you’ll be able to use your tools for longer periods of time and with fewer breaks in between uses.

Second, keep in mind that aluminum has a tendency to heat up quickly under pressure from the cutter head. This can cause problems with your tooling: if it gets too hot, it can lose its hardness and become brittle; if it gets too cold, it can break more easily than usual. You’ll want to make sure that you’re keeping an eye on things while they’re happening so that you can adjust accordingly as necessary—this means checking in regularly with your milling machine and making sure everything looks good every few minutes or so during each operation; if something doesn’t look right after a few minutes have passed by since your last checkup (and you’ve made no changes since then), stop what you’re doing immediately and check things out before continuing again

8. What safety precautions should be taken when milling aluminum?

When milling aluminum, it is important to follow the following safety precautions:

1. Use the proper PPE. All personnel working with aluminum should wear protective eye wear and respirators while they are working with the material.

2. Never store aluminum in a container that has previously contained anything flammable, toxic, or otherwise hazardous. This includes gasoline and other fuels.

3. Always wear gloves when handling aluminum or any of its byproducts such as dust or shavings.

4. Avoid contact with eyes and skin by wearing protective gear at all times when handling aluminum products such as ingots, casting ingots, billets, etc..

9. What is the best way to ensure quality when using an aluminum milling service?

Ensuring quality when using an aluminum milling service is a matter of making sure that you fully understand the process and the materials, as well as what you are trying to achieve.

The first step is to make sure that you know exactly what kind of aluminum alloy you want to use. Different alloys have different properties and different uses, so it is important to choose the right one for your project. Once you have chosen your alloy, it is time to think about how that alloy will be used in your product. This will help you determine which type of milling process would be best suited for your needs (e.g., whether or not the finished product needs to be painted).

Once these decisions are made, it is time to make sure everything is done by an experienced professional with plenty of experience working with this type of material. It is also important to choose someone who has experience working with other clients in similar industries as yours so they can offer advice on how best to proceed with your project without breaking any rules or regulations that may exist within those industries.”

10. Are there any special techniques used for milling aluminum?

When milling aluminum, there are some key considerations that need to be made. First, it is important to remember that milling can be a hazardous process. The dust created by the cutting process can be hazardous if inhaled and may cause irritation. Also, some of the particles may be toxic, so it is important to wear protective clothing including gloves and goggles when working with aluminum.

The second thing to consider when milling aluminum is that it tends to create an oily residue on the cutting tool which can make it difficult to cut accurately. To prevent this, it’s best to use a lubricant such as soap or oil on the cutting tool before beginning work. You should also clean off any residue that accumulates on your tool regularly throughout the day with a solvent such as acetone or alcohol so that it doesn’t build up and interfere with your cuts later on in the day (or week).

If you need cnc maching service from china , please contact us